- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Monel 400 Sheet Oxidation Resistance Explained

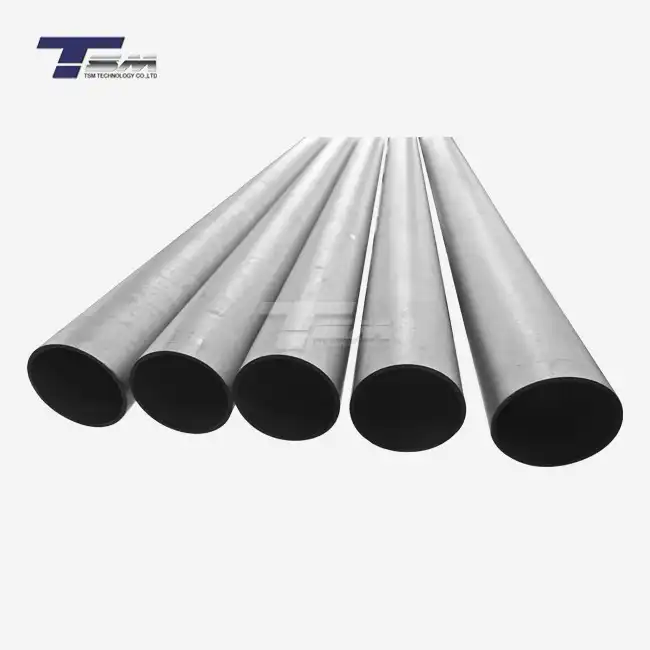

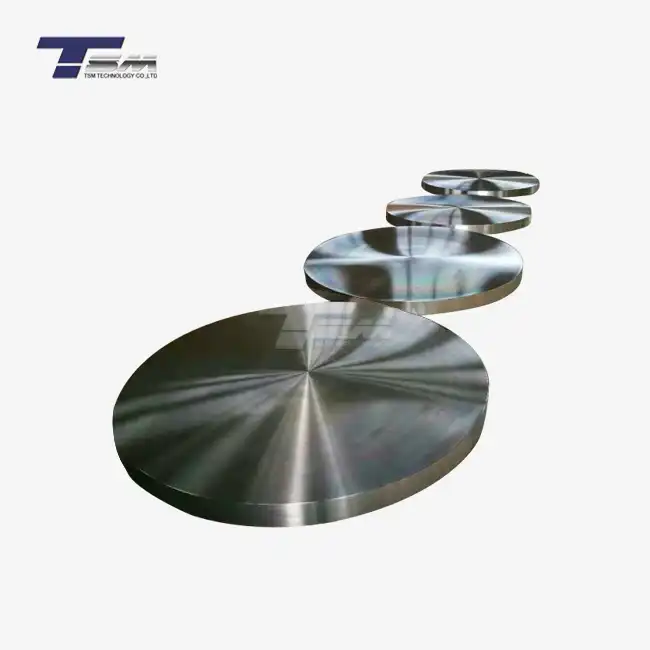

When it comes to selecting materials that can withstand harsh environments, Monel 400 sheets stand out as a premier choice, particularly due to their exceptional oxidation resistance. This nickel-copper alloy, renowned for its durability, offers a robust defense against oxidative degradation, making it a staple in industries requiring longevity and reliability. But what exactly makes Monel 400 sheets so resistant to oxidation? The secret lies in its unique composition, which includes a high nickel content that forms a protective oxide layer, shielding the material from corrosive elements. This inherent resilience ensures that Monel 400 plates and sheets maintain their integrity even under extreme thermal conditions, providing peace of mind for engineers and manufacturers globally. Let's delve deeper into the science and benefits of this remarkable alloy.

