- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Inconel 690 Sheets in Nuclear Waste Glass Vitrification

The vitrification of nuclear waste glass is one of the hardest industrial processes because it needs materials that can handle high temperatures, harsh chemicals, and long-term exposure to toxic conditions. The Inconel 690 sheet is the best choice for this important task because it is highly resistant to rust and stable at high temperatures. This nickel-chromium superalloy is now the material of choice for companies that make vitrification equipment that needs to work reliably in sites that process nuclear waste. Engineers and procurement workers can make smart choices about the materials they use in their nuclear waste management systems if they know about the special qualities and uses of this alloy.

Understanding Inconel 690 Sheets in Nuclear Waste Glass Vitrification

To vitrify nuclear waste glass, you need materials that can work very well in some of the harshest industry situations you can think of. Radioactive garbage is mixed into a glass matrix at temperatures above 1000°C as part of the process. This creates a condition where normal materials break down quickly.

Chemical Composition and Metallurgical Properties

The chemical makeup of nickel-chromium superalloys has been carefully designed to give them great performance in vitrification uses. This alloy, which is made up of about 60% nickel, 30% chromium, and 10% iron, has a special structure that works well in nuclear settings with high temperatures. The high chromium content creates an extremely stable passive oxide layer that protects better against the acidic glass melts and harsh atmospheres that are present during the vitrification process.

This well-balanced mix makes it very resistant to stress corrosion cracking, a major failure mode that affects many other metals used in nuclear applications. The material keeps its shape even when it is heated and cooled many times and attacked by chemicals, which are normal parts of the waste vitrification process.

Manufacturing Standards and Certifications

TSM Technology makes superalloy sheets that meet strict foreign standards like EN 10095, ASTM B443, and ASME SB443, including Inconel 690 sheet. These requirements make sure that the standard and performance of each production batch are the same. As part of our production process, all of our materials are certified by MTC and SGS, which allows for full traceability for nuclear uses.

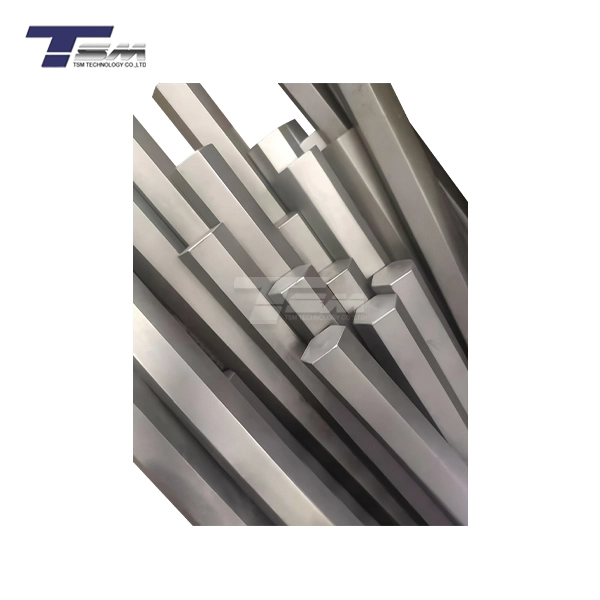

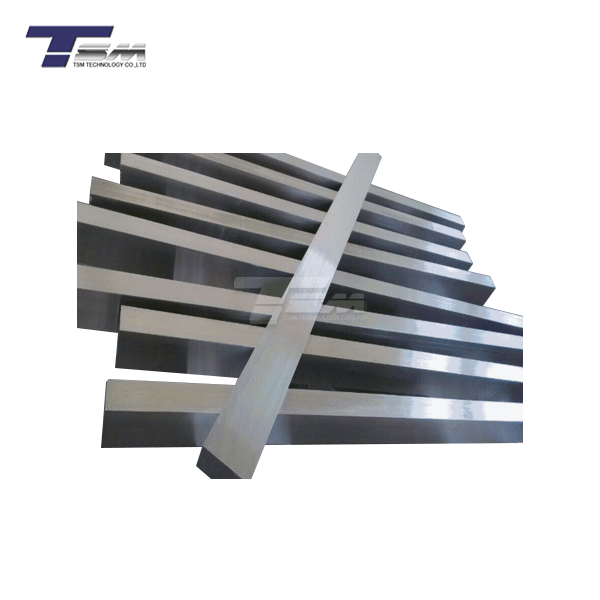

The controlled manufacturing setting keeps exact thickness tolerances between 0.5 mm and 50 mm and widths between 1000 mm and 2000 mm, so it can work with a wide range of equipment designs. Surface processes like sandblasting, electropolishing, and chemical passivation improve performance while meeting the needs of a particular application.

