- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Inside the Industrial Metal Polishing Process

The industrial metal polishing process is a fascinating blend of science, precision, and craftsmanship. It transforms raw, rugged metal surfaces into smooth, gleaming components ready for high-performance applications. This meticulous procedure enhances not only the aesthetic appeal but also the durability and functionality of metals, including superior alloys like Monel, Inconel, and Hastelloy. At its core, polishing involves a series of abrasive techniques, chemical treatments, and expert inspections to ensure the metal meets stringent quality standards. Whether it's for aerospace, marine, or precision engineering, the journey from rough stock to polished perfection is nothing short of remarkable.

The Art and Science of Metal Polishing

Polishing industrial metals is more than just a surface-level enhancement; it's a critical step in ensuring the material's longevity and performance. When working with superior alloys, the stakes are even higher, as these materials are often destined for extreme environments where corrosion resistance and strength are non-negotiable.

Understanding the Basics of Polishing

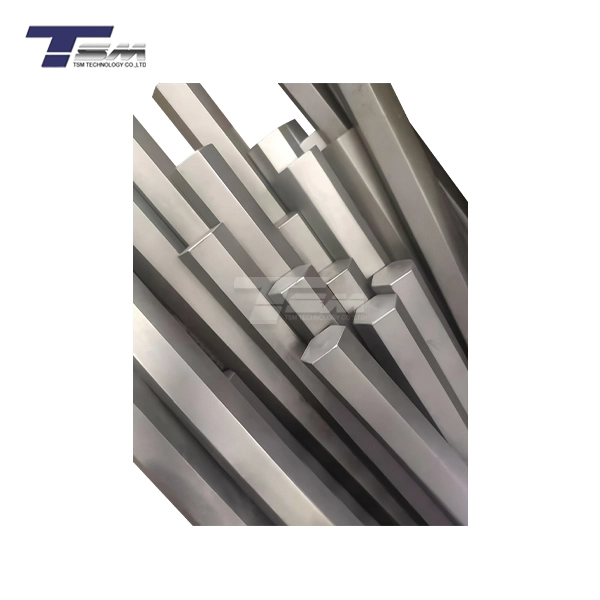

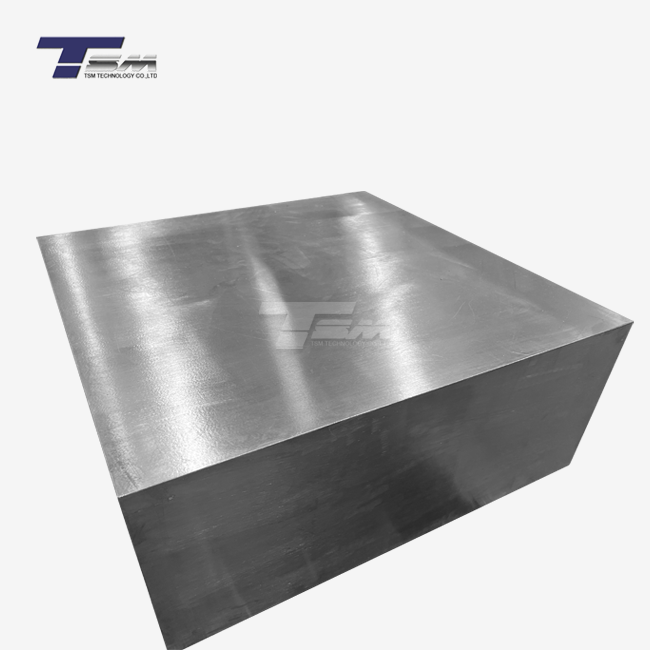

At its essence, metal polishing is the act of smoothing and refining a metal surface to achieve a desired finish. This can range from a satin sheen to a mirror-like gloss, depending on the application. For superior alloys, the process begins with selecting the right abrasive tools and compounds. These alloys, known for their exceptional resistance to heat and corrosion, require specialized techniques to preserve their inherent properties. The goal is to remove imperfections - such as scratches, burrs, or oxidation - while maintaining the material's structural integrity. Polishing isn't just cosmetic; it also reduces friction, enhances cleanability, and prepares the metal for further treatments like coating or welding.

The Role of Abrasives in Achieving Perfection

Abrasives play a vital role in the polishing process. These materials, ranging from coarse grits to ultra-fine powders, systematically wear down surface irregularities. For superior alloys, the choice of abrasive is crucial. Harder alloys like Inconel alloy demand diamond-based abrasives, which can tackle their robust composition without causing undue wear to tools. The process typically progresses through multiple stages, starting with coarse abrasives to remove deep imperfections and gradually moving to finer grits for a polished finish. Each stage requires precision, as over-polishing can compromise the alloy's surface, while under-polishing leaves it vulnerable to environmental damage. This balance is where expertise and quality control shine, ensuring every piece meets exacting standards.

Chemical Treatments and Their Impact

Beyond mechanical abrasives, chemical treatments play a pivotal role in polishing superior alloys. These treatments, often involving passivation or electropolishing, enhance the metal's surface at a microscopic level. Passivation, commonly used for alloys like Hastelloy, removes surface contaminants and bolsters corrosion resistance by forming a protective oxide layer. Electropolishing, on the other hand, uses an electrochemical process to dissolve microscopic peaks on the metal surface, resulting in an ultra-smooth, reflective finish. These methods are particularly vital for industries like aerospace and marine, where superior alloys must withstand harsh conditions. By combining mechanical and chemical techniques, manufacturers achieve a finish that's both functional and visually stunning.

