Understanding Monel 400 Properties and Machining Challenges

Composition and Characteristics of Monel 400

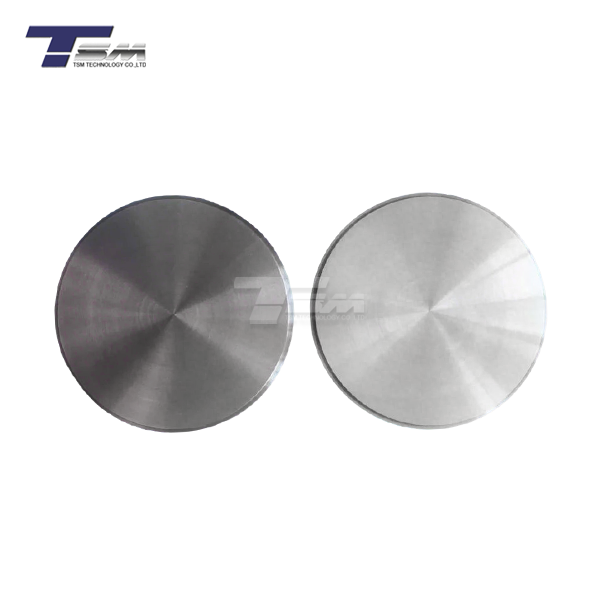

Monel 400 is a nickel-copper alloy renowned for its exceptional corrosion resistance and strength. Comprising approximately 67% nickel and 31% copper, with small amounts of iron and manganese, this alloy exhibits unique properties that make it suitable for various applications in marine, chemical processing, and aerospace industries. The high nickel content contributes to its excellent resistance to saltwater corrosion, while the copper enhances its workability and thermal conductivity.

Mechanical Properties Affecting Machinability

When working with Monel 400 round bar, machinists must consider its specific mechanical properties that influence the machining process. The alloy's relatively high tensile strength (70-85 ksi) and yield strength (25-50 ksi) can lead to increased cutting forces during machining. Additionally, Monel 400's work-hardening tendency can result in built-up edge formation on cutting tools, potentially compromising surface finish quality if not properly managed.

Common Surface Finish Issues in Monel 400 Machining

Machining Monel bar can present several challenges that impact surface finish quality. Some common issues include:

- Galling and smearing due to the material's ductility

- Formation of burrs and rough edges

- Work hardening leading to surface irregularities

- Tool wear resulting in poor surface texture

- Chatter marks caused by vibration during cutting

Addressing these challenges requires a comprehensive approach that considers tooling, cutting parameters, and machining strategies tailored to Monel 400's unique properties.

Optimizing Cutting Tools and Parameters for Enhanced Surface Finish

Selecting the Right Cutting Tool Materials

Choosing appropriate cutting tool materials is crucial for achieving a superior surface finish on Monel 400 bar. High-speed steel (HSS) tools can be used for low-speed operations, but carbide tools are generally preferred for their superior wear resistance and ability to maintain sharp cutting edges. For high-speed machining, ceramic or cubic boron nitride (CBN) inserts may offer improved performance and longer tool life.

Tool Geometry Considerations

Optimizing tool geometry can significantly impact the surface finish of Monel round bar. Consider the following recommendations:

- Use positive rake angles (5° to 15°) to reduce cutting forces and minimize work hardening

- Implement large relief angles (10° to 15°) to prevent rubbing and improve chip evacuation

- Employ sharp cutting edges with a small nose radius to minimize cutting forces and improve surface finish

- Consider chip breaker geometries to control chip formation and prevent surface damage

Cutting Parameter Optimization

Fine-tuning cutting parameters is essential for achieving an excellent surface finish on Monel 400 bar. Consider the following guidelines:

- Cutting speed: Use moderate to high cutting speeds (100-300 m/min) to reduce built-up edge formation

- Feed rate: Employ low to moderate feed rates (0.1-0.3 mm/rev) to minimize surface roughness

- Depth of cut: Maintain shallow depths of cut (0.5-2 mm) to reduce cutting forces and improve surface quality

- Coolant: Use abundant, high-pressure coolant to improve chip evacuation and reduce heat generation

By carefully balancing these parameters, machinists can optimize the cutting process for improved surface finish on Monel 400 round bar.

Advanced Machining Techniques for Superior Surface Finish

High-Speed Machining (HSM) Strategies

Implementing high-speed machining techniques can lead to significant improvements in surface finish quality when working with Monel bar. HSM involves using higher cutting speeds and feed rates while maintaining lower depths of cut. This approach can result in reduced cutting forces, improved chip formation, and enhanced surface finish. When applying HSM to Monel 400, consider the following strategies:

- Utilize rigid machine tools with high spindle speeds and precise motion control

- Employ balanced tooling systems to minimize vibration at high speeds

- Implement trochoidal milling paths to maintain consistent chip loads and reduce tool wear

- Use climb milling whenever possible to improve surface finish and extend tool life

Cryogenic Machining for Improved Surface Quality

Cryogenic machining is an innovative technique that can significantly enhance the surface finish of Monel 400 round bar. This process involves using liquid nitrogen or carbon dioxide as a coolant, which rapidly reduces the temperature at the cutting zone. The benefits of cryogenic machining for Monel 400 include:

- Reduced work hardening, leading to improved surface finish

- Decreased tool wear, resulting in more consistent surface quality

- Improved chip breakability and evacuation

- Enhanced dimensional accuracy due to reduced thermal expansion

When implementing cryogenic machining, it's essential to use specialized equipment and carefully control the cryogenic fluid delivery to achieve optimal results.

Vibration-Assisted Machining (VAM) for Enhanced Surface Finish

Vibration-assisted machining is another advanced technique that can improve the surface finish of Monel bar. VAM involves superimposing high-frequency, low-amplitude vibrations onto the cutting tool or workpiece during the machining process. This approach offers several advantages for machining Monel 400:

- Reduced cutting forces, leading to improved surface quality

- Enhanced chip breakage and evacuation

- Decreased tool wear and extended tool life

- Improved machining of intricate features and thin-walled sections

When implementing VAM for Monel 400 machining, it's crucial to carefully tune the vibration parameters to achieve the desired surface finish without compromising dimensional accuracy or tool life.

Conclusion

Improving the surface finish of Monel 400 bar during machining requires a multifaceted approach that combines proper tool selection, optimized cutting parameters, and advanced machining techniques. By understanding the unique properties of Monel 400 and implementing strategies such as high-speed machining, cryogenic cooling, and vibration-assisted machining, manufacturers can achieve superior surface quality while maintaining productivity. As the demand for high-performance components made from Monel 400 continues to grow, mastering these techniques will be crucial for meeting increasingly stringent quality requirements and maintaining a competitive edge in the precision engineering industry.

Contact Us

For more information on Monel 400 bar and other superior nickel alloys, or to discuss your specific machining needs, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in achieving the highest quality surface finish for your Monel 400 components.