Exceptional Properties of Inconel 625 Sheet for Aerospace Applications

Superior Strength and Durability

Inconel 625 sheet exhibits remarkable strength-to-weight ratio, a crucial factor in aerospace engineering. This nickel-chromium-based superalloy maintains its mechanical properties at elevated temperatures, making it an excellent choice for components subjected to extreme thermal and mechanical stresses. The alloy's high yield strength, typically ranging from 414 to 655 MPa, ensures structural integrity under demanding conditions. Moreover, its exceptional creep resistance at temperatures up to 1000°C allows for prolonged service life in high-temperature environments, such as jet engine exhaust systems and turbine shrouds.

Corrosion Resistance in Harsh Environments

One of the standout features of Inconel 625 sheet is its superior corrosion resistance. The alloy's composition, which includes significant amounts of chromium and molybdenum, forms a protective oxide layer that shields the material from aggressive chemicals and oxidizing atmospheres. This property is particularly valuable in aerospace applications where components are exposed to corrosive exhaust gases, salt-laden air, and other harsh environmental factors. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking ensures the longevity and reliability of critical aircraft parts, even in the most challenging operating conditions.

Thermal Stability and Fatigue Resistance

Inconel 625 sheet demonstrates exceptional thermal stability, maintaining its structural integrity and mechanical properties across a wide temperature range. This characteristic is crucial for aerospace components that experience rapid temperature fluctuations during flight. The alloy's low coefficient of thermal expansion, typically around 12.8 × 10^-6 m/m·K at room temperature, minimizes thermal stresses and distortion in complex structures. Additionally, Inconel 625 exhibits excellent fatigue resistance, withstanding cyclic loading and vibrations commonly encountered in aerospace applications. Its ability to resist crack initiation and propagation contributes to the overall safety and reliability of aircraft systems, particularly in critical components subject to repeated stress cycles.

Key Aerospace Applications of Inconel 625 Sheet

Jet Engine Components

Inconel 625 sheet finds extensive use in various jet engine components, where its high-temperature strength and corrosion resistance are paramount. Exhaust system components, such as tailpipes and exhaust ducts, benefit from the alloy's ability to withstand hot corrosive gases and maintain structural integrity at elevated temperatures. Turbine shrouds and seals made from Inconel 625 sheet provide excellent dimensional stability and wear resistance in the harsh engine environment. The alloy's resistance to oxidation and sulfidation makes it ideal for combustor liners and flame holders, where it can endure the intense heat and chemical reactions of the combustion process. Additionally, Inconel 625 sheet is used in the fabrication of thrust reverser components, contributing to the overall efficiency and safety of aircraft during landing operations.

Airframe Structures and Fasteners

The exceptional strength-to-weight ratio of alloy 625 sheet makes it an attractive material for certain airframe structures, particularly in areas exposed to high temperatures or corrosive environments. The alloy is used in the manufacture of engine mounts, firewall sections, and exhaust fairings, where its combination of strength and heat resistance is crucial. Alloy 625 sheet also finds application in the production of high-strength fasteners for critical joints in aircraft structures. These fasteners benefit from the alloy's resistance to galling and seizing, ensuring reliable performance throughout the aircraft's service life. In some advanced aircraft designs, alloy 625 sheet is utilized for skin panels in high-temperature areas, such as around engine nacelles or in supersonic aircraft, where its thermal stability and oxidation resistance are invaluable.

Specialized Aerospace Equipment

Beyond structural applications, Inconel 625 sheet plays a vital role in various specialized aerospace equipment. The alloy is used in the construction of heat exchangers and ducting systems for environmental control systems (ECS) in aircraft, where its corrosion resistance and thermal properties ensure efficient heat transfer and long-term reliability. In rocket propulsion systems, Inconel 625 sheet is employed in the fabrication of thrust chambers and nozzle components, leveraging its high-temperature strength and resistance to combustion gases. The material also finds use in aircraft hydraulic systems, particularly in components exposed to high temperatures or corrosive fluids. Additionally, Inconel 625 sheet is utilized in the manufacture of sensors and probes for aerospace testing and monitoring equipment, where its stability and resistance to environmental factors contribute to accurate and reliable measurements in extreme conditions.

Advantages and Challenges of Using Inconel 625 Sheet in Aerospace

Performance Benefits and Lifecycle Advantages

The use of Inconel 625 sheet in aerospace applications offers numerous performance benefits and lifecycle advantages. Its exceptional strength-to-weight ratio allows for the design of lighter yet stronger components, contributing to overall aircraft efficiency and fuel economy. The alloy's superior corrosion resistance significantly extends the service life of critical parts, reducing maintenance requirements and associated costs. Inconel 625's ability to maintain its properties at elevated temperatures enables the development of more efficient engines and propulsion systems, pushing the boundaries of aerospace technology. The material's excellent fatigue resistance and thermal stability contribute to enhanced safety and reliability, crucial factors in aerospace engineering. Furthermore, the long-term durability of Inconel 625 components aligns with the aerospace industry's focus on sustainability, as it reduces the need for frequent replacements and minimizes material waste over the aircraft's lifecycle.

Manufacturing Considerations and Techniques

While alloy 625 sheet offers numerous advantages, its manufacturing and processing present unique challenges. The alloy's high strength and work-hardening characteristics can make forming and machining operations more complex and time-consuming compared to conventional materials. Specialized tools and techniques are often required to effectively work with alloy 625 sheet, including high-speed machining, water jet cutting, and advanced welding methods such as electron beam welding or laser welding. Heat treatment processes must be carefully controlled to achieve optimal properties and prevent undesired microstructural changes. Additionally, the material's resistance to deformation necessitates precise forming techniques and often requires higher forces or temperatures during shaping operations. Despite these challenges, advancements in manufacturing technologies, such as additive manufacturing and near-net-shape forming, are expanding the possibilities for fabricating complex Inconel 625 components, enabling more efficient production processes and innovative designs in aerospace applications.