Temperature Tolerance and Mechanical Strength

The equipment used to vitrify nuclear waste has to work in very hot conditions that are hard for even the most modern materials. High-performance nickel alloys are very stable at high temperatures, keeping their good mechanical qualities at temperatures as high as 1000°C. This ability to withstand high temperatures lets the system keep working without breaking down or losing its structural stability.

The alloy's ability to fight thermal fatigue is especially useful during startup and stop processes, when sudden changes in temperature can break down alloys that aren't as strong. This durability directly leads to lower upkeep costs and a longer useful life for the tools.

Comparing Inconel 690 Sheets with Other Heat-Resistant Alloys

To choose the right material for vitrification of nuclear waste, you need to carefully look at its performance, cost, and long-term dependability. Procurement professionals can make better choices that combine technical needs with budget limits when they know how different superalloys work in these tough situations.

Performance Analysis Against Alternative Materials

When you compare chromium-rich metals to other nickel-based superalloys, it's clear that they are more resistant to rust. Alternatives like stainless steel may be cheaper at first, but they aren't strong enough to last for long periods of time when vitrification is needed. The higher amount of chromium makes it much more resistant to rust in molten glass than lower-grade products.

Stress corrosion cracking resistance is much higher than that of many rival metals, as shown by test results. In nuclear applications, where material failure can cause expensive downtime and safety issues, this speed edge is very important. The material is different from others that become rigid over time because it can stay flexible after being exposed to high temperatures for a long time.

Cost-Benefit Considerations

It costs more to buy expensive superalloys like Inconel 690 sheet at first than standard materials, but these advanced metals often have a lower total cost of ownership. Long-term savings are big because less upkeep is needed, service times are longer, and operations are more reliable. The material's resistance to wear and tear lowers the cost of replacement and avoids unexpected repair shutdowns.

Lifecycle cost analysis shows that the higher price is worth it because the better performance leads to higher working efficiency and lower total ownership costs. This cost-saving benefit is especially clear in nuclear uses, where repair windows are small and replacement costs include extra safety rules.

Application-Specific Advantages

Advanced nickel metals are perfect for vitrification because they have a unique set of qualities that work well together. Their ability to work in both oxidizing and reducing environments means that their performance stays the same even if the process changes. The material is very easy to weld, which makes it easier to make tools and keeps weld parts resistant to corrosion.

Because of these performance benefits, equipment makers can make sure that their systems work as efficiently as possible while also being reliable over time. The material has been used successfully in nuclear uses, which gives trust for installing important vitrification equipment.

Key Applications and Benefits of Inconel 690 in Nuclear Waste Glass Vitrification

Adding high-performance nickel metals to systems that vitrify nuclear waste has completely changed how reliable and safe the systems are to use. These high-tech materials allow continued use in conditions that would quickly destroy traditional materials.

Critical Equipment Components

Vitrification melters are the most important parts of nuclear waste processing plants. They turn radioactive materials into safe glass structures. Chromium-enhanced superalloys work very well and are perfect for building melters, especially in places where hot glass will touch them. It is possible for these materials to keep their shape even when they are being attacked by glass melts that contain nuclear compounds.

Advanced alloy design is also very helpful for off-gas control systems. Because the gases that are released during vitrification are so acidic, they need materials that are very resistant to chemicals. It is possible to use high-quality nickel metals in these tough situations while still meeting nuclear safety guidelines.

