Understanding Hastelloy C276 Tube Specifications

Composition and Properties of Hastelloy C276

Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its exceptional resistance to corrosion and oxidation. This versatile material exhibits remarkable strength and durability in extreme environments, making it an ideal choice for critical applications. The unique composition of Hastelloy C276 includes approximately 57% nickel, 16% chromium, 16% molybdenum, and small amounts of tungsten and manganese. This carefully balanced formulation contributes to its superior resistance to pitting, crevice corrosion, and stress corrosion cracking.

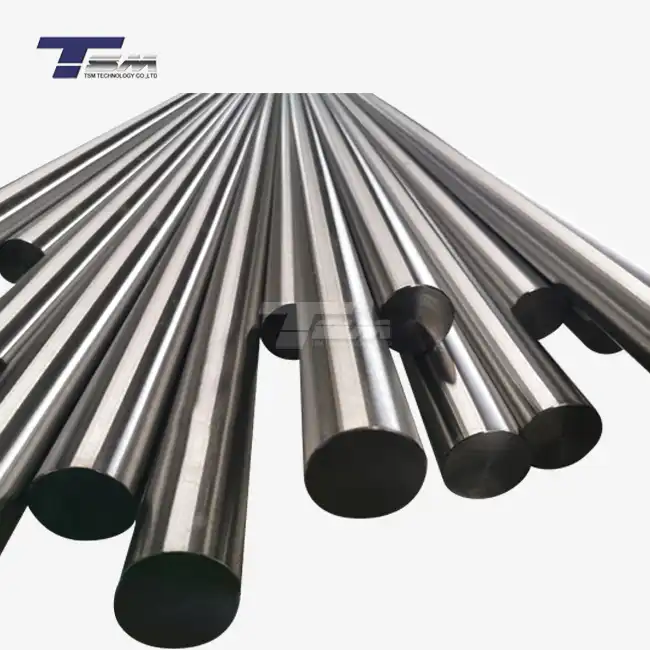

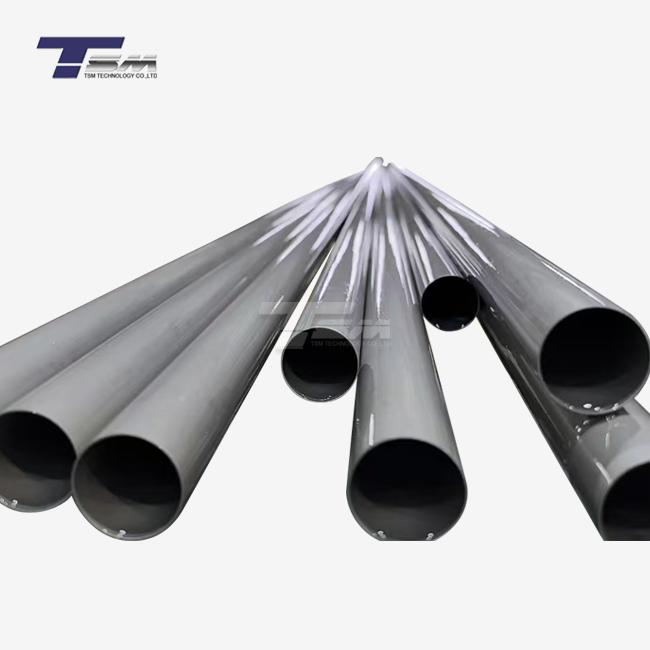

Standard Dimensions for Hastelloy C276 Seamless Pipes

Hastelloy C276 seamless pipes are manufactured to meet specific dimensional requirements. Common outside diameter ranges typically span from 1/8 inch to 24 inches, with wall thicknesses varying based on the intended application. These pipes are often produced in accordance with ASTM B622 or ASME SB622 standards, which define the acceptable tolerances for dimensions, straightness, and surface finish. It's crucial to note that custom sizes can be fabricated to meet unique project specifications, allowing for flexibility in design and implementation.

Tolerances and Allowances in Hastelloy C276 Tubing

Tolerances for Hastelloy C276 tubing are meticulously defined to ensure consistency and reliability. For instance, the outside diameter tolerance for seamless tubes may range from ±0.005 inches for smaller diameters to ±0.031 inches for larger sizes. Wall thickness tolerances are equally stringent, often specified as a percentage of the nominal thickness. These precise allowances are critical for maintaining the structural integrity and performance of Hastelloy C276 components in high-stress environments.

