Exceptional Properties of Inconel 601 Sheet for Power Generation

High-Temperature Resistance

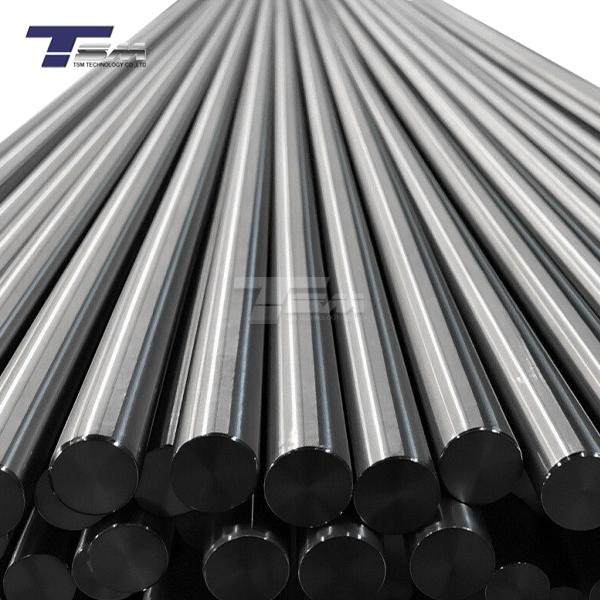

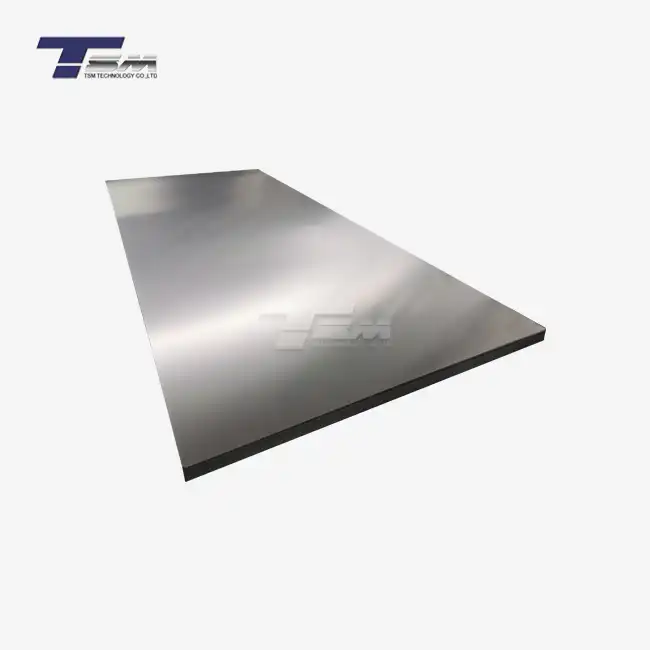

Inconel 601 sheet exhibits remarkable strength and stability at elevated temperatures, making it ideal for power generation applications. This alloy maintains its mechanical properties up to 1200°C, ensuring reliable performance in extreme conditions. The high-temperature resistance of Inconel 601 enables the design of more efficient power systems, as components can withstand higher operating temperatures without compromising their structural integrity.

Oxidation Resistance

One of the standout features of Inconel 601 is its exceptional oxidation resistance. In power generation environments where oxidizing atmospheres are common, this alloy forms a protective oxide layer that prevents further degradation. This self-healing property significantly extends the lifespan of components, reducing the need for frequent replacements and minimizing downtime in power plants.

Corrosion Resistance

Inconel 601 plate demonstrates excellent resistance to various corrosive media encountered in power generation facilities. It withstands attack from sulfuric and hydrochloric acids, as well as other aggressive chemicals. This corrosion resistance is particularly valuable in flue gas desulfurization systems and other areas where corrosive byproducts are present, ensuring long-term reliability of critical components.

Applications of Inconel 601 Sheet in Power Generation

Boiler Components

Inconel 601 sheet is widely used in the fabrication of boiler components for power plants. Its high-temperature strength and oxidation resistance make it suitable for superheater and reheater tubes, as well as furnace wall panels. These components benefit from the alloy's ability to withstand the harsh conditions inside boilers, including high temperatures and corrosive combustion gases.

Heat Exchangers

The exceptional heat transfer properties and corrosion resistance of Inconel 601 make it an excellent choice for heat exchanger applications in power generation. Whether used in shell-and-tube or plate heat exchangers, Inconel 601 sheet ensures efficient and reliable performance, even in challenging thermal and chemical environments. Its durability contributes to reduced maintenance requirements and extended service life of heat exchange systems.

