Understanding Nickel Alloy Round Bars and Their Susceptibility to Oxidation

Composition and Properties of Nickel Alloy Round Bars

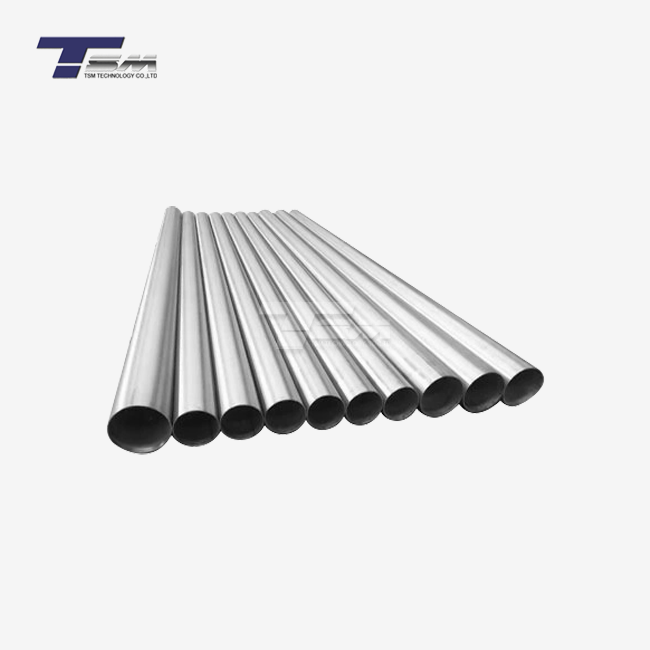

Nickel alloy round bars are high-performance materials known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. These bars are composed of nickel as the primary element, combined with other metals such as chromium, molybdenum, and iron. The specific composition varies depending on the alloy grade, which can include popular types like Inconel, Monel, and Hastelloy.

The unique properties of nickel alloy round bars make them ideal for use in demanding industries such as aerospace, chemical processing, and oil and gas. They offer superior resistance to oxidation, sulfidation, and other forms of corrosion, even in harsh environments. However, despite their inherent resistance, proper storage is crucial to maintain their integrity and prevent oxidation during long-term storage or transportation.

Factors Contributing to Oxidation in Nickel Alloys

While nickel alloys are generally resistant to oxidation, several factors can contribute to the formation of oxide layers on their surface:

- Moisture: Exposure to humid environments can accelerate oxidation processes.

- Temperature: Higher temperatures increase the rate of oxidation reactions.

- Contaminants: Presence of chemicals or pollutants can initiate or accelerate oxidation.

- Surface condition: Scratches or imperfections can provide sites for oxidation to begin.

- Time: Prolonged exposure to air, even in seemingly favorable conditions, can lead to gradual oxidation.

Understanding these factors is essential for implementing effective storage strategies to prevent oxidation and maintain the quality of nickel alloy round bars.

Importance of Proper Storage for Maintaining Material Integrity

Proper storage of nickel alloy round bars is crucial for several reasons:

- Preserving mechanical properties: Oxidation can affect the surface integrity of the bars, potentially impacting their mechanical performance.

- Ensuring quality for end-use applications: Many industries require pristine materials for critical applications, making oxidation prevention essential.

- Cost-effectiveness: Preventing oxidation eliminates the need for additional surface treatments or material replacement.

- Compliance with standards: Many industry standards and specifications require materials to be free from oxidation and surface defects.

By implementing proper storage techniques, manufacturers and users can ensure that nickel alloy round bars maintain their superior properties and meet the stringent requirements of high-performance applications.

Effective Storage Techniques for Nickel Alloy Round Bars

Cleaning and Preparation Before Storage

Before storing nickel alloy round bars, it's crucial to ensure they are properly cleaned and prepared. This initial step sets the foundation for effective long-term storage and oxidation prevention. Here are key considerations:

- Thorough cleaning: Remove any dirt, oils, or contaminants from the surface of the bars using appropriate cleaning agents that won't react with the alloy.

