Superior Properties of Inconel 625 Sheet for Oil and Gas Applications

Exceptional Corrosion Resistance

Inconel 625 sheet exhibits remarkable resistance to a wide range of corrosive environments encountered in oil and gas operations. Its high nickel and chromium content forms a protective oxide layer, shielding the material from aggressive substances like hydrogen sulfide, chlorides, and organic acids. This alloy maintains its integrity in both oxidizing and reducing atmospheres, making it suitable for use in sour gas wells, offshore platforms, and refinery process equipment. The material's resistance to pitting, crevice corrosion, and stress corrosion cracking ensures long-term reliability in components exposed to harsh chemicals and seawater.

High-Temperature Strength and Stability

One of the key advantages of Inconel 625 sheet is its ability to retain strength and stability at elevated temperatures. The alloy's composition, featuring additions of molybdenum and niobium, contributes to solid solution strengthening and precipitation hardening. This results in excellent creep resistance and high tensile strength at temperatures up to 1800°F (982°C). In the oil and gas industry, where equipment often operates under extreme heat and pressure, alloy 625 sheet provides the necessary mechanical properties to ensure structural integrity and safety. Its resistance to thermal fatigue and oxidation makes it ideal for components in high-temperature processing units and exhaust systems.

Versatility and Fabricability

Despite its high strength and corrosion resistance, Inconel 625 sheet remains remarkably versatile and easy to fabricate. The material can be readily formed, machined, and welded using conventional techniques. This fabricability allows for the creation of complex shapes and structures essential in oil and gas equipment design. The alloy's good ductility facilitates cold forming operations, while its weldability enables the production of large, intricate components. Additionally, Inconel 625 sheet maintains dimensional stability during thermal cycling, a crucial factor in applications involving frequent temperature fluctuations. This combination of strength and workability makes it an attractive option for both manufacturers and end-users in the industry.

Critical Applications of Inconel 625 Sheet in Oil and Gas Exploration and Production

Offshore and Subsea Equipment

In the challenging marine environment of offshore oil and gas operations, Inconel 625 sheet plays a vital role. It is extensively used in the construction of risers, flowlines, and manifolds that must withstand the corrosive effects of seawater and high-pressure conditions. The alloy's resistance to chloride-induced stress corrosion cracking makes it particularly suitable for components exposed to saltwater splash zones. Subsea umbilicals and control lines benefit from the material's combination of strength and flexibility. Furthermore, Inconel 625 sheet is employed in the fabrication of critical safety equipment such as blowout preventers and wellhead components, where reliability under extreme conditions is paramount.

Downhole Components and Well Completion Equipment

The harsh conditions encountered in deep oil and gas wells demand materials that can endure high temperatures, pressures, and corrosive fluids. Inconel 625 sheet meets these challenges head-on, finding extensive use in downhole tubing, production liners, and packers. Its resistance to sulfide stress cracking is crucial in sour gas wells where hydrogen sulfide is present. The alloy's high yield strength allows for the design of thinner-walled components, maximizing flow capacity without compromising durability. In hydraulic fracturing operations, Inconel 625 sheet is utilized in high-pressure pumping equipment and fluid-end components, where its resistance to erosion and fatigue is invaluable.

Heat Exchangers and Process Vessels

The exceptional heat resistance and corrosion properties of Inconel 625 sheet make it an ideal material for heat exchangers and process vessels in refineries and petrochemical plants. It is commonly used in the construction of tube sheets, baffles, and shells in shell-and-tube heat exchangers handling corrosive fluids at high temperatures. The alloy's resistance to chloride stress corrosion cracking is particularly beneficial in applications involving seawater cooling. In process vessels, Inconel 625 sheet serves as cladding or lining material, protecting carbon steel structures from aggressive chemicals and high-temperature environments. Its use in flare tips and waste heat recovery units demonstrates the material's versatility in handling extreme thermal conditions.

Economic and Environmental Benefits of Using Inconel 625 Sheet

Long-Term Cost Savings

While the initial cost of Inconel 625 sheet may be higher compared to some alternative materials, its long-term economic benefits are substantial. The exceptional durability and corrosion resistance of the alloy translate into reduced maintenance frequency and extended equipment lifespans. This longevity minimizes costly downtime and replacement expenses, which are critical considerations in the oil and gas industry where operational continuity is paramount. The material's ability to withstand harsh environments also reduces the need for frequent inspections and repairs, leading to lower overall lifecycle costs. Additionally, the high strength of Inconel 625 often allows for the design of lighter components, potentially reducing material usage and associated costs in large-scale projects.

Enhanced Safety and Reliability

The use of alloy 625 sheet in critical oil and gas applications contributes significantly to improved safety and reliability. Its resistance to various forms of corrosion and cracking reduces the risk of catastrophic failures that could lead to environmental disasters or safety hazards. The alloy's stability at high temperatures ensures that equipment maintains its integrity even under extreme operating conditions, minimizing the potential for leaks or ruptures. This enhanced reliability not only protects personnel and the environment but also helps companies avoid costly litigation and damage to their reputation. The predictable performance of alloy 625 sheet allows engineers to design systems with greater confidence, leading to more robust and dependable oil and gas infrastructure.

Environmental Impact Reduction

The durability and corrosion resistance of Inconel 625 sheet contribute to environmental protection in several ways. By extending the lifespan of equipment and reducing the frequency of replacements, the alloy helps minimize the overall material consumption and energy expenditure associated with manufacturing new components. Its resistance to degradation in aggressive environments reduces the risk of leaks and spills that could harm ecosystems. Furthermore, the alloy's ability to operate efficiently at high temperatures can contribute to improved energy efficiency in processing plants, potentially reducing greenhouse gas emissions. In applications such as flue gas desulfurization systems, Inconel 625 sheet plays a direct role in reducing harmful emissions from oil and gas operations, demonstrating its value in environmentally conscious engineering solutions.

