- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Test the Purity of Nickel 201 Tubes?

Testing the purity of Nickel 201 tubes is crucial for ensuring product quality and performance in various industrial applications. To accurately determine the purity of Nickel 201 tubes, several methods can be employed. These include spectroscopic analysis techniques such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), which provide precise elemental composition data. Additionally, chemical analysis methods like atomic absorption spectroscopy (AAS) and wet chemical analysis can be used to quantify impurities. Physical testing, including hardness measurements and microstructural examination, can also offer insights into the material's purity and overall quality. By combining these testing methods, manufacturers and end-users can verify the purity and integrity of Nickel 201 tubes, ensuring they meet the required specifications for their intended applications.

Spectroscopic Analysis Techniques for Nickel 201 Tube Purity Testing

X-ray Fluorescence (XRF) Analysis

X-ray fluorescence (XRF) analysis is a non-destructive testing method widely used for determining the elemental composition of Nickel 201 tubes. This technique works by bombarding the sample with high-energy X-rays, causing the atoms within the material to emit characteristic fluorescent X-rays. These emitted X-rays are then detected and analyzed to identify and quantify the elements present in the sample.

XRF analysis offers several advantages for testing Nickel 201 tube purity:

- Rapid results: XRF can provide elemental composition data within minutes

- Non-destructive: The sample remains intact after testing

- Minimal sample preparation: Often requires little to no sample preparation

- Detection of trace elements: Can identify and quantify elements present in low concentrations

When using XRF for Nickel 201 tube purity testing, it's essential to calibrate the instrument using certified reference materials to ensure accurate results. The analysis can detect the presence of alloying elements and impurities, allowing for a comprehensive assessment of the material's composition and purity.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a highly sensitive analytical technique used for determining the elemental composition of Nickel 201 tubes with exceptional accuracy. This method involves ionizing the sample using an inductively coupled plasma and then separating and quantifying the ions based on their mass-to-charge ratio using a mass spectrometer.

ICP-MS offers several benefits for Nickel 201 tube purity testing:

- Extremely low detection limits: Can detect elements at parts per trillion (ppt) levels

- Multi-element analysis: Capable of analyzing multiple elements simultaneously

- High precision and accuracy: Provides highly reliable quantitative results

- Wide dynamic range: Can measure both major and trace elements in a single analysis

When preparing Nickel 201 tube samples for ICP-MS analysis, it's crucial to follow proper digestion and dilution procedures to ensure complete dissolution of the material. This method is particularly useful for detecting trace impurities that may affect the performance of Nickel 201 tubes in critical applications.

Optical Emission Spectroscopy (OES)

Optical Emission Spectroscopy (OES) is another valuable technique for assessing the purity of Nickel 201 tubes. This method involves exciting atoms in the sample using an electrical discharge or plasma, causing them to emit light at characteristic wavelengths. The emitted light is then analyzed to determine the elemental composition of the sample.

OES offers several advantages for Nickel 201 tube purity testing:

- Fast analysis: Provides rapid results for multiple elements

- Good sensitivity: Capable of detecting trace elements in the parts per million (ppm) range

- Versatility: Suitable for analyzing both metallic and non-metallic elements

- Minimal sample preparation: Often requires only surface cleaning before analysis

When using OES for Nickel 201 tube purity testing, it's important to ensure proper calibration of the instrument using certified reference materials. This technique is particularly useful for routine quality control and composition verification in manufacturing environments.

Chemical Analysis Methods for Verifying Nickel 201 Tube Purity

Atomic Absorption Spectroscopy (AAS)

Atomic Absorption Spectroscopy (AAS) is a widely used analytical technique for determining the concentration of specific elements in Nickel 201 tubes. This method involves atomizing the sample and measuring the absorption of light at wavelengths characteristic of the elements of interest.

AAS offers several benefits for Nickel 201 tube purity testing:

- High sensitivity: Capable of detecting elements at parts per million (ppm) levels

- Element-specific analysis: Provides accurate results for individual elements

- Relatively simple operation: Requires less complex instrumentation compared to some other techniques

- Cost-effective: Generally lower in cost than more advanced spectroscopic methods

When preparing Nickel 201 tube samples for AAS analysis, it's essential to follow proper digestion procedures to ensure complete dissolution of the material. This method is particularly useful for quantifying specific impurities or alloying elements that may affect the performance of Nickel 201 tubes in various applications.

Wet Chemical Analysis

Wet chemical analysis encompasses a range of traditional analytical techniques that involve chemical reactions to determine the composition of Nickel 201 tubes. These methods often include gravimetric analysis, volumetric analysis, and colorimetric techniques.