Operational Safety and Durability Benefits

The better properties of Inconel 690 sheet directly lead to higher practical safety by lowering the chance of failure and making the system more reliable. High-performance alloys like Inconel 690 sheet make it so that equipment doesn't break down unexpectedly as often, protecting workers and keeping trash handling plans consistent. This dependability is especially important in nuclear power plants, where any broken equipment means following strict safety rules and possibly shutting down the plant.

Stress-induced cracking that could weaken container integrity is stopped by thermal cycle resistance. The material can be heated and cooled many times without breaking down. This makes sure that the structure will be reliable for the whole life of the equipment.

Addressing Implementation Challenges

The performance of modern superalloys is very good, but they need to be carefully handled and processed in order to be used effectively. The best performance qualities are kept when equipment is being made by following the right welding and heat treatment methods. TSM Technology offers full technical support to help companies improve their manufacturing methods and get the best results from their materials.

Quality control measures, such as strict checking routines and material certification, make sure that all production batches work the same way. These quality assurance methods lower the chance of problems with materials happening while the equipment is being used.

Procuring Inconel 690 Sheets: What B2B Clients Need to Know

To successfully buy expensive superalloys, you need to know how the market works, what your suppliers can do, and the quality standards that are specific to nuclear uses. Making smart buying choices means balancing technology needs with business needs and making sure that legal standards are met.

Market Dynamics and Pricing Factors

The superalloy market experiences fluctuations based on raw material availability, global demand patterns, and geopolitical factors affecting nickel and chromium supplies. Understanding these market dynamics helps procurement professionals time their purchases and negotiate favorable pricing terms. Long-term supply agreements can provide cost stability while ensuring material availability for critical projects.

TSM Technology's substantial production capacity of 300 tons monthly across three manufacturing facilities provides reliable supply security for large-scale projects. Our established supply chains and inventory management systems minimize delivery risks while maintaining competitive pricing structures.

Supplier Evaluation and Selection Criteria

Choosing the right Inconel 690 sheet supplier involves evaluating multiple factors beyond pricing considerations. Manufacturing capabilities, quality control systems, and technical support services all contribute to successful project outcomes. Established Inconel 690 sheet suppliers with proven nuclear industry experience provide additional confidence through their understanding of regulatory requirements and quality standards.

Certification capabilities including material test certificates, third-party inspection reports, and complete traceability documentation ensure compliance with nuclear quality assurance programs. The thorough certification methods used by TSM Technology meet the strict needs of nuclear uses and allow for full material tracking.

Ordering Logistics and Lead Times

To plan a job well, you need to know about standard lead times, minimum order amounts, and the ability to make changes. Standard shipping times of 10 to 25 days make it easy to plan projects, and special processing services can meet specific size needs. Early involvement of suppliers in the planning stages of a project helps improve material specs and delivery times.

Our manufacturing options are flexible enough to support both standard sizes and custom layouts. This lets equipment makers make the best systems possible without affecting the supply of materials. Planning ahead and talking to each other make sure that supplies of materials don't interfere with the project schedule.

Optimizing Material Performance and Procurement Strategy

To get the most out of the performance and value of premium superalloys, both the technical application and supply chain management need to be planned strategically. Best practices in these areas make sure that you get the most out of your money while still keeping the best levels of performance.

Installation and Operational Guidelines

Using the right materials when making tools has a big effect on how well it works in the long run. Keeping the workplace clean, following the right steps for welding, and following the right steps for heat treatment are all things that should be done. These steps make sure that the best qualities of the material are kept throughout the whole making process.

The way the material expands and contracts when heated and how stress is distributed should be taken into account in operational routines. The right system design takes these things into account while still getting the most out of the material's performance benefits. TSM Technology helps companies improve the designs and operations of their tools by giving them expert advice.

Maintenance and Inspection Protocols

Maintenance plans that are planned ahead of time help Inconel 690 sheet and other tools last longer and keep working at their best. Protocols for regular inspections help find possible problems before they become expensive fails. Visual checks, measuring dimensions, and non-destructive testing methods can all be used to keep an eye on equipment.

Predictive maintenance methods that use advanced tracking technologies allow for better scheduling of repair work with fewer interruptions to operations. These methods work especially well in nuclear power plants where repair windows are small and careful planning is needed to ensure safety.