- Drying process: Ensure the bars are completely dry after cleaning to prevent moisture-induced oxidation.

- Surface inspection: Check for any existing signs of oxidation or damage that may require treatment before storage.

- Handling precautions: Use clean gloves and tools to avoid introducing contaminants during the preparation process.

By starting with clean, dry nickel alloy round bars, you significantly reduce the risk of oxidation during storage.

Optimal Environmental Conditions for Storage

Creating and maintaining the right environmental conditions is critical for preventing oxidation in stored nickel alloy round bars. Consider the following factors:

- Temperature control: Store bars in a cool environment, ideally between 15-25°C (59-77°F), to slow down oxidation reactions.

- Humidity management: Maintain relative humidity levels below 50% to minimize moisture exposure.

- Air quality: Ensure storage areas are free from corrosive gases and industrial pollutants that could accelerate oxidation.

- Light exposure: Minimize exposure to direct sunlight or strong artificial light, which can affect surface temperatures.

- Ventilation: Provide adequate air circulation to prevent moisture buildup while avoiding drafts that could introduce contaminants.

Implementing climate control systems and regularly monitoring storage conditions can help maintain an optimal environment for nickel alloy round bars.

Protective Coatings and Packaging Materials

Utilizing appropriate protective coatings and packaging materials adds an extra layer of defense against oxidation for nickel alloy round bars:

- Protective oils: Apply a thin layer of corrosion-inhibiting oil to create a barrier against moisture and air.

- VCI (Volatile Corrosion Inhibitor) products: Use VCI papers, films, or bags that release corrosion-inhibiting molecules to protect the metal surface.

- Desiccants: Include desiccant packets in packaging to absorb any residual moisture.

- Vacuum packaging: Consider vacuum-sealing for long-term storage to eliminate air contact.

- Proper labeling: Clearly label packages with material specifications, date of packaging, and handling instructions.

Choosing the right combination of protective measures based on storage duration and environmental factors can significantly enhance oxidation prevention for nickel alloy round bars.

Monitoring and Maintenance Strategies for Stored Nickel Alloy Round Bars

Regular Inspection Procedures

Implementing a routine inspection schedule is crucial for early detection of potential oxidation issues in stored nickel alloy round bars. Consider the following procedures:

- Visual checks: Regularly examine the surface of the bars for any signs of discoloration, pitting, or other indications of oxidation.

- Scheduled inspections: Establish a calendar for periodic, detailed inspections based on storage duration and environmental conditions.

- Documentation: Maintain detailed records of each inspection, noting any observations or changes in the condition of the bars.

- Sampling: For large quantities, implement a sampling strategy to inspect representative pieces from different storage locations.

- Non-destructive testing: Consider using methods like ultrasonic testing or eddy current inspection for more thorough evaluations when necessary.

Regular inspections allow for prompt identification and addressing of any oxidation issues, helping to maintain the quality of nickel alloy round bars over time.

Addressing Early Signs of Oxidation

When early signs of oxidation are detected, swift action is necessary to prevent further deterioration:

- Immediate isolation: Separate affected bars from the rest to prevent potential spread of oxidation.

- Surface cleaning: Gently clean the affected areas using appropriate methods that won't damage the alloy surface.

- Re-application of protection: After cleaning, reapply protective coatings or oils to restore the protective barrier.

- Environment reassessment: Evaluate the storage conditions that may have contributed to the oxidation and make necessary adjustments.

- Enhanced monitoring: Increase the frequency of inspections for the affected batch and surrounding materials.

Prompt and appropriate response to early signs of oxidation can often salvage the affected nickel alloy round bars and prevent more extensive damage.

Long-term Storage Considerations and Rotation Strategies

For extended storage periods, additional strategies can help maintain the quality of nickel alloy round bars:

- Inventory rotation: Implement a first-in, first-out (FIFO) system to ensure older stock is used before newer materials.

- Periodic repackaging: Consider repackaging bars with fresh protective materials at set intervals for very long-term storage.

- Environmental monitoring: Use data loggers to track temperature and humidity fluctuations in storage areas over time.

