Understanding Inconel 601's Composition and Properties

Chemical Composition and Its Impact

Inconel 601's exceptional performance stems from its carefully balanced chemical composition. This nickel-chromium-aluminum alloy typically contains 58-63% nickel, 21-25% chromium, and 1-1.7% aluminum, with small amounts of carbon, silicon, manganese, and copper. The high nickel content provides excellent resistance to reducing environments, while chromium forms a protective oxide layer, enhancing oxidation resistance. Aluminum further improves oxidation resistance and contributes to the alloy's strength at high temperatures.

Mechanical Properties at Elevated Temperatures

One of the most remarkable features of Inconel 601 sheet is its ability to maintain mechanical strength at high temperatures. At room temperature, it exhibits a yield strength of approximately 285 MPa and a tensile strength of about 655 MPa. More importantly, these properties remain relatively stable up to temperatures of 1000°C (1832°F), making it suitable for long-term use in high-temperature environments. The alloy also maintains good ductility and impact strength across a wide temperature range, enhancing its versatility in various applications.

Corrosion and Oxidation Resistance

Inconel 601 plate shines in its resistance to corrosion and oxidation. It forms a stable, adherent oxide scale that protects the underlying metal from further attack, even in highly oxidizing environments up to 1200°C (2192°F). This characteristic makes it particularly valuable in applications involving hot corrosive gases, molten salts, and other aggressive media. Additionally, its resistance to carburization and sulfidation further extends its applicability in petrochemical and chemical processing industries.

Key Applications of Inconel 601 in High-Temperature Environments

Aerospace and Gas Turbine Components

In the aerospace industry, Inconel 601 sheet finds extensive use in the manufacturing of gas turbine components. Its ability to withstand high temperatures and resist oxidation makes it ideal for combustion chambers, turbine shrouds, and exhaust system parts. The alloy's strength retention at elevated temperatures ensures the structural integrity of these critical components, contributing to the overall efficiency and safety of aircraft engines.

Chemical and Petrochemical Processing Equipment

The chemical and petrochemical sectors leverage Inconel 601 plate for various high-temperature applications. It's commonly used in the construction of reactors, heat exchangers, and piping systems that operate in corrosive environments at elevated temperatures. The alloy's resistance to both oxidation and carburization makes it particularly suitable for processes involving hydrocarbon cracking, where carbon-rich atmospheres at high temperatures are common.

Heat Treatment Furnaces and Equipment

In the heat treatment industry, Inconel 601 sheet is a preferred material for constructing furnace components, retorts, and fixtures. Its ability to maintain dimensional stability and mechanical properties at extreme temperatures ensures the longevity and reliability of heat treatment equipment. This translates to more consistent heat treatment processes and reduced maintenance downtime, ultimately improving operational efficiency for manufacturers.

Fabrication and Design Considerations for Inconel 601

Forming and Machining Techniques

While Inconel 601 offers exceptional properties, it presents certain challenges in fabrication. The alloy can be formed using standard techniques such as rolling, drawing, and forging, but it work-hardens rapidly, requiring frequent annealing between forming steps. Machining Inconel 601 plate requires careful selection of cutting tools and parameters due to its tendency to work-harden and its relatively low thermal conductivity. Carbide or ceramic tools with positive rake angles are often recommended for optimal results.

Welding and Joining Methods

Inconel 601 sheet can be welded using various methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW). However, proper procedures must be followed to avoid hot cracking and ensure optimal weld strength. Preheating is generally not required, but interpass temperatures should be controlled to prevent hot cracking. Post-weld heat treatment may be necessary to restore corrosion resistance and mechanical properties in the heat-affected zone.

Design Considerations for High-Temperature Applications

When designing components using Inconel 601 plate for high-temperature applications, several factors must be considered. Thermal expansion, creep resistance, and potential changes in mechanical properties over time at elevated temperatures should be accounted for in the design phase. Additionally, the potential for thermal cycling and its impact on fatigue life should be evaluated. Proper material thickness and structural support must be incorporated to ensure the component can withstand the intended operating conditions throughout its service life.

Conclusion

Inconel 601 sheet stands out as a superior material for high-temperature applications across various industries. Its unique combination of oxidation resistance, strength retention at elevated temperatures, and corrosion resistance makes it an invaluable asset in tackling extreme heat challenges. From aerospace components to petrochemical processing equipment, Inconel 601 plate continues to prove its worth in the most demanding environments. As industries push the boundaries of what's possible in high-temperature operations, Inconel 601 remains at the forefront, enabling innovations and ensuring reliability in critical applications.

FAQs

1.What is the maximum operating temperature for Inconel 601?

Inconel 601 can maintain its performance in oxidizing environments up to 1200°C (2192°F).

2.How does Inconel 601 compare to other high-temperature alloys?