Polishing Techniques Tailored for Superior Alloys

Not all metals are created equal, and superior alloys demand a bespoke approach to polishing. These advanced materials, prized for their resilience and versatility, require techniques that preserve their unique properties while delivering a flawless finish.

Adapting Techniques for High-Performance Alloys

Superior alloys like Monel and Incoloy are engineered for extreme conditions, from deep-sea exploration to high-temperature industrial furnaces. Polishing these materials requires a nuanced understanding of their composition. Monel, a nickel-copper alloy, is notoriously tough and resistant to corrosion, making it ideal for marine applications. Polishing Monel often involves a combination of vibratory finishing and manual buffing to achieve a uniform sheen without compromising its protective qualities. Incoloy, known for its heat resistance, requires careful control of polishing temperatures to prevent surface hardening or cracking. These tailored techniques ensure that the alloys retain their performance characteristics while meeting aesthetic and functional requirements.

Precision Polishing for Complex Shapes

Superior alloys are often supplied in intricate shapes - think tubes, fittings, or precision-machined components. Polishing these complex geometries poses a unique challenge. Traditional methods like belt sanding are impractical for tight corners or curved surfaces, so manufacturers turn to advanced techniques like centrifugal barrel finishing. This method uses high-speed rotation to tumble the metal parts with abrasive media, ensuring every nook and cranny is polished to perfection. For components destined for precision engineering, such as those supplied by TSM TECHNOLOGY, this level of detail is essential. The result is a component that not only performs flawlessly but also looks impeccable, reflecting the quality of the craftsmanship behind it.

Quality Control in Polishing Superior Alloys

The polishing process for superior alloys is only as good as the quality control measures in place. At TSM TECHNOLOGY, every polished piece undergoes rigorous inspection by professional inspectors to ensure it meets global standards. Surface profilometers measure roughness at a microscopic level, while visual inspections check for uniformity and defects. For alloys like Hastelloy, additional tests assess corrosion resistance post-polishing, ensuring the material's protective properties remain intact. This meticulous approach to quality control is what sets superior alloy suppliers apart, guaranteeing that every polished component is ready for the most demanding applications. It's a testament to the dedication to excellence that defines the industry.

The Impact of Polishing on Performance and Longevity

Polishing isn't just about aesthetics; it's a critical factor in the performance and longevity of superior alloys. A well-polished surface can make the difference between a component that lasts decades and one that fails prematurely.

Enhancing Corrosion Resistance

Superior alloys are prized for their ability to withstand corrosive environments, but polishing takes this resistance to the next level. A smooth, polished surface minimizes crevices where corrosive agents like saltwater or acidic chemicals can accumulate. For alloys like Monel alloy, used extensively in marine environments, this is a game-changer. Polishing also facilitates passivation, a process that strengthens the alloy's natural oxide layer, further bolstering its defenses against rust and degradation. In industries where downtime due to corrosion is costly, such as oil and gas, the role of polishing in extending service life cannot be overstated. It's an investment in reliability and performance.

Improving Mechanical Performance

The benefits of polishing extend beyond corrosion resistance to mechanical performance. A polished surface reduces friction, which is critical for components like valves, fittings, and fasteners made from superior alloys. Lower friction means less wear and tear, translating to longer operational life and reduced maintenance costs. In high-temperature applications, such as those using Inconel, a polished surface can also mitigate thermal stress by ensuring even heat distribution. This is particularly important in aerospace, where precision and reliability are paramount. By enhancing mechanical properties, polishing ensures that superior alloys deliver on their promise of exceptional performance, even under the most grueling conditions.

Elevating Aesthetic and Functional Value

While performance is king, aesthetics matter too, especially in industries where visible components reflect a brand's commitment to quality. A polished superior alloy component, whether it's a gleaming Incoloy fitting or a flawless Hastelloy tube, exudes professionalism and precision. This visual appeal is more than skin deep - it also enhances functionality. Polished surfaces are easier to clean, making them ideal for hygienic applications in pharmaceuticals or food processing. They also improve weldability and coating adhesion, ensuring that subsequent manufacturing steps are seamless. In essence, polishing bridges the gap between form and function, delivering components that are as beautiful as they are robust.

Conclusion

The industrial metal polishing process is a remarkable fusion of artistry and engineering, especially when applied to superior alloys. From abrasive techniques to chemical treatments, each step is meticulously designed to enhance the material's performance, longevity, and visual appeal. For industries relying on advanced materials, such as precision engineering and aerospace, this process is indispensable. It ensures that every component, whether a corrosion-resistant Monel fitting or a heat-tolerant Inconel tube, meets the highest standards of quality and reliability. By understanding the intricacies of polishing, businesses can better appreciate the value of superior alloys in their operations.

Contact Us

For more information on superior alloy products and advanced metal finishing techniques, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you with your precision engineering needs and provide solutions tailored to your specific requirements.

References

Callister, W. D., & Rethwisch, D. G. (2018). Materials Science and Engineering: An Introduction.

Davis, J. R. (Ed.). (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Smith, W. F. (1993). Structure and Properties of Engineering Alloys.

Budinski, K. G., & Budinski, M. K. (2010). Engineering Materials: Properties and Selection.

ASM Handbook Committee. (1990). ASM Handbook, Volume 5: Surface Engineering.

Totten, G. E., & Liang, H. (Eds.). (2004). Mechanical Tribology: Materials, Characterization, and Applications.

Learn about our latest products and discounts through SMS or email