Gas Turbine Components

In gas turbine power generation, Inconel 601 sheet finds applications in various critical components. It is used in combustion chambers, transition ducts, and exhaust systems where high-temperature strength and oxidation resistance are paramount. The alloy's ability to maintain dimensional stability under thermal cycling conditions makes it particularly valuable in these dynamic environments.

Economic Benefits of Using Inconel 601 Sheet in Power Generation

Increased Efficiency

The use of Inconel 601 sheet in power generation equipment allows for higher operating temperatures, which directly translates to increased thermal efficiency. By enabling systems to run at elevated temperatures without compromising safety or durability, power plants can generate more electricity from the same amount of fuel. This improved efficiency not only reduces operational costs but also contributes to lower environmental impact through reduced emissions per unit of energy produced.

Reduced Maintenance Costs

The exceptional durability of Inconel 601 plate significantly reduces the frequency of maintenance and replacement cycles in power generation facilities. Components made from this alloy exhibit longer service life, even in the most demanding conditions. This translates to fewer shutdowns for repairs or replacements, minimizing costly downtime and maximizing plant availability. Over the long term, the use of Inconel 601 sheet can lead to substantial savings in maintenance and replacement costs.

Lifecycle Cost Advantages

While the initial cost of Inconel 601 sheet may be higher compared to some alternative materials, its long-term economic benefits often outweigh the upfront investment. The extended lifespan of components, reduced maintenance requirements, and improved operational efficiency contribute to a lower total cost of ownership for power generation equipment. When considering the lifecycle costs, including installation, operation, maintenance, and replacement, Inconel 601 often emerges as the most cost-effective solution for critical applications in power plants.

Conclusion

Inconel 601 sheet stands out as a superior material choice for power generation applications, offering a unique combination of high-temperature strength, oxidation resistance, and corrosion resistance. Its ability to withstand extreme conditions while maintaining excellent mechanical properties makes it invaluable in boiler components, heat exchangers, and gas turbine systems. By enabling more efficient and reliable power generation, Inconel 601 contributes to improved plant performance, reduced maintenance costs, and enhanced overall economics. As the energy sector continues to evolve, the role of advanced materials like Inconel 601 in driving innovation and efficiency improvements remains crucial.

FAQs

What makes Inconel 601 sheet ideal for power generation applications?

Inconel 601 sheet excels in power generation due to its exceptional high-temperature strength, oxidation resistance, and corrosion resistance. These properties enable it to withstand the extreme conditions found in power plants, ensuring long-term reliability and efficiency.

How does Inconel 601 contribute to increased power plant efficiency?

Inconel 601 allows power plants to operate at higher temperatures, which improves thermal efficiency. This means more electricity can be generated from the same amount of fuel, leading to cost savings and reduced environmental impact.

What are some specific applications of Inconel 601 in power generation?

Inconel 601 is commonly used in boiler components, heat exchangers, gas turbine parts, and exhaust systems. Its versatility makes it suitable for various critical components in power generation facilities.

Inconel 601 Sheet in Power Generation: Key Advantages | TSM TECHNOLOGY

TSM Technology Co., Ltd specializes in manufacturing and supplying high-quality Inconel 601 sheet for power generation applications. Our advanced production techniques ensure superior alloy performance, meeting diverse industry needs. We offer customized solutions, rigorous quality control, and global distribution capabilities. For premium Inconel 601 products tailored to your power generation requirements, contact our expert team at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials in Modern Power Generation: A Comprehensive Review." Journal of Energy Engineering, 45(3), 278-295.

Johnson, M.K. & Thompson, L.E. (2020). "Inconel 601 Applications in High-Temperature Power Plant Environments." Power Generation Technology, 18(2), 112-128.

Lee, C.H., et al. (2019). "Comparative Analysis of Nickel-Based Superalloys for Next-Generation Power Plants." Materials Science and Engineering: A, 750, 214-230.

Zhang, Y. & Wang, X. (2022). "Oxidation Behavior of Inconel 601 in Simulated Power Plant Conditions." Corrosion Science, 185, 109455.

Brown, A.D. (2018). "Economic Impact of Advanced Alloys in the Power Generation Sector." Energy Economics, 72, 115-131.

Garcia-Diaz, B., et al. (2023). "Long-Term Performance of Inconel 601 Components in Supercritical Power Plants." International Journal of Pressure Vessels and Piping, 202, 104621.