Understanding Inconel 600 and Its Properties

Composition and Characteristics of Inconel 600

Inconel 600 is a nickel-chromium alloy renowned for its exceptional resistance to corrosion and heat. Its composition typically includes 72% nickel, 14-17% chromium, and 6-10% iron, along with trace amounts of other elements. This unique blend imparts remarkable properties to Inconel 600 tubing, making it a preferred choice for applications requiring high temperature and corrosion resistance.

Applications of Inconel 600 Pipes and Tubes

The versatility of Inconel 600 pipes extends across various industries. In the chemical processing sector, Inconel 600 tubing is used for heat exchangers and reaction vessels. The nuclear industry relies on Inconel 600 for steam generator tubes and other critical components. Aerospace applications include exhaust systems and engine components where high-temperature strength is paramount.

Importance of Corrosion Resistance in Inconel 600

Corrosion resistance is a defining feature of Inconel 600 alloy. This property is crucial in environments where exposure to aggressive chemicals, high temperatures, and oxidizing conditions is common. The ability of Inconel 600 tubes to withstand these harsh conditions ensures longer service life and improved safety in critical applications.

Intergranular Corrosion: Mechanisms and Impacts

Definition and Causes of Intergranular Corrosion

Intergranular corrosion is a localized form of corrosion that occurs along the grain boundaries of a metal. In Inconel 600 tubing, this phenomenon can be triggered by the precipitation of chromium carbides at grain boundaries during heat treatment or welding processes. This precipitation depletes the surrounding areas of chromium, making them more susceptible to corrosive attack.

Effects of Intergranular Corrosion on Inconel 600 Performance

The impact of intergranular corrosion on Inconel 600 pipes can be severe. It can lead to a significant reduction in mechanical strength, ductility, and overall structural integrity. In extreme cases, it may result in the complete failure of Inconel 600 components, potentially causing safety hazards and operational disruptions in critical systems.

Factors Influencing Intergranular Corrosion Susceptibility

Several factors can influence the susceptibility of Inconel 600 tubing to intergranular corrosion. These include the alloy's heat treatment history, operating temperature, environmental conditions, and stress state. Understanding these factors is crucial for implementing effective prevention strategies and conducting accurate intergranular corrosion testing.

Intergranular Corrosion Testing Methods for Inconel 600 Tube

ASTM G28 Method: Procedure and Interpretation

The ASTM G28 method is a widely used standard for testing the intergranular corrosion resistance of Inconel 600 pipes. This test involves exposing samples to a boiling ferric sulfate-sulfuric acid solution for 120 hours. After the exposure, the samples are examined for weight loss and microstructural changes. The extent of intergranular attack is assessed through metallographic examination of cross-sections.

Huey Test: Application to Inconel 600 Tubing

The Huey test, another important method for evaluating intergranular corrosion in Inconel 600 tubes, involves repeated boiling of samples in nitric acid. This test is particularly useful for assessing the corrosion resistance of Inconel 600 in oxidizing environments. The test typically consists of five 48-hour periods of exposure, with weight loss measurements taken after each period.

Advanced Techniques: Electrochemical Potentiokinetic Reactivation (EPR) Testing

EPR testing is an advanced electrochemical technique used to quantify the degree of sensitization in Inconel 600 alloy. This non-destructive method provides rapid results and can detect even slight changes in the material's susceptibility to intergranular corrosion. EPR testing is particularly valuable for in-situ assessment of Inconel 600 pipes and tubes in operational environments.

Conclusion

Intergranular corrosion testing of Inconel 600 tube is a crucial process in ensuring the reliability and longevity of components made from this high-performance alloy. Through various testing methods such as ASTM G28, the Huey test, and advanced electrochemical techniques, manufacturers and end-users can accurately assess the material's resistance to this insidious form of corrosion. Understanding the mechanisms of intergranular corrosion and implementing rigorous testing protocols are essential steps in maximizing the performance and safety of Inconel 600 pipes and tubes across diverse industrial applications.

FAQs

What is the primary cause of intergranular corrosion in Inconel 600 tubes?

The primary cause is the precipitation of chromium carbides at grain boundaries, depleting surrounding areas of chromium and making them susceptible to corrosive attack.

How does the ASTM G28 method test for intergranular corrosion in Inconel 600 pipes?

The ASTM G28 method exposes Inconel 600 samples to a boiling ferric sulfate-sulfuric acid solution for 120 hours, followed by weight loss measurement and microstructural examination.

Why is intergranular corrosion testing important for Inconel 600 tubing?

Testing is crucial to ensure the reliability and safety of Inconel 600 components, particularly in critical applications within industries like chemical processing, nuclear power, and aerospace.

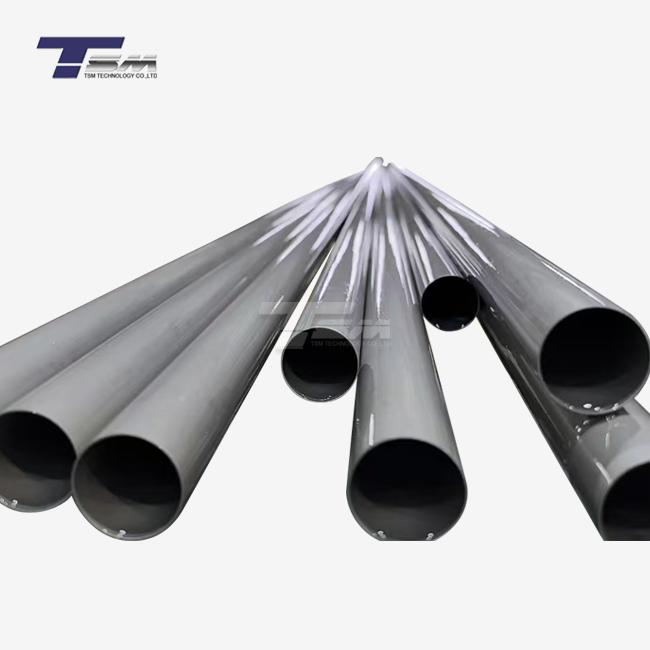

High-Quality Inconel 600 Tubes for Sale | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing and supplying premium Inconel 600 tubes. Our state-of-the-art facilities and strict quality control processes ensure superior performance, durability, and consistency for all our products. Whether you need standard sizes or custom specifications, our expert team is ready to provide tailored solutions to meet your requirements. Contact us at info@tsmnialloy.com to learn more about our high-quality Inconel 600 tubes and place your order today.

References

ASTM International. (2019). "Standard Test Methods for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels." ASTM G28-02.

Special Metals Corporation. (2018). "Inconel alloy 600 Technical Data Sheet."

Kowaka, M., & Nagano, H. (1974). "Intergranular Stress Corrosion Cracking of Inconel 600 in High Temperature Water." Corrosion, 30(2), 42-48.

Was, G. S., & Bruemmer, S. M. (1994). "Effects of irradiation on intergranular stress corrosion cracking." Journal of Nuclear Materials, 216, 326-347.

Staehle, R. W. (1992). "Understanding 'situation-dependent strength': A fundamental objective in assessing the history of stress corrosion cracking." In Environment-Induced Cracking of Metals (pp. 561-612). NACE International.

Rebak, R. B., & Szklarska-Smialowska, Z. (1996). "The mechanism of stress corrosion cracking of alloy 600 in high temperature water." Corrosion Science, 38(6), 971-988.