- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is Metal Pickling? Which Products Need to be Pickled?

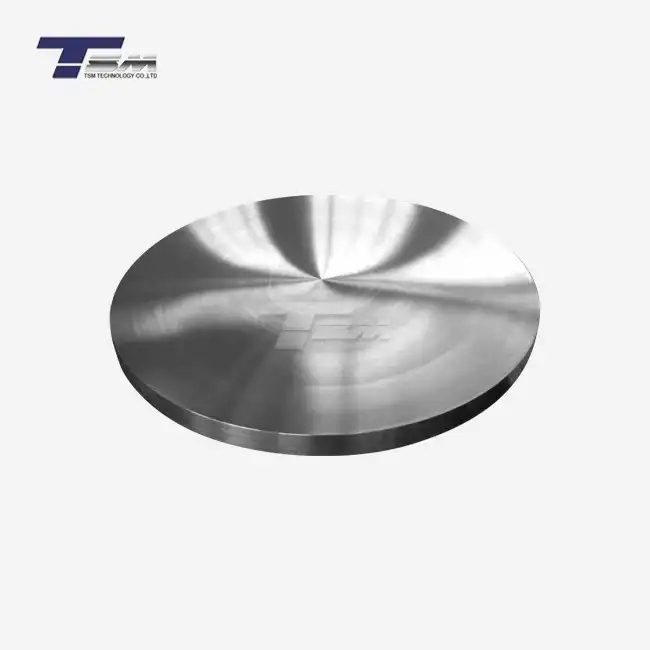

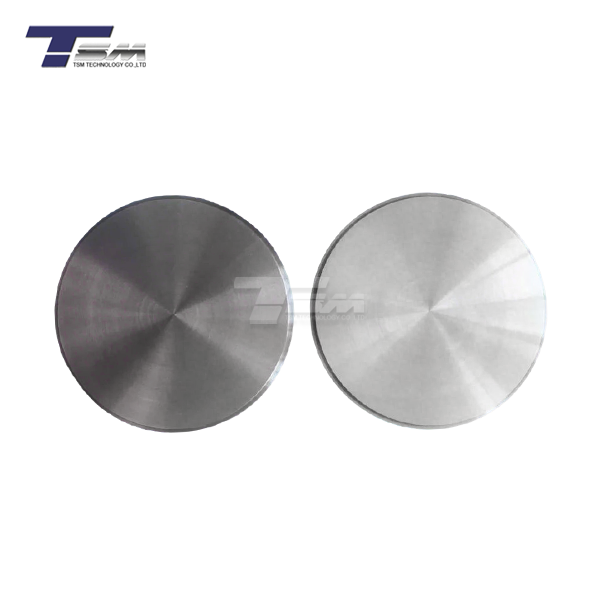

Metal pickling is a transformative process that rejuvenates metal surfaces by stripping away impurities such as rust, scale, and tarnish, leaving behind a pristine, smooth finish. This meticulous technique involves immersing metal components in specialized acid solutions to cleanse and enhance their surface quality, ensuring optimal performance and longevity. But which products benefit from this process? Items crafted from high-performance materials, such as superior alloys, often require pickling to maintain their integrity, especially in demanding industries like aerospace, oil and gas, and precision engineering. Nickel-based alloys, stainless steel, and titanium components are prime candidates, as pickling ensures they meet stringent quality standards, resist corrosion, and perform reliably in extreme conditions.

The Metal Pickling Process: Steps and Techniques

The art of metal pickling is a symphony of precision, requiring a deep understanding of materials, chemistry, and technique. This process is indispensable for industries relying on high-quality metals, especially those utilizing superior alloys.

Understanding the Chemistry of Pickling

At its heart, pickling is a chemical dance. Acidic solutions, often a blend of nitric, hydrofluoric, or sulfuric acids, are used to dissolve oxides, scale, and other surface contaminants. The choice of acid depends on the metal's composition - nickel-based alloys, such as Monel or Inconel, may require a specific formulation to avoid damaging their unique microstructure. This chemical interaction not only cleans the surface but also passivates it, forming a protective layer that enhances corrosion resistance. The precision of this step is paramount, as improper acid concentrations or exposure times can compromise the material's integrity.

Key Steps in the Pickling Process

The journey of pickling begins with surface preparation, where metals are degreased to remove oils and residues. Next, the components are submerged in the pickling bath, a carefully controlled environment where temperature, acid strength, and immersion duration are meticulously monitored. After the impurities are eradicated, the metal undergoes rinsing to neutralize residual acids, followed by drying to prevent flash corrosion. In industries dealing with advanced materials, such as superior alloys, additional steps like passivation or electropolishing may be employed to further refine the surface, ensuring it meets exacting standards for performance and aesthetics.

Techniques and Innovations in Modern Pickling

Traditional pickling methods have evolved with technological advancements, offering more efficient and environmentally conscious solutions. Spray pickling, where acid is misted onto the surface, is ideal for large or complex components, while gel pickling targets localized areas with precision. Innovations in waste management have also reduced the environmental footprint of pickling, with acid recovery systems and neutralization processes becoming standard in forward-thinking facilities. Companies specializing in high-performance alloys are at the forefront of adopting these cutting-edge techniques, ensuring their products remain competitive in a global market that demands both quality and sustainability.