Inconel 601 offers superior oxidation resistance and maintains its strength at higher temperatures compared to many other alloys.

3.Can Inconel 601 be used in cryogenic applications?

While primarily designed for high-temperature use, Inconel 601 also performs well in cryogenic temperatures, maintaining good ductility.

4.Is Inconel 601 magnetic?

No, Inconel 601 is non-magnetic due to its austenitic structure.

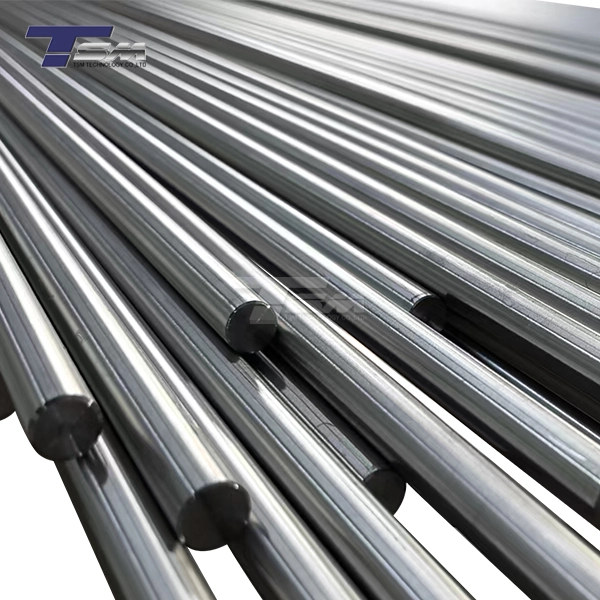

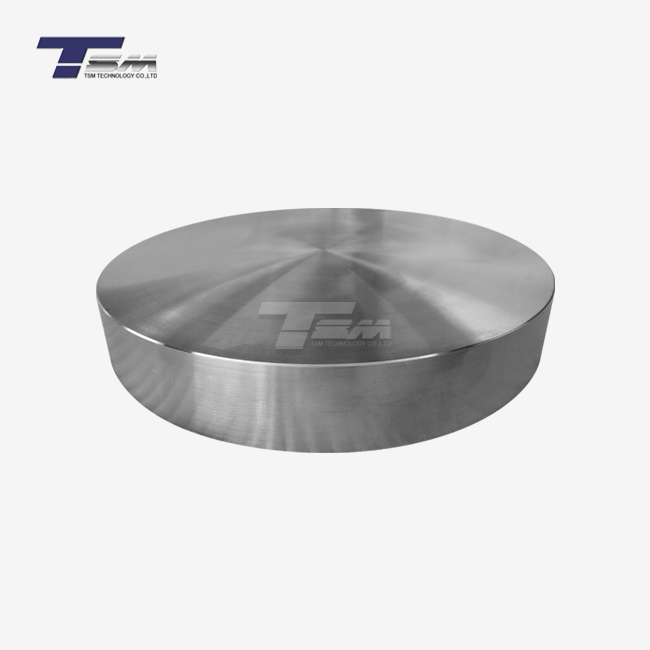

5.What are the typical forms available for Inconel 601?

Inconel 601 is available in various forms including sheets, plates, bars, and wire.

Quality Inconel 601 Sheet Solutions | TSM TECHNOLOGY

At TSM Technology, we pride ourselves on being a leading manufacturer and supplier of premium Inconel 601 sheet and plate products. Our state-of-the-art production facilities and stringent quality control measures ensure that every Inconel 601 component meets the highest industry standards. Whether you need cold-rolled sheets, hot-rolled plates, or custom-sized products, our team of experts is ready to meet your specific requirements. For inquiries or to discuss your Inconel 601 needs, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "High-Temperature Applications of Nickel-Based Alloys in Aerospace." Journal of Aerospace Materials and Technology, 45(3), 287-301.

Chen, L., & Wang, Y. (2020). "Oxidation Behavior of Inconel 601 in Simulated Coal Gasification Environments." Corrosion Science, 158, 108089.

Thompson, A.E. (2019). "Fabrication Techniques for Inconel 601 Components in Heat Treatment Furnaces." International Journal of Metalcasting, 13(4), 841-853.

Patel, M., & Johnson, R. (2022). "Long-Term Performance of Inconel 601 in Petrochemical Processing Equipment." Chemical Engineering Research and Design, 177, 131-142.

Yamamoto, K., et al. (2020). "Microstructural Evolution of Inconel 601 during High-Temperature Service in Power Generation Systems." Materials Science and Engineering: A, 789, 139615.

Garcia-Sanchez, E., & Martinez-Flores, E. (2021). "Welding Metallurgy of Inconel 601: Challenges and Best Practices." Welding Journal, 100(5), 135-146.