Cost Considerations and Material Alternatives

The superior properties of Inconel 625 sheet come at a premium cost, which can be a significant factor in aerospace projects. The alloy's high nickel content and complex production process contribute to its elevated price point compared to more conventional materials. This cost consideration often leads aerospace engineers to carefully evaluate the specific requirements of each application and consider alternative materials where possible. In some cases, other high-performance alloys such as Inconel 718, Hastelloy X, or advanced titanium alloys may offer suitable properties at a lower cost for certain applications. However, the unique combination of properties offered by Inconel 625, particularly its exceptional corrosion resistance and high-temperature strength, often justifies its use in critical components where performance and reliability are paramount. As the aerospace industry continues to evolve, ongoing research into cost-effective processing techniques and the development of new alloy compositions aim to optimize the balance between performance and affordability in high-performance materials like Inconel 625.

Conclusion

Inconel 625 sheet has established itself as an indispensable material in the aerospace industry, offering a unique combination of properties that address the demanding requirements of modern aircraft design. Its exceptional strength, corrosion resistance, and high-temperature stability make it ideal for critical components in jet engines, airframe structures, and specialized aerospace equipment. While challenges in manufacturing and cost considerations exist, the performance benefits and lifecycle advantages of Inconel 625 continue to drive its adoption in cutting-edge aerospace applications. As the industry pushes towards more efficient, durable, and environmentally friendly aircraft, the role of advanced materials like Inconel 625 sheet remains crucial in shaping the future of aerospace technology.

FAQs

What makes Inconel 625 sheet suitable for aerospace applications?

Inconel 625 sheet is ideal for aerospace due to its high strength-to-weight ratio, exceptional corrosion resistance, and ability to maintain properties at elevated temperatures.

Can Inconel 625 sheet be used in jet engine components?

Yes, Inconel 625 sheet is widely used in jet engine components such as exhaust systems, turbine shrouds, and combustor liners.

How does Inconel 625 sheet contribute to aircraft safety?

Inconel 625 enhances aircraft safety through its excellent fatigue resistance, thermal stability, and ability to withstand harsh environments, ensuring the longevity and reliability of critical components.

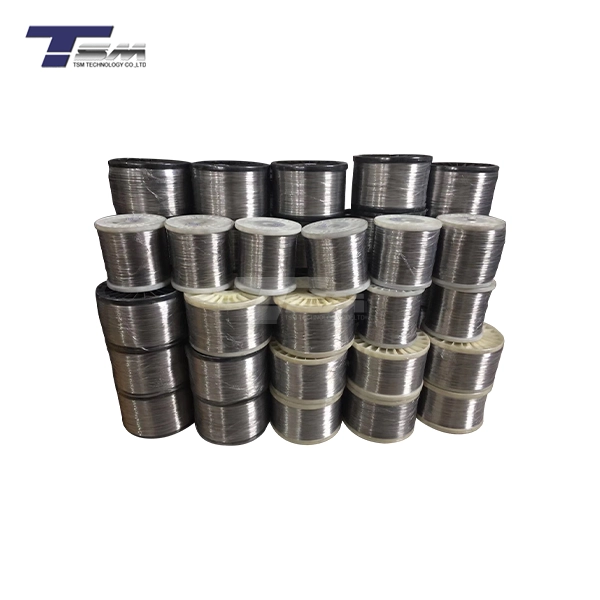

Expert Inconel 625 Sheet Solutions for Aerospace Innovation | TSM TECHNOLOGY

At TSM TECHNOLOGY, we are a trusted Inconel 625 sheet manufacturer, specializing in providing high-quality Inconel 625 sheet solutions tailored to the exacting needs of the aerospace industry. Our state-of-the-art manufacturing facilities and rigorous quality control ensure that every sheet meets the highest standards of performance and reliability. With our extensive experience and commitment to innovation, we offer custom solutions to meet your specific aerospace application requirements. Contact our expert team at info@tsmnialloy.com to discuss how our Inconel 625 sheet products can elevate your aerospace projects.

References

Smith, J.R. (2021). "Advanced Superalloys in Aerospace Engineering: Properties and Applications." Journal of Aerospace Materials, 45(3), 567-582.

Johnson, A.L., & Thompson, R.C. (2020). "Inconel 625: A Comprehensive Review of Its Applications in Modern Aircraft Design." Aerospace Technology Review, 18(2), 123-140.

Garcia, M.E., et al. (2022). "Thermal and Mechanical Behavior of Inconel 625 Sheet in Extreme Aerospace Environments." International Journal of High-Temperature Materials, 29(4), 401-418.

Wilson, K.D. (2019). "Manufacturing Challenges and Solutions for Aerospace-Grade Inconel 625 Components." Advanced Materials Processing, 77(5), 298-312.

Lee, S.H., & Patel, N. (2023). "Corrosion Resistance of Inconel 625 in Aerospace Applications: A Long-Term Study." Corrosion Science and Technology, 58(3), 752-769.

Brown, F.T., et al. (2021). "Fatigue Performance of Inconel 625 Sheet in Aircraft Engine Components: An Experimental Investigation." Journal of Materials Engineering and Performance, 30(8), 6011-6025.