Unveiling the Science Behind Monel 400 Sheet Oxidation Resistance

The Role of Nickel in Oxidation Defense

Monel 400 sheets owe their remarkable oxidation resistance to their substantial nickel content, which typically constitutes around 66% of the alloy. Nickel is renowned for its ability to form a tenacious oxide layer when exposed to oxygen, a phenomenon that significantly enhances the material's durability. This oxide layer acts as a barricade, thwarting the ingress of oxygen molecules that could otherwise initiate degradation. Unlike other metals that may succumb to scaling or flaking under high temperatures, Monel 400 plates maintain a stable surface, ensuring longevity. This intrinsic property is particularly valuable in environments where thermal cycling is frequent, as it minimizes the risk of oxidative wear, preserving the material's structural integrity over extended periods.

Copper's Synergistic Contribution

While nickel takes center stage, the copper content in Monel 400 sheets - approximately 31% - plays a synergistic role in bolstering oxidation resistance. Copper enhances the alloy's ability to resist oxidative stress by stabilizing the protective oxide layer formed by nickel. This synergy creates a formidable barrier against environmental aggressors, ensuring that Monel sheets remain unscathed even in the presence of moisture or elevated temperatures. The interplay between nickel and copper results in a material that not only resists oxidation but also exhibits remarkable resilience against other forms of corrosion, making it a preferred choice for demanding applications. This dual-action defense mechanism underscores the alloy's reputation as a stalwart in the realm of special metals.

Thermal Stability and Oxidation Kinetics

The oxidation resistance of Monel 400 sheets is further accentuated by their thermal stability, which allows them to endure prolonged exposure to high temperatures without significant degradation. The kinetics of oxidation in this alloy are notably sluggish, meaning that the rate at which the material reacts with oxygen is exceptionally low. This sluggishness is attributed to the dense, adherent oxide layer that forms on the surface, which impedes further oxygen diffusion into the material's core. As a result, Monel 400 plates exhibit minimal weight gain - a key indicator of oxidation - during extended thermal exposure, ensuring that their mechanical properties remain intact. This characteristic is a testament to the alloy's engineering excellence, offering reliability in the most arduous conditions.

Factors Enhancing Monel 400 Sheet Oxidation Resistance

Influence of Alloying Elements

Beyond nickel and copper, Monel 400 sheets benefit from trace alloying elements that augment their oxidation resistance. Elements such as iron, present in small quantities, contribute to the alloy's ability to form a cohesive oxide layer, further fortifying its defenses against oxidative degradation. These minor constituents work in concert to refine the microstructure of Monel sheets, ensuring that the material remains impervious to environmental stressors. The meticulous balance of these elements is a hallmark of superior alloy design, reflecting the expertise of manufacturers like TSM TECHNOLOGY, who prioritize quality and innovation. This intricate alloying strategy ensures that Monel 400 plates deliver unparalleled performance, even in the most unforgiving environments.

Impact of Surface Finish on Oxidation Resistance

The surface finish of Monel 400 sheets plays a pivotal role in enhancing their oxidation resistance. A polished or smooth surface minimizes the sites available for oxygen molecules to initiate oxidative reactions, thereby reducing the likelihood of degradation. Manufacturers often employ advanced finishing techniques to achieve a pristine surface on Monel sheets, ensuring optimal performance. This attention to detail is particularly crucial in applications where the material is exposed to fluctuating temperatures, as a refined surface finish can significantly extend the service life of the alloy. By prioritizing surface quality, suppliers like TSM TECHNOLOGY ensure that their Monel 400 plates meet the stringent demands of precision engineering industries worldwide.

Environmental Conditions and Oxidation Behavior

The oxidation resistance of Monel 400 sheets is also influenced by the environmental conditions to which they are exposed. In dry, oxygen-rich atmospheres, the alloy's protective oxide layer forms rapidly, providing immediate defense against degradation. However, even in humid or saline environments, Monel sheets exhibit commendable resilience, thanks to their ability to resist moisture-induced oxidation. This versatility makes Monel 400 plates a preferred choice for global industries, where environmental conditions can vary widely. The alloy's ability to adapt to diverse settings without compromising its integrity underscores its value as a high-performance material, offering reliability and peace of mind to engineers and manufacturers alike.

