Understanding Hastelloy C276 and Its Properties

Composition and Characteristics of Hastelloy C276

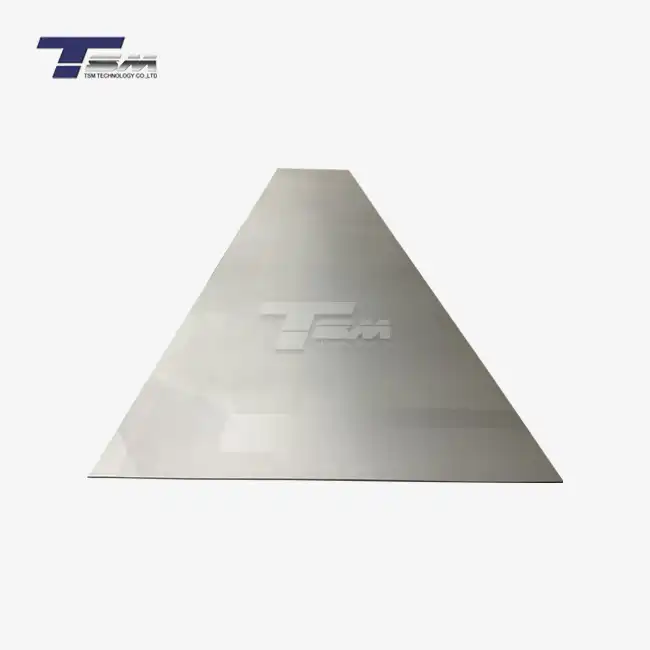

Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its outstanding corrosion resistance. Its unique composition includes approximately 57% nickel, 16% molybdenum, 16% chromium, and smaller amounts of tungsten, iron, and other elements. This carefully balanced formulation gives Hastelloy C276 seamless pipes their remarkable resistance to a wide range of aggressive chemicals, including hydrochloric acid, sulfuric acid, and chlorine-containing media.

The alloy's exceptional pitting resistance and stress-corrosion cracking resistance make it an ideal choice for applications in chemical processing, pollution control equipment, and offshore oil and gas production. Hastelloy C276 tubing also exhibits excellent mechanical properties, maintaining its strength and ductility across a broad temperature range, from cryogenic conditions to elevated temperatures exceeding 1000°C (1832°F).

Applications of Hastelloy C276 Tubes

Hastelloy C276 tubes find extensive use in industries where corrosion resistance and high-temperature strength are paramount. Some key applications include:

- Chemical processing equipment

- Flue gas desulfurization systems

- Nuclear waste treatment facilities

- Pharmaceutical manufacturing

- Offshore oil and gas production platforms

- Heat exchangers in aggressive environments

The versatility of Hastelloy C276 seamless pipes makes them indispensable in scenarios where failure due to corrosion or high-temperature degradation is not an option. Their ability to withstand extreme conditions while maintaining structural integrity ensures long-term reliability and safety in critical industrial processes.

Manufacturing Process of Hastelloy C276 Tubing

The production of Hastelloy C276 tubing involves a sophisticated manufacturing process that ensures the alloy's superior properties are maintained throughout. The process typically includes:

- Melting and alloying: Precise amounts of constituent elements are melted in a controlled environment to create the Hastelloy C276 composition.

- Ingot casting: The molten alloy is cast into ingots or continuous cast into billets.

- Hot working: The ingots or billets are hot-worked through processes like forging or extrusion to create the initial tube shape.

- Cold drawing or pilgering: The tubes are further refined through cold working processes to achieve the desired dimensions and mechanical properties.

- Heat treatment: Carefully controlled heat treatment processes are applied to optimize the alloy's microstructure and properties.

- Surface finishing: The tubes undergo surface treatments to enhance corrosion resistance and achieve the required surface quality.

Throughout this manufacturing process, stringent quality control measures are implemented to ensure that the Hastelloy C276 tubes meet the highest standards of performance and reliability.

The Importance of Hydrostatic Testing in Quality Assurance

Principles of Hydrostatic Testing

Hydrostatic testing is a fundamental quality assurance technique used to verify the structural integrity and leak-tightness of pressure vessels, pipes, and tubes. For Hastelloy C276 tubing, this test is particularly crucial due to the critical nature of its applications. The principles underlying hydrostatic testing are based on Pascal's law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

During the test, the Hastelloy C276 tube is filled with water or another incompressible fluid and pressurized to a predetermined level, typically 1.5 times the design pressure. This pressure is maintained for a specified period, usually several hours, while inspectors monitor for any signs of leakage, deformation, or failure. The test pressure creates stress in the tube wall that is higher than normal operating conditions, effectively revealing any weaknesses or defects that might not be apparent under standard pressures.

Benefits of Hydrostatic Testing for Hastelloy C276 Seamless Pipes

Hydrostatic testing offers several critical benefits for Hastelloy C276 seamless pipes:

- Verification of pressure-holding capacity: Ensures that the tubes can withstand operational pressures without failure.

- Detection of manufacturing defects: Identifies issues such as incomplete welds, material flaws, or wall thickness inconsistencies.

- Quality assurance: Provides confidence in the reliability and safety of the Hastelloy C276 tubing for end-users.

- Compliance with industry standards: Meets regulatory requirements and international standards for pressure equipment.

- Prevention of in-service failures: Helps avoid costly and potentially dangerous failures during operation.

- Validation of design calculations: Confirms that theoretical design calculations align with actual performance.

These benefits are particularly significant for Hastelloy C276 tubes used in high-stakes applications where failure could lead to catastrophic consequences, such as in chemical processing plants or offshore oil platforms.

