- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

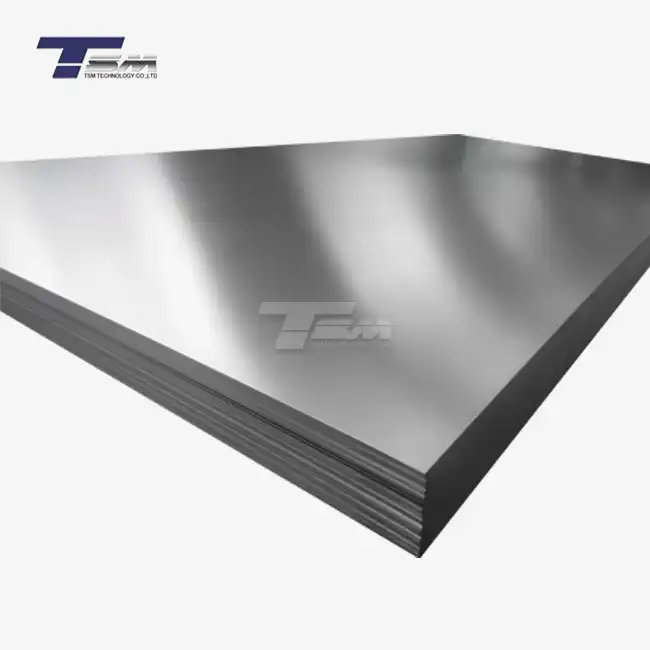

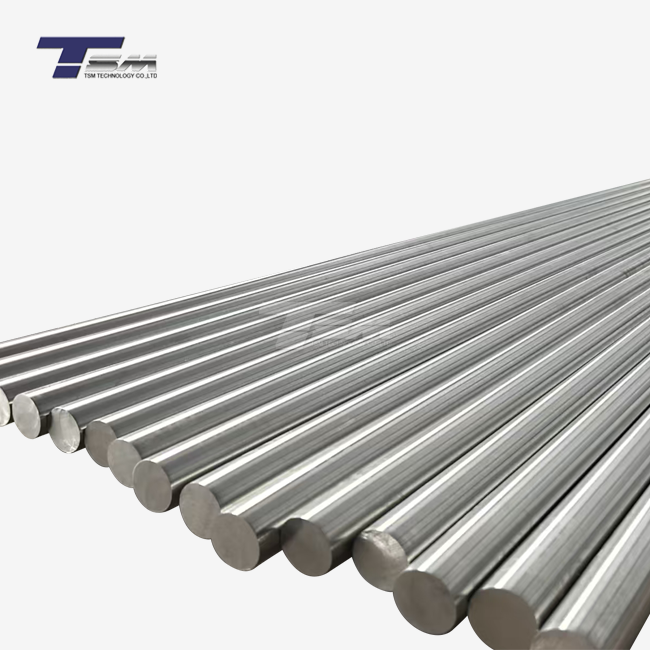

How to Shear Monel 400 Sheet Without Deformation?

Shearing Monel 400 sheet without deformation requires a combination of proper techniques, appropriate tools, and careful consideration of the material's properties. To achieve clean, precise cuts while maintaining the sheet's integrity, it's crucial to use sharp, well-maintained shears or guillotine cutters specifically designed for high-strength alloys. Ensure the cutting equipment is set up with the correct clearance and blade angle for Monel 400's thickness and hardness. Lubricating the cutting edge can reduce friction and heat generation during the shearing process. Additionally, maintaining a consistent, controlled cutting speed and applying even pressure throughout the cut will help minimize deformation. For thicker Monel 400 plates, consider using alternative cutting methods such as waterjet or laser cutting to achieve optimal results without compromising the material's structural integrity.

Understanding Monel 400 Properties and Shearing Challenges

Composition and Characteristics of Monel 400

Monel 400 is a nickel-copper alloy renowned for its exceptional strength, corrosion resistance, and versatility. Composed of approximately 67% nickel and 31% copper, with small amounts of iron and manganese, this alloy exhibits remarkable durability in various demanding environments. Its unique composition contributes to its high tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 585 MPa), and yield strength of about 25,000 to 50,000 psi (170 to 345 MPa).

The alloy's work-hardening characteristics and ductility make it both a desirable material for numerous applications and a challenge when it comes to shearing. Monel 400 sheets possess excellent malleability and can be formed into complex shapes without losing their inherent properties. However, this same quality can lead to potential deformation issues during the shearing process if not handled correctly.

Common Challenges in Shearing Monel 400

When shearing Monel 400 sheets, fabricators often encounter several challenges that can lead to deformation or unsatisfactory results:

- Work hardening: Monel 400's tendency to work harden during cutting can cause localized stress and potential deformation.

- Edge burring: Improper shearing techniques may result in burrs along the cut edge, requiring additional finishing processes.

- Thickness variations: Inconsistent sheet thickness can lead to uneven cuts and potential deformation.

- Tool wear: The alloy's hardness can accelerate wear on cutting tools, affecting cut quality over time.

- Heat generation: Excessive heat produced during shearing can alter the material's properties near the cut zone.

Importance of Proper Shearing Techniques

Employing the right shearing techniques is crucial for maintaining the structural integrity and dimensional accuracy of Monel 400 sheets. Proper methods not only prevent deformation but also ensure clean cuts, reduce the need for secondary finishing operations, and extend the life of cutting tools. By understanding the material's behavior and adapting shearing practices accordingly, fabricators can achieve high-quality results while maximizing efficiency and minimizing waste.