Products That Require Metal Pickling

Not all metals require pickling, but for those destined for critical applications, this process is non-negotiable. Superior alloys, in particular, often undergo pickling to unlock their full potential.

Stainless Steel Components for Precision Applications

Stainless steel, while inherently corrosion-resistant, often requires pickling to enhance its performance, especially in medical, pharmaceutical, and food processing industries. During fabrication, stainless steel may develop oxide layers or surface contaminants that diminish its hygienic properties or aesthetic appeal. Pickling restores its gleaming finish and passivates the surface, ensuring it remains impervious to rust and bacterial growth. Products like surgical instruments, storage tanks, and architectural fittings benefit immensely from this process, as it guarantees both functionality and visual excellence.

Nickel-Based Alloys in High-Stress Environments

Nickel-based alloys, such as Hastelloy, Incoloy, and Monel, are celebrated for their resilience in extreme conditions, from corrosive chemical plants to scorching aerospace engines. These materials, however, are prone to surface imperfections during manufacturing, such as weld scale or heat tint. Pickling is essential to remove these blemishes, ensuring the Nickel alloys' corrosion resistance and mechanical strength remain uncompromised. Components like heat exchangers, turbine blades, and piping systems, crafted from these advanced materials, rely on pickling to meet rigorous industry standards, making it a cornerstone of quality assurance in precision engineering.

Titanium and Exotic Metals in Specialized Industries

Titanium and other exotic metals, prized for their strength-to-weight ratio and corrosion resistance, are staples in aerospace, marine, and chemical processing sectors. These materials, however, are notoriously sensitive to surface contamination, which can impair their performance in high-stakes applications. Pickling is crucial to remove scale, discoloration, and embedded impurities, ensuring these metals perform flawlessly in environments where failure is not an option. From aircraft frames to deep-sea exploration equipment, components made from these specialized materials depend on pickling to maintain their edge in demanding global markets.

Benefits and Considerations of Metal Pickling

While the pickling process is undeniably valuable, its benefits extend far beyond a clean surface. For industries relying on superior alloys, understanding the advantages and nuances of pickling is key to maximizing product quality and operational efficiency.

Enhancing Performance and Longevity

The primary allure of pickling lies in its ability to elevate a metal's performance. By eradicating surface impurities, pickling enhances corrosion resistance, a vital attribute for alloys deployed in harsh environments, such as offshore oil rigs or chemical reactors. This process also improves fatigue resistance, extending the lifespan of components subjected to cyclic stresses, like those in aerospace or automotive applications. For manufacturers of high-performance alloys, pickling is not just a finishing step - it's a strategic investment in product durability and reliability, ensuring their materials stand the test of time in global markets.

Aesthetic and Functional Improvements

Beyond performance, metal pickling delivers aesthetic enhancements that are equally important in certain industries. A polished, uniform surface is essential for architectural panels, medical devices, and consumer goods, where visual appeal can influence market perception. Functionally, a pickled surface facilitates better adhesion for coatings, welds, and other secondary processes, ensuring seamless integration into complex assemblies. In precision engineering, where every detail matters, the dual benefits of aesthetics and functionality make pickling an indispensable part of the manufacturing workflow, particularly for advanced materials like nickel-based alloys.

Environmental and Safety Considerations

While pickling offers myriad benefits, it's not without challenges. The use of potent acids necessitates stringent safety protocols to protect workers and the environment. Modern facilities mitigate these risks through closed-loop systems, acid recycling, and rigorous waste treatment, aligning with global sustainability goals. Companies specializing in superior alloys are increasingly adopting these practices, not only to comply with regulations but also to enhance their reputation as responsible innovators. When selecting a pickling process, it's crucial to balance efficacy with environmental stewardship, ensuring that the pursuit of quality doesn't come at the expense of ecological integrity.

Conclusion

Metal pickling is a cornerstone of quality assurance in industries that demand excellence from their materials. By cleansing and enhancing the surfaces of superior alloys, this process ensures that products meet the exacting standards of performance, durability, and aesthetics required in precision engineering and beyond. From nickel-based alloys to titanium components, pickling unlocks the full potential of advanced materials, making it an essential step in delivering reliable solutions to global markets. As industries evolve, so too does the art of pickling, with innovations paving the way for more sustainable and efficient practices.

Contact Us

For more information about superior nickel alloys and special metals, including products that may benefit from pickling processes, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right materials for your specific needs and ensuring optimal performance in your applications.

References

ASM International, "Surface Engineering for Corrosion and Wear Resistance," Materials Park, OH, 2001.

Nickel Institute, "Guidelines for the Use of Nickel-Based Alloys in Corrosive Environments," Toronto, Canada, 2018.

ASTM International, "Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems," ASTM A380, West Conshohocken, PA, 2017.

European Stainless Steel Development Association, "Pickling and Passivation of Stainless Steel," Brussels, Belgium, 2015.

International Titanium Association, "Surface Treatment of Titanium and Titanium Alloys," Denver, CO, 2019.

Society of Manufacturing Engineers, "Advanced Surface Finishing Techniques for High-Performance Alloys," Dearborn, MI, 2020.

Learn about our latest products and discounts through SMS or email