Wet chemical analysis offers several advantages for Nickel 201 tube purity testing:

- High accuracy: Can provide highly precise results when performed correctly

- Versatility: Suitable for analyzing a wide range of elements and compounds

- Low equipment costs: Often requires less expensive instrumentation compared to spectroscopic methods

- Complementary to other techniques: Can be used to validate results from other analytical methods

When conducting wet chemical analysis on Nickel 201 tubes, it's crucial to follow standardized procedures and use high-purity reagents to ensure accurate results. These methods can be particularly useful for determining the concentration of specific elements or compounds that may be challenging to analyze using other techniques.

Electrochemical Analysis

Electrochemical analysis techniques can provide valuable insights into the purity and corrosion resistance of Nickel 201 tubes. These methods involve measuring the electrical properties of the material when subjected to controlled potential or current conditions.

Electrochemical analysis offers several benefits for Nickel 201 tube purity testing:

- In-situ analysis: Can be performed directly on the tube surface without extensive sample preparation

- Corrosion behavior assessment: Provides information on the material's resistance to various corrosive environments

- Sensitivity to surface conditions: Can detect surface impurities or contamination that may affect performance

- Non-destructive testing: Many electrochemical techniques do not damage the sample

Common electrochemical techniques used for Nickel 201 tube analysis include potentiodynamic polarization, electrochemical impedance spectroscopy (EIS), and cyclic voltammetry. These methods can provide valuable information about the material's purity, passivation behavior, and overall corrosion resistance, which are critical factors in many industrial applications.

Physical Testing Methods for Assessing Nickel 201 Tube Quality

Hardness Testing

Hardness testing is a crucial physical method for assessing the quality and purity of Nickel 201 tubes. This technique measures the material's resistance to localized plastic deformation, which can be indicative of its overall strength and purity.

Common hardness testing methods for Nickel 201 tubes include:

- Brinell hardness test: Uses a hardened steel or carbide ball to create an indentation

- Rockwell hardness test: Measures the depth of penetration of an indenter under a large load

- Vickers hardness test: Uses a diamond pyramid indenter to create a small indentation

Hardness testing can provide valuable insights into the material's purity and heat treatment condition. Variations in hardness values may indicate the presence of impurities or inconsistencies in the manufacturing process. When conducting hardness tests on Nickel 201 tubes, it's essential to follow standardized procedures and use calibrated equipment to ensure accurate and reproducible results.

Microstructural Examination

Microstructural examination is a powerful technique for assessing the quality and purity of Nickel 201 tubes. This method involves analyzing the material's microscopic structure using various imaging techniques, providing valuable information about grain size, phase distribution, and the presence of impurities or defects.

Common microstructural examination techniques for Nickel 201 tubes include:

- Optical microscopy: Provides high-resolution images of the material's surface structure

- Scanning electron microscopy (SEM): Offers detailed imaging and elemental analysis capabilities

- Transmission electron microscopy (TEM): Allows for examination of the material's internal structure at atomic resolution

Microstructural examination can reveal important information about the purity and quality of Nickel 201 tubes, such as the presence of inclusions, grain boundary segregation, or unexpected phases. Proper sample preparation, including polishing and etching, is crucial for obtaining accurate and meaningful results from microstructural analysis.

Tensile Testing

Tensile testing is a fundamental physical method for evaluating the mechanical properties and quality of Nickel 201 tubes. This technique involves subjecting a sample of the material to a controlled tensile load until failure, providing valuable data on its strength, ductility, and overall performance.

Key parameters measured during tensile testing of the products include:

- Yield strength: The stress at which the material begins to deform plastically

- Ultimate tensile strength: The maximum stress the material can withstand before failure

- Elongation: The extent to which the material stretches before breaking

- Modulus of elasticity: A measure of the material's stiffness

Tensile testing can provide insights into the purity and quality of Nickel 201 tubes by revealing any deviations from expected mechanical properties. Impurities or manufacturing defects may manifest as reduced strength or ductility. When conducting tensile tests on Nickel 201 tubes, it's crucial to follow standardized procedures and use properly calibrated testing equipment to ensure accurate and reliable results.

Conclusion

Testing the purity of Nickel 201 tubes is a multifaceted process that requires a combination of spectroscopic, chemical, and physical testing methods. By employing techniques such as XRF, ICP-MS, AAS, and microstructural examination, manufacturers and end-users can comprehensively assess the composition, quality, and performance of Nickel 201 tubes. These testing methods not only verify the material's purity but also ensure its suitability for critical applications in industries such as aerospace, chemical processing, and energy production. Implementing a rigorous testing protocol helps maintain the high standards expected of Nickel 201 tubes, guaranteeing their reliability and longevity in demanding environments.

FAQs

What is the minimum purity level for Nickel 201 tubes?

Nickel 201 tubes typically have a minimum nickel content of 99.0%.