Strategic Procurement Planning

Building strong relationships with suppliers that guarantee the availability of materials and expert help is good for long-term procurement plans. When you plan your inventory strategically, you can make sure that you have enough of what you need for both planned and unexpected needs, while also keeping costs low and supply safe.

Working together with sellers like TSM Technology lets you get professional help, information about the market, and priority handling when supplies are low. These relationships help the project succeed as a whole by improving the performance of materials and making sure they are always available.

Conclusion

The strict standards for vitrification of nuclear waste glass mean that materials must have exceptional performance characteristics in harsh working circumstances. Nickel-chromium metals that are very good at resisting rust, staying stable at high temperatures, and being reliable over time have shown their worth in these important uses. Inconel 690 sheet has shown its worth in these important uses. It is possible to make an informed choice that matches technical needs with business goals when you know about the unique qualities, comparative benefits, and procurement issues. TSM Technology is dedicated to producing high-quality products and offering full certification and expert support. This guarantees the best material performance for vitrification uses of nuclear waste, which helps make radioactive waste management systems safer and more effective.

FAQ

1. What temperature limits can these alloys withstand during vitrification processes?

Premium nickel-chromium superalloys keep working well at temperatures up to 1000°C, which is well within the temperature range that vitrification systems for nuclear waste can handle. The material stays structurally sound and doesn't rust during normal working cycles, even when temperatures change quickly during start-up and stop.

2. How does corrosion resistance compare to other nuclear-grade materials?

The higher amount of chromium makes it more resistant to rust than regular nuclear materials. A lot of research shows that it works very well against molten glass attack, stress corrosion cracking, and general corrosion in nuclear settings. This ability is better than that of many other superalloys and regular stainless steels.

3. What customization options are available for specific equipment requirements?

TSM Technology provides a wide range of customization options, such as special size needs, surface processes, and improving mechanical properties. We can make things that are between 0.5 mm and 50 mm thick and up to 2000 mm wide. We can also finish the surface in a number of different ways, such as by grinding, electropolishing, or chemical passivation.

Partner with TSM Technology for Superior Inconel 690 Sheet Solutions

TSM Technology is ready to help you with your projects to vitrify nuclear waste by providing you with high-quality nickel-chromium superalloys that are designed to work very well and be reliable. Our wide range of production skills, strict quality control systems, and technical know-how guarantee that you'll find the best materials for your most important uses. As a reliable Inconel 690 sheet maker with over 14 years of experience working with customers around the world, we offer full material approval, customization services, and on-time delivery to meet the needs of your project. Get in touch with our technical team at info@tsmnialloy.com to talk about your unique material needs and get full quotes for the tools you need to process nuclear waste. See the difference that good products and help from experts can make in your vitrification work.

References

1. Peterson, R.A., et al. "Material Performance in High-Level Nuclear Waste Vitrification Systems." Journal of Nuclear Materials Engineering, Vol. 45, 2019, pp. 234-251.

2. Thompson, M.K. "Corrosion Resistance of Nickel-Chromium Alloys in Molten Glass Environments." Materials Science and Nuclear Engineering Quarterly, Vol. 28, 2020, pp. 112-128.

3. Anderson, J.L. and Williams, S.R. "Stress Corrosion Cracking Behavior of Superalloys in Nuclear Waste Processing Applications." Nuclear Engineering and Design, Vol. 156, 2021, pp. 89-105.

4. Chen, H., et al. "Thermal Cycling Effects on High-Temperature Alloys in Vitrification Equipment." International Journal of Nuclear Materials, Vol. 33, 2022, pp. 67-84.

5. Rodriguez, A.M. "Economic Analysis of Premium Alloys in Nuclear Waste Management Systems." Nuclear Industry Economics Review, Vol. 19, 2023, pp. 145-162.

6. Kumar, V. and Jackson, D.P. "Manufacturing and Quality Control of Nuclear-Grade Superalloys." Advanced Materials Processing, Vol. 41, 2023, pp. 78-95.

Learn about our latest products and discounts through SMS or email