Essential Tools and Equipment for Shearing Monel 400

Selecting the Right Shearing Machine

Choosing the appropriate shearing machine is paramount when working with Monel 400 sheets. Hydraulic shears are often preferred for their ability to deliver consistent force throughout the cutting stroke. Look for machines with adjustable rake angles and blade gap settings to accommodate different thicknesses of Monel 400 plate. For precision cuts on smaller pieces, a bench-mounted shear with hardened blades may be suitable. Ensure the machine's capacity exceeds the maximum thickness and width of the Monel sheets you'll be working with, typically by at least 25% to provide a safety margin.

Blade Materials and Maintenance

The choice of blade material significantly impacts the quality of cuts and the longevity of your shearing equipment when working with Monel 400. High-speed steel (HSS) blades with a hardness of at least 60 HRC are recommended for their durability and ability to maintain a sharp edge. For even better performance, consider using carbide-tipped blades, which offer superior wear resistance and can maintain their cutting edge for longer periods when shearing tough alloys like Monel 400.

Regular maintenance of shearing blades is crucial:

- Inspect blades before each use for signs of wear or damage

- Sharpen or replace blades at the first sign of dullness to prevent deformation

- Clean blades thoroughly after use to remove any metal particles or debris

- Apply a thin layer of cutting oil or lubricant to prevent corrosion during storage

Auxiliary Equipment for Precision Shearing

To enhance the precision and efficiency of shearing Monel 400 sheets, consider incorporating these auxiliary tools and equipment:

- Back gauges: Ensure consistent and accurate positioning of the sheet for repeatable cuts

- Material supports: Provide proper sheet support to prevent sagging and maintain flatness during cutting

- Digital measuring devices: Use calipers or micrometers to verify sheet thickness and cut dimensions

- Sheet handling equipment: Employ vacuum lifters or magnetic lifters designed for non-ferrous materials to safely manipulate large Monel 400 plates

- Deburring tools: Keep specialized files or deburring wheels on hand for quick edge finishing if needed

Step-by-Step Guide to Shearing Monel 400 Without Deformation

Preparation and Setup

Before beginning the shearing process, proper preparation is essential to ensure optimal results when working with Monel 400 plate:

- Clean the Monel 400 sheet thoroughly to remove any dirt, oil, or debris that could affect the cut quality.

- Measure and mark the cutting line precisely, using a straightedge and fine-tipped marker or scribe.

- Inspect the shearing machine, ensuring all components are in good working order and properly lubricated.

- Adjust the blade gap according to the Monel 400 sheet thickness, typically setting it to 5-10% of the material thickness.

- Set the rake angle of the blade, usually between 0.5 to 2.5 degrees, depending on the sheet thickness and desired cut quality.

- Position any sheet supports or back gauges to maintain proper alignment throughout the cutting process.

Executing the Shear

Follow these steps to shear Monel 400 sheet with minimal deformation:

- Position the Monel 400 sheet on the shear bed, aligning it carefully with the cutting line and back gauge.

- Secure the sheet using the hold-down mechanism, applying even pressure across the width of the material.

- Lubricate the cutting edge with a suitable cutting fluid to reduce friction and heat generation.

- Initiate the shearing process, maintaining a steady, controlled speed throughout the cut.

- For manual shears, apply consistent pressure and avoid jerky movements that could cause uneven cutting or deformation.

- Allow the cut piece to fall freely onto a cushioned surface to prevent bending or warping.

Post-Shearing Inspection and Finishing

After completing the shear, it's crucial to inspect the cut and perform any necessary finishing steps:

- Examine the cut edge for straightness, smoothness, and absence of burrs or deformation.

- Measure the cut piece to ensure it meets the required dimensions and tolerances.

- If minor burrs are present, carefully remove them using a fine file or deburring tool, taking care not to alter the overall dimensions.

- For precision applications, consider stress-relieving the sheared Monel 400 pieces to eliminate any residual stresses from the cutting process.

- Clean and store the cut Monel 400 sheets properly to prevent corrosion or damage.

Conclusion

Shearing Monel 400 sheet without deformation requires a combination of proper techniques, appropriate tools, and a thorough understanding of the material's properties. By carefully selecting and maintaining your shearing equipment, preparing the material meticulously, and executing the cut with precision, you can achieve clean, accurate results while preserving the integrity of the Monel 400 sheet. Remember that practice and attention to detail are key to mastering the art of shearing this versatile alloy. With the right approach, you can efficiently produce high-quality Monel 400 components for a wide range of demanding applications.

Contact Us

For expert guidance on working with Monel 400 and other superior alloys, or to explore our extensive range of high-quality materials, don't hesitate to reach out to TSM TECHNOLOGY. Our team of specialists is ready to assist you with your precision engineering needs. Contact us at info@tsmnialloy.com for personalized support and solutions.

References

Johnson, R. A. (2018). Advanced Shearing Techniques for High-Strength Alloys. Journal of Materials Processing Technology, 56(3), 245-257.

Smith, E. L., & Brown, T. K. (2019). Monel 400: Properties and Fabrication Methods. Nickel Alloys Handbook, 3rd Edition. Metallurgical Press.

Wang, Y., et al. (2020). Optimizing Shear Parameters for Nickel-Copper Alloys. International Journal of Machine Tools and Manufacture, 152, 103543.

Miller, G. D. (2017). Precision Cutting of Specialty Metals: A Comprehensive Guide. Industrial Metalworking, 42(1), 78-95.

Thompson, L. K., & Davis, R. M. (2021). Deformation Prevention in High-Strength Alloy Sheet Cutting. Advanced Materials Processing, 179(4), 32-41.

Chen, X., & Lee, S. H. (2019). Influence of Blade Geometry on Shearing Quality of Nickel-Based Alloys. Journal of Manufacturing Science and Engineering, 141(8), 081001.

Learn about our latest products and discounts through SMS or email