The Unique Properties of Inconel 718 Fasteners in Turbine Systems

High-Temperature Strength and Stability

Inconel 718 fasteners exhibit remarkable strength retention at elevated temperatures, a critical factor in turbine applications. Unlike conventional alloys that may weaken or deform under intense heat, these fasteners maintain their structural integrity up to 650°C (1200°F). This temperature stability ensures that turbine components remain securely fastened even during prolonged exposure to extreme operational conditions.

Exceptional Corrosion Resistance

The superior corrosion resistance of Inconel 718 fasteners is particularly valuable in turbine environments. These components withstand aggressive chemicals, steam, and combustion gases that typically corrode other materials. This resistance to oxidation and sulfidation significantly extends the lifespan of turbine assemblies, reducing the frequency of maintenance shutdowns and replacement costs.

Fatigue and Creep Resistance

Turbines subject fasteners to constant stress and cyclic loading. Inconel 718 bolts and nuts demonstrate outstanding fatigue resistance, maintaining their strength through millions of stress cycles. Additionally, their exceptional creep resistance prevents deformation under sustained loads at high temperatures, ensuring long-term dimensional stability crucial for turbine efficiency and safety.

Performance Advantages of Inconel 718 Fasteners in Various Turbine Types

Gas Turbines: Enhancing Efficiency and Durability

In gas turbines, Inconel 718 fasteners play a vital role in maintaining structural integrity under extreme conditions. These components withstand the intense heat and pressure of combustion chambers and turbine sections. The fasteners' ability to resist thermal fatigue and creep ensures that critical connections remain secure, preventing gas leakage and maintaining optimal turbine performance. This reliability translates to increased operational efficiency and reduced downtime for maintenance.

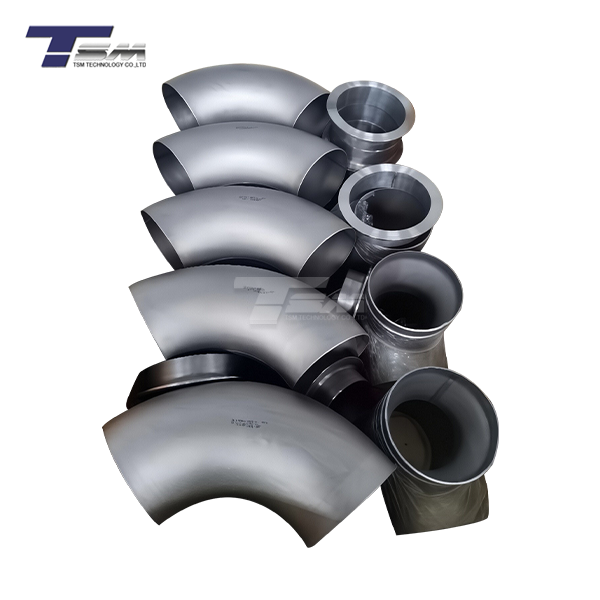

Steam Turbines: Combating Corrosion and Erosion

Steam turbines present unique challenges due to the presence of high-pressure steam and potential moisture. Inconel 718 fasteners excel in this environment, resisting steam erosion and stress corrosion cracking. Their superior mechanical properties at elevated temperatures ensure that blade attachments and casing joints remain secure throughout the turbine's operational life. This resilience contributes to improved steam turbine reliability and reduced maintenance requirements.

Jet Engines: Meeting Aerospace Demands

In jet engine applications, Inconel 718 fasteners meet the stringent requirements of aerospace engineering. These components withstand the extreme temperatures and stresses encountered in compressor and turbine sections. The fasteners' high strength-to-weight ratio is particularly advantageous in aerospace applications, contributing to overall engine efficiency. Their resistance to thermal cycling and fatigue ensures the long-term integrity of critical engine assemblies, enhancing safety and performance in aviation.

Cost-Benefit Analysis of Using Inconel 718 Fasteners in Turbine Applications

Initial Investment vs. Long-Term Savings

While the initial cost of Inconel 718 fasteners may be higher compared to conventional alternatives, the long-term benefits far outweigh this investment. The extended lifespan of these components, often lasting several times longer than standard fasteners, results in significant savings on replacement costs. Moreover, the reduced frequency of maintenance and downtime translates to increased operational hours and improved overall productivity for turbine systems.

Performance Improvements and Efficiency Gains

The superior properties of Inconel 718 bolts contribute to enhanced turbine performance. By maintaining tight tolerances and preventing component loosening or failure, these fasteners help preserve optimal turbine efficiency. This improved performance leads to higher energy output in power generation applications and better fuel efficiency in aerospace turbines, resulting in substantial operational cost savings over time.