Hydrostatic Testing Standards and Regulations

Hydrostatic testing of Hastelloy C276 tubes is governed by various international standards and regulations to ensure consistency and reliability across industries. Some of the key standards include:

- ASME Boiler and Pressure Vessel Code (BPVC): Provides comprehensive guidelines for pressure vessel testing, including hydrostatic tests.

- ASTM E1003: Standard Test Method for Hydrostatic Leak Testing.

- API 570: Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems.

- ISO 1402: Rubber and plastics hoses and hose assemblies - Hydrostatic testing.

These standards specify test pressures, hold times, acceptance criteria, and documentation requirements. Compliance with these standards ensures that Hastelloy C276 tubing meets the highest quality and safety benchmarks, instilling confidence in their performance across diverse applications.

Hydrostatic Testing Procedure for Hastelloy C276 Tubes

Preparation and Setup

The hydrostatic testing procedure for Hastelloy C276 tubes begins with meticulous preparation and setup. This phase is critical to ensure accurate and reliable test results. The steps typically include:

- Visual inspection: Examine the Hastelloy C276 seamless pipes for any visible defects or damage.

- Cleaning: Thoroughly clean the tubes to remove any debris or contaminants that could interfere with the test.

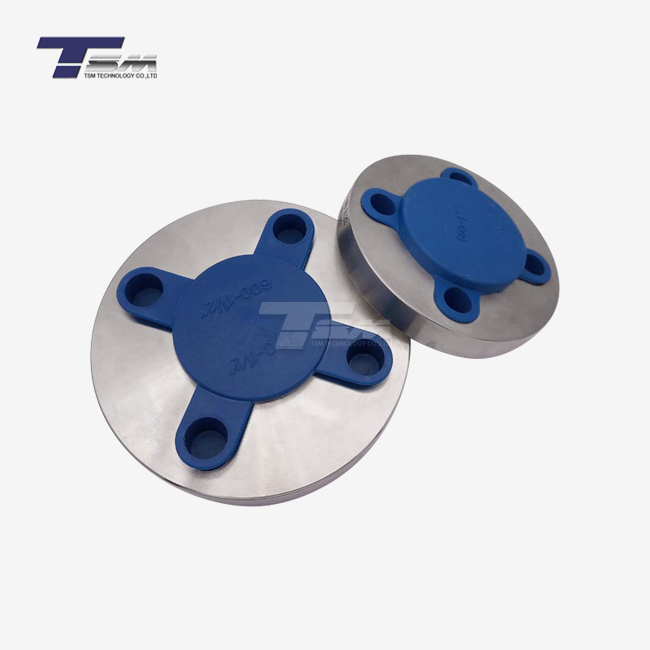

- End-capping: Seal the tube ends with appropriate fittings or caps designed to withstand the test pressure.

- Instrumentation setup: Install pressure gauges, temperature sensors, and other monitoring equipment.

- Venting: Ensure proper venting to remove all air from the system, as air pockets can affect test accuracy.

- Safety measures: Implement safety protocols, including establishing a safe perimeter around the test area.

Proper preparation minimizes the risk of false results and ensures the safety of personnel conducting the test. For Hastelloy C276 tubing, which often handles critical fluids in extreme environments, this preparatory phase is particularly important to validate its exceptional corrosion resistance and structural integrity.

Test Execution and Monitoring

The execution of the hydrostatic test on Hastelloy C276 tubes involves several key steps:

- Filling: Slowly fill the tube with the test fluid, usually water, ensuring complete air removal.

- Pressurization: Gradually increase the pressure to the specified test level, typically 1.5 times the design pressure for Hastelloy C276 seamless pipes.

- Hold period: Maintain the test pressure for the prescribed duration, often several hours.

- Monitoring: Continuously observe pressure gauges, check for leaks, and monitor for any signs of deformation or failure.

- Data recording: Log pressure readings, temperature, and any observations at regular intervals.

- Depressurization: Slowly reduce pressure back to atmospheric levels after the hold period.

Throughout the test, technicians closely monitor the Hastelloy C276 tubing for any indications of leakage, pressure drops, or structural changes. The alloy's high strength and corrosion resistance should allow it to maintain its integrity even under these elevated test pressures.

Result Analysis and Documentation

After completing the hydrostatic test, a thorough analysis of the results is crucial:

- Pressure stability: Evaluate whether the Hastelloy C276 tube maintained the test pressure without significant drops.

- Visual inspection: Conduct a post-test visual examination for any signs of deformation or leakage.

- Data analysis: Review recorded data to ensure compliance with test parameters and identify any anomalies.

- Comparison with standards: Verify that results meet or exceed the requirements set by relevant industry standards.

- Documentation: Prepare comprehensive test reports detailing all aspects of the hydrostatic test.

For Hastelloy C276 seamless pipes, successful completion of hydrostatic testing confirms their ability to withstand high pressures in corrosive environments. This documentation becomes a critical part of the quality assurance process, providing traceability and confidence in the product's performance capabilities.

Conclusion

Hydrostatic testing is an indispensable quality assurance measure for Hastelloy C276 tubes, validating their exceptional pressure-holding capacity and structural integrity. This rigorous process ensures that Hastelloy C276 seamless pipes and tubing meet the stringent requirements of their demanding applications in corrosive and high-pressure environments. By subjecting these critical components to pressures exceeding operational levels, manufacturers can confidently deliver products that uphold the highest standards of safety and reliability. As industries continue to push the boundaries of material performance, the role of comprehensive testing procedures like hydrostatic testing becomes increasingly vital in maintaining the reputation and trustworthiness of superior alloy products.

Contact Us

For more information about our Hastelloy C276 tubes and our rigorous quality assurance processes, please don't hesitate to reach out. Contact TSM TECHNOLOGY today at info@tsmnialloy.com to discuss how our high-quality alloy products can meet your specific needs and enhance your industrial applications.