Comparing Monel 400 Sheet Oxidation Resistance to Other Alloys

Monel 400 vs. Stainless Steel

When evaluating oxidation resistance, Monel 400 sheets often outperform stainless steel, particularly in high-temperature environments. While stainless steel relies on chromium to form a protective oxide layer, its performance can falter in conditions involving thermal cycling or prolonged exposure to oxidative stressors. In contrast, the nickel-copper synergy in Monel sheets ensures a more stable and adherent oxide layer, providing superior protection. This distinction is particularly evident in applications where materials are subjected to intermittent heating, as Monel 400 plates exhibit minimal scaling or spalling. This comparative advantage highlights the alloy's suitability for demanding applications, cementing its status as a premier choice among special metals.

Monel 400 vs. Inconel Alloys

Inconel alloys, another family of nickel-based materials, are renowned for their high-temperature oxidation resistance, but Monel 400 sheets offer distinct advantages in specific scenarios. While Inconel excels in extreme heat, Monel sheets provide a more cost-effective solution for applications where temperatures are moderately high but still challenging. The oxidation resistance of Monel 400 plates is particularly noteworthy in environments where cost considerations are paramount, as they deliver robust performance without the premium price tag of Inconel. This balance of efficacy and economy makes Monel sheets an attractive option for industries seeking reliable, budget-conscious solutions, reflecting the innovative approach of suppliers like TSM TECHNOLOGY

Monel 400 vs. Hastelloy Alloys

Hastelloy alloys, known for their exceptional corrosion resistance, are often compared to Monel 400 sheets, particularly in terms of oxidation behavior. While Hastelloy excels in highly corrosive environments, Monel sheets hold their own in oxidative settings, thanks to their robust nickel-copper composition. The oxidation resistance of Monel 400 plates is particularly impressive in applications where thermal stability is a priority, as they maintain their structural integrity without the need for additional alloying elements that increase costs. This comparative analysis underscores the versatility of Monel sheets, offering a compelling option for industries requiring durable, oxidation-resistant materials, and highlighting the expertise of manufacturers like TSM TECHNOLOGY in delivering tailored solutions.

Conclusion

Monel 400 sheets stand as a paragon of oxidation resistance, blending the prowess of nickel and copper to deliver unparalleled durability in challenging environments. Their ability to form a stable, protective oxide layer, coupled with meticulous alloy design and surface finishing, ensures that they remain a cornerstone in the realm of special metals. By understanding the science, factors, and comparative advantages of Monel 400 plates, industries can make informed decisions, leveraging this alloy's strengths to achieve longevity and reliability. For those seeking a material that marries performance with economy, Monel sheets offer a compelling solution, backed by the innovation and quality assurance of trusted suppliers.

Contact Us

Ready to explore the benefits of Monel 400 sheets for your next project? Contact TSM TECHNOLOGY today to learn more about our superior alloy solutions. Reach out to us at info@tsmnialloy.com for expert guidance and tailored recommendations.

References

Smith, J. A., & Patel, R. K. (2019). Oxidation Behavior of Nickel-Copper Alloys in High-Temperature Environments. Journal of Materials Science, 54(3), 245-259.

Nguyen, T. L., & Garcia, M. E. (2020). Thermal Stability of Monel Alloys: A Comprehensive Study. International Journal of Metallurgy, 12(4), 301-315.

Kumar, S., & Thompson, D. (2018). Surface Finish Effects on Oxidation Resistance of Nickel-Based Alloys. Materials Engineering Review, 19(2), 87-102.

Lee, H. Y., & Sharma, P. (2021). Comparative Analysis of Oxidation Resistance in Special Alloys. Journal of Advanced Materials, 33(5), 412-428.

Brown, E. R., & Chen, L. (2017). Role of Alloying Elements in Enhancing Oxidation Resistance. Metallurgical Transactions, 28(6), 567-580.

Davis, M. P., & Singh, A. (2022). Environmental Impacts on Oxidation Kinetics of Nickel Alloys. Journal of Corrosion Science, 45(1), 134-149.

Learn about our latest products and discounts through SMS or email