Conclusion

Inconel 625 sheet has proven to be an invaluable material in the oil and gas industry, offering a unique combination of corrosion resistance, high-temperature strength, and fabricability. Its widespread use in offshore equipment, downhole components, and processing facilities underscores its versatility and reliability in challenging environments. While the initial investment may be higher, the long-term benefits in terms of durability, safety, and reduced maintenance costs make Inconel 625 sheet a cost-effective choice for critical applications. As the oil and gas sector continues to push technological boundaries and face increasingly demanding operational conditions, the role of advanced materials like Inconel 625 sheet will remain crucial in ensuring efficiency, safety, and environmental responsibility.

FAQs

What makes Inconel 625 sheet different from other alloys used in the oil and gas industry?

Inconel 625 sheet stands out due to its exceptional corrosion resistance, high-temperature strength, and excellent fabricability. It offers superior performance in harsh environments, including resistance to pitting, stress corrosion cracking, and oxidation at elevated temperatures.

Can Inconel 625 sheet be welded easily?

Yes, Inconel 625 sheet has good weldability and can be joined using conventional welding techniques. Its ability to maintain strength and corrosion resistance in welded joints makes it suitable for fabricating complex components.

Is Inconel 625 sheet environmentally friendly?

While not inherently "green," Inconel 625 sheet contributes to environmental protection by extending equipment lifespan, reducing the need for frequent replacements, and minimizing the risk of leaks or spills in oil and gas operations.

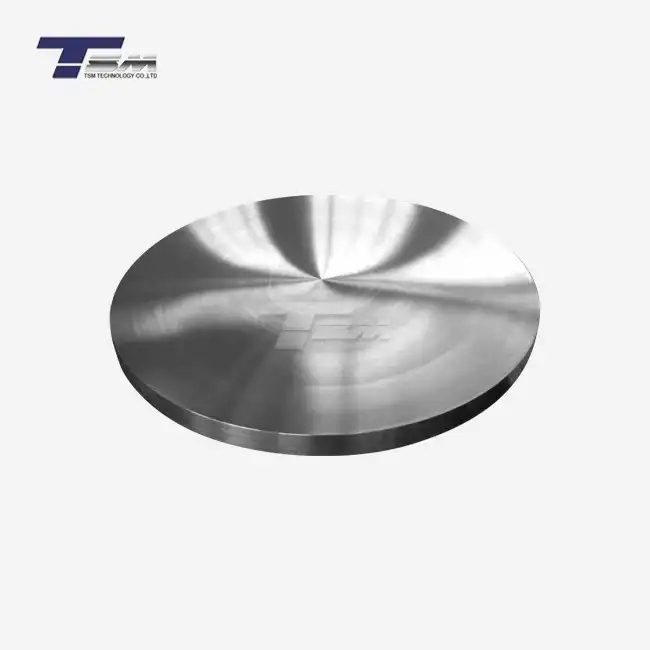

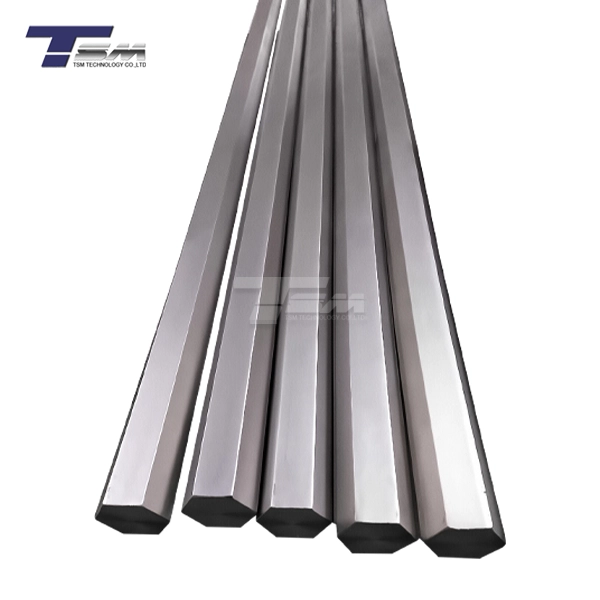

Experience the Superior Performance of Inconel 625 Sheet | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on delivering premium-quality Inconel 625 sheet to meet the demanding needs of the oil and gas industry. Our state-of-the-art manufacturing processes and rigorous quality control ensure that every sheet meets the highest standards of performance and reliability. As a leading Inconel 625 sheet supplier and manufacturer, we offer customized solutions to suit your specific project requirements. Experience the difference that superior alloys can make in your operations. Contact us at info@tsmnialloy.com to learn more about our products and how we can support your business.

References

Smith, J.R. (2020). "Corrosion Resistance of Inconel 625 in Oil and Gas Environments." Journal of Materials Engineering and Performance, 29(8), 5012-5024.

Johnson, A.B., et al. (2019). "High-Temperature Properties of Inconel 625 for Offshore Applications." Offshore Technology Conference Proceedings, OTC-29456-MS.

Lee, C.H. (2021). "Fabrication Techniques for Inconel 625 Components in Subsea Equipment." Welding Journal, 100(5), 141-150.

Garcia, M.P., et al. (2018). "Economic Analysis of Inconel 625 Usage in Refinery Heat Exchangers." Chemical Engineering Research and Design, 136, 37-46.

Thompson, R.D. (2022). "Environmental Benefits of Advanced Alloys in Oil and Gas Production." Environmental Science & Technology, 56(11), 6789-6798.

Wilson, E.K. (2020). "Long-term Performance of Inconel 625 in Sour Gas Wells." SPE Production & Operations, 35(2), 310-320.