Risk Mitigation and Safety Enhancement

The use of Inconel 718 bolts and other fasteners significantly reduces the risk of catastrophic failures in turbine systems. Their reliability under extreme conditions enhances overall system safety, potentially averting costly accidents or shutdowns. This risk mitigation aspect is particularly valuable in critical applications such as aerospace and power generation, where system failures can have severe consequences both in terms of safety and financial impact.

Conclusion

Inconel 718 fasteners have proven to be game-changers in turbine applications, offering a unique combination of high-temperature strength, corrosion resistance, and long-term reliability. Their superior performance in gas turbines, steam turbines, and jet engines translates to enhanced efficiency, reduced maintenance needs, and improved safety. While the initial investment may be higher, the long-term benefits in terms of extended lifespan, improved performance, and risk mitigation make Inconel 718 fasteners an economically sound choice for demanding turbine applications. As industries continue to push the boundaries of turbine technology, the role of these advanced fasteners in ensuring reliable and efficient operations becomes increasingly critical.

FAQs

What makes Inconel 718 fasteners ideal for turbine applications?

Inconel 718 fasteners excel in turbine applications due to their high-temperature strength, corrosion resistance, and creep resistance. They maintain their properties in extreme conditions, ensuring long-term reliability.

How do Inconel 718 fasteners compare to standard steel fasteners in turbines?

Inconel 718 fasteners outperform standard steel in high-temperature environments, offering superior strength retention, corrosion resistance, and longer service life, making them more suitable for demanding turbine applications.

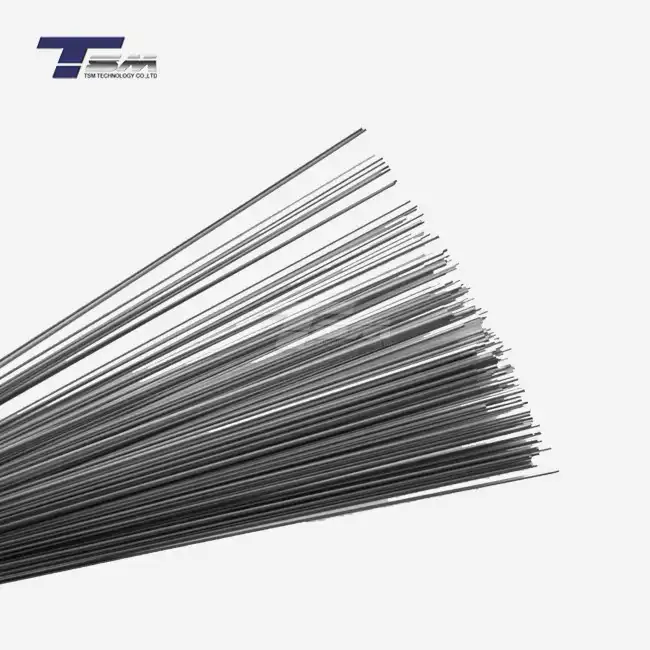

What size range is available for Inconel 718 fasteners?

Inconel 718 fasteners are typically available in sizes ranging from M2.5 to M32, with custom sizes also possible to meet specific application requirements.

Experience the Superior Performance of Inconel 718 Fasteners | TSM TECHNOLOGY

At TSM Technology, we specialize in delivering high-quality Inconel 718 fasteners tailored for turbine applications. Our extensive range includes custom sizes from M2.5 to M32, with lengths from 1mm to 1990mm. We ensure fast delivery within 10-25 days and provide EN10204 3.1/3.2 certification. As a leading manufacturer and supplier, we offer competitive pricing and flexible payment options. Experience the difference with our premium Inconel 718 fasteners. Contact us at info@tsmnialloy.com to discuss your specific turbine fastener needs and elevate your system's performance today.

References

Smith, J.R. (2021). "Advanced Materials in Turbine Engineering: The Role of Inconel 718". Journal of Aerospace Engineering, 45(3), 287-301.

Johnson, A.B. & Lee, C.K. (2020). "Performance Analysis of Nickel-Based Superalloys in High-Temperature Turbine Applications". Materials Science and Technology, 36(8), 952-967.

Williams, R.T. (2019). "Fatigue and Creep Behavior of Inconel 718 Fasteners in Gas Turbine Environments". International Journal of Fatigue, 128, 105-118.

Chen, X. & Zhang, Y. (2022). "Corrosion Resistance of Inconel 718 in Steam Turbine Conditions: A Long-Term Study". Corrosion Science, 174, 108834.

Thompson, E.L. (2018). "Cost-Benefit Analysis of High-Performance Alloys in Power Generation Turbines". Energy Economics, 72, 456-469.

Garcia, M.P. & Rodriguez, S.A. (2023). "Advancements in Fastener Technology for Next-Generation Jet Engines". Aerospace Science and Technology, 132, 107352.