- Stress relief considerations: For certain alloys, consider periodic stress relief treatments to prevent internal stress buildup during long-term storage.

- Technology integration: Implement inventory management systems to track storage duration, conditions, and inspection history for each batch of nickel alloy round bars.

By incorporating these long-term strategies, you can ensure that nickel alloy round bars remain in optimal condition, ready for use even after extended storage periods.

Conclusion

Proper storage of nickel alloy round bars is crucial for preventing oxidation and maintaining their superior properties. By implementing effective cleaning procedures, controlling environmental conditions, using appropriate protective coatings and packaging, and maintaining regular inspection routines, you can significantly extend the shelf life of these valuable materials. Remember that prevention is key – addressing potential issues early and adapting storage strategies as needed will help ensure your nickel alloy round bars remain in prime condition, ready for use in critical applications across various industries.

FAQs

What are the main causes of oxidation in nickel alloy round bars?

The primary causes include exposure to moisture, high temperatures, contaminants, and prolonged air contact.

How often should I inspect stored nickel alloy round bars?

Regular inspections should be conducted at least quarterly, with more frequent checks in challenging environments.

Can I use any type of oil to protect nickel alloy round bars?

It's best to use corrosion-inhibiting oils specifically designed for metal protection. Consult with a supplier like TSM Technology for recommendations.

What should I do if I find signs of oxidation on my stored bars?

Isolate the affected bars, clean the surface gently, reapply protective coatings, and reassess storage conditions to prevent further oxidation.

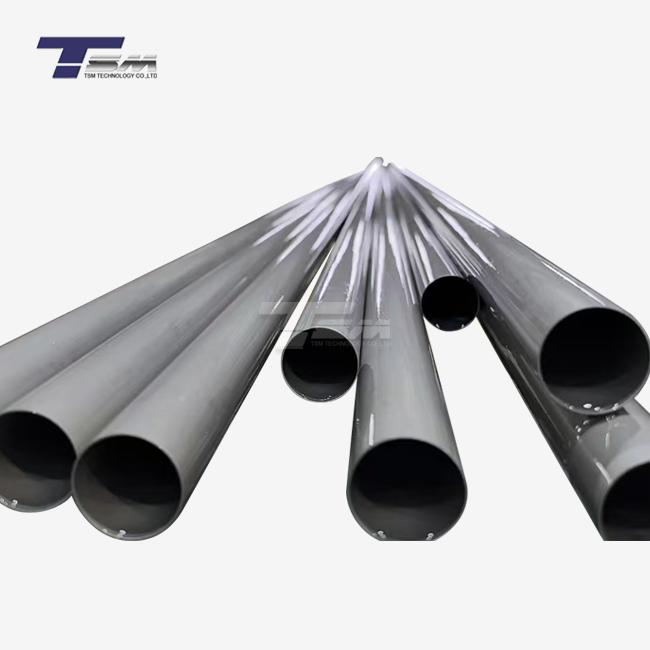

Quality Nickel Alloy Round Bars from TSM TECHNOLOGY

At TSM Technology, we offer premium nickel alloy round bars manufactured to the highest standards. Our products are available in various grades, sizes, and finishes, meeting ASTM, JIS, AISI, GB, DIN, and EN standards. With our advanced manufacturing processes and strict quality control, we ensure superior corrosion resistance and mechanical properties. Trust our 14+ years of expertise for your nickel alloy needs. For inquiries or to discuss your specific requirements, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "Standard Specification for Nickel and Nickel Alloy Bars and Shapes." ASTM B160-21.

Davis, J.R. (2000). "Nickel, Cobalt, and Their Alloys." ASM International.

Revie, R.W., & Uhlig, H.H. (2008). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." John Wiley & Sons.

Special Metals Corporation. (2019). "Inconel Alloy 625 Technical Data Sheet."

Tverberg, J.C. (2010). "Storage and Handling of Nickel Alloys." Materials Performance, 49(2), 56-59.

Woodford, C. (2022). "Nickel: The Metal That Made Stainless Steel." Explain That Stuff.