How often should Nickel 201 tubes be tested for purity?

Testing frequency depends on the application, but it's generally recommended to test each batch or lot during production and periodically during use.

Can purity testing damage Nickel 201 tubes?

Many testing methods, such as XRF and hardness testing, are non-destructive. However, some chemical analyses may require small sample sections.

What are the most common impurities found in Nickel 201 tubes?

Common impurities include carbon, manganese, iron, sulfur, and silicon, though levels are typically very low.

How does purity affect the performance of Nickel 201 tubes?

Higher purity generally results in better corrosion resistance, mechanical properties, and overall performance in demanding applications.

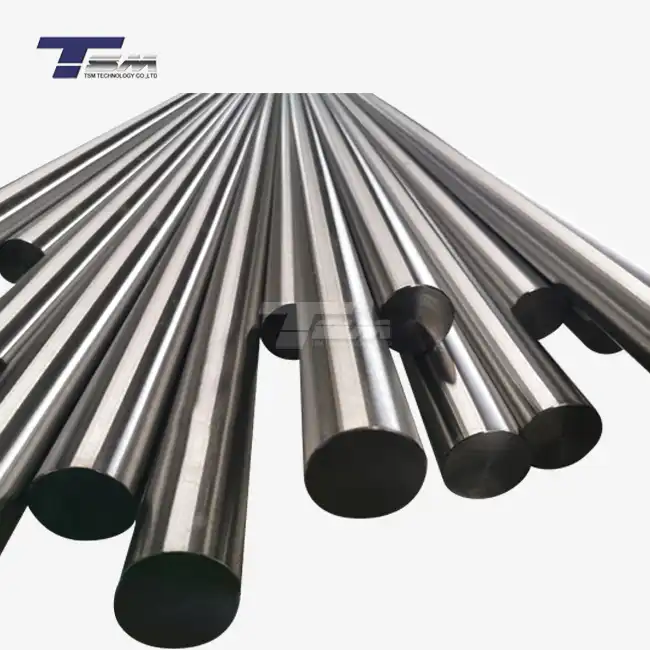

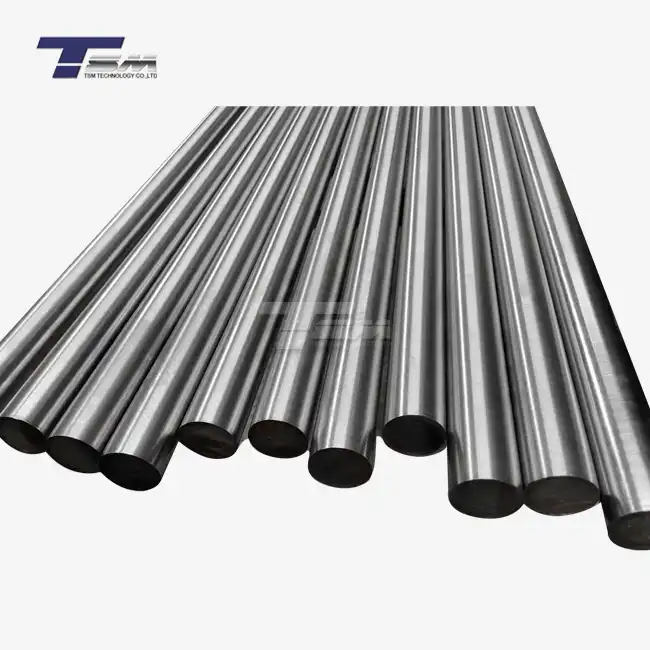

Get High-Purity Nickel 201 Tubes from TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-quality Nickel 201 tubes that meet the most stringent purity requirements. Our state-of-the-art testing facilities and rigorous quality control processes ensure that every tube we manufacture meets or exceeds industry standards. With our expertise in nickel alloys and commitment to customer satisfaction, we're your ideal partner for all your Nickel 201 tube needs. Contact us today at info@tsmnialloy.com to learn more about our premium Nickel 201 tubes and how we can support your projects with our superior alloy solutions.

References

ASTM International. "Standard Specification for Nickel Seamless Pipe and Tube." ASTM B161-20.

ASM International. "Handbook of Materials Characterization Techniques for Metals and Alloys." 2019.

Lai, G.Y. "High-Temperature Corrosion and Materials Applications." ASM International, 2007.

Special Metals Corporation. "Nickel 201 Technical Data Sheet." 2018.

NACE International. "Corrosion Testing of Nickel-Base Alloys." NACE Standard TM0169-2000.

Shoemaker, L.E. "Alloys for High Temperature Applications: Nickel-Based Alloys." Elsevier, Encyclopedia of Materials: Science and Technology, 2001.

Learn about our latest products and discounts through SMS or email