Dimensional Check Procedures for Hastelloy C276 Tubes

Measurement Tools and Techniques

Accurate dimensional checks of Hastelloy C276 tubes require specialized measurement tools and techniques. Precision instruments such as micrometers, calipers, and bore gauges are essential for obtaining reliable measurements. For more advanced assessments, coordinate measuring machines (CMMs) and optical comparators may be employed to verify complex geometries and surface profiles. Ultrasonic testing is often utilized to measure wall thickness with high precision, particularly for tubes with limited access to internal surfaces.

Critical Dimensions to Verify

When conducting dimensional checks on Hastelloy C276 tubing, several critical dimensions must be verified. These include:

- Outside Diameter (OD): Measured at multiple points along the tube's length to ensure consistency.

- Inside Diameter (ID): Crucial for flow characteristics and fitting compatibility.

- Wall Thickness: Vital for pressure ratings and structural integrity.

- Length: Important for proper installation and system design.

- Straightness: Ensures proper alignment and reduces stress concentrations.

- Ovality: Measures the tube's roundness, which is critical for sealing and connection integrity.

Frequency and Sampling Methods

The frequency of dimensional checks and sampling methods for Hastelloy C276 tubes depends on various factors, including production volume, application criticality, and customer requirements. Typically, a statistically significant sample size is selected from each production lot for comprehensive dimensional verification. Continuous monitoring systems may be implemented for high-volume production lines to ensure real-time quality control. Additionally, critical components often undergo 100% inspection to guarantee dimensional accuracy and consistency across the entire production run.

Quality Assurance and Certification for Hastelloy C276 Tube Dimensions

Industry Standards and Specifications

Hastelloy C276 tubes are manufactured and inspected by stringent industry standards and specifications. Key standards include ASTM B619 for seamless nickel and nickel-alloy condenser and heat-exchanger tubes, and ASTM B626 for welded nickel and nickel-cobalt alloy tubes. These standards define the acceptable ranges for chemical composition, mechanical properties, and dimensional tolerances. Compliance with these specifications ensures that Hastelloy C276 tubing meets the performance requirements for diverse industrial applications, from chemical processing to offshore oil and gas extraction.

Documentation and Traceability

Comprehensive documentation and traceability are paramount in the quality assurance process for Hastelloy C276 tubes. Each production lot is accompanied by detailed certification packages that include:

- Material Test Reports (MTRs) documenting chemical composition and mechanical properties

- Dimensional inspection reports with actual measurements

- Non-destructive testing results, such as ultrasonic or eddy current examinations

- Heat treatment records, when applicable

This documentation ensures full traceability from raw material to finished product, enabling end-users to verify the conformity of Hastelloy C276 tubing to project specifications and regulatory requirements.

Third-Party Verification and Audits

To further enhance quality assurance, third-party verification and audits play a crucial role in validating the dimensional accuracy of Hastelloy C276 tubes. Independent inspection agencies may be engaged to conduct dimensional checks, witness testing procedures, and review quality control processes. These impartial assessments provide additional confidence in the conformity of Hastelloy C276 tubing to specified standards. Regular audits of manufacturing facilities by certification bodies ensure ongoing compliance with quality management systems, such as ISO 9001, reinforcing the commitment to dimensional precision and product reliability.

Conclusion

Dimensional check standards for Hastelloy C276 tubes are indispensable in ensuring the quality, reliability, and performance of these critical components. By adhering to rigorous specifications, employing precise measurement techniques, and implementing comprehensive quality assurance processes, manufacturers can deliver Hastelloy C276 tubing that meets the exacting demands of various industries. The meticulous attention to dimensional accuracy not only guarantees the structural integrity of the tubes but also contributes to the overall efficiency and safety of the systems in which they are installed. As industrial applications continue to evolve, the importance of maintaining strict dimensional standards for Hastelloy C276 tubes remains paramount in driving innovation and reliability in corrosion-resistant alloy technologies.

Contact Us

For more information about our high-quality Hastelloy C276 tubes and our commitment to dimensional precision, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right Hastelloy C276 tubing solutions for your specific application needs.