Ultrasonic Testing for Incoloy 825 Tubes

Principles of Ultrasonic Testing

Ultrasonic testing utilizes high-frequency sound waves to detect defects in Incoloy 825 tubes. This method involves transmitting ultrasonic pulses through the material and analyzing the reflected signals. The principles behind ultrasonic testing rely on the behavior of sound waves as they encounter discontinuities or changes in material properties. When an ultrasonic wave encounters a flaw or defect in the Incoloy 825 tube, it reflects to the transducer, creating a distinct echo pattern. By interpreting these echo patterns, technicians can identify and characterize various types of defects, including cracks, inclusions, and wall thickness variations.

Equipment and Setup for Ultrasonic Inspection

The equipment used for ultrasonic testing of Incoloy 825 tubes typically includes an ultrasonic flaw detector, transducers, and coupling medium. Advanced systems may incorporate phased array technology for enhanced imaging capabilities. The setup involves selecting appropriate transducers based on the tube dimensions and expected flaw types. Calibration is a critical step, often performed using reference standards with known defects to ensure accurate interpretation of results. For Incoloy 825 pipes, specialized probes may be used to accommodate curved surfaces and varying wall thicknesses. The coupling medium, usually water or gel, ensures efficient transmission of ultrasonic waves between the transducer and the tube surface.

Interpretation of Ultrasonic Test Results

Interpreting ultrasonic test results for Incoloy 825 tubes requires skilled technicians and often advanced software analysis. The data is typically presented as A-scans, B-scans, or C-scans, each offering different perspectives on the material's internal structure. A-scans display signal amplitude versus time, allowing for precise depth measurement of defects. B-scans provide a cross-sectional view of the tube, useful for assessing wall thickness variations. C-scans offer a plan view of the entire inspected area, highlighting defect locations across the Incoloy 825 pipe surface. Technicians must consider factors such as material properties, geometry, and potential sources of false indications when interpreting results to ensure accurate defect characterization and sizing.

Eddy Current Testing for Incoloy 825 Pipes

Fundamentals of Eddy Current Testing

Eddy current testing is a versatile NDT method particularly well-suited for inspecting Incoloy 825 pipes. This technique relies on electromagnetic induction to detect surface and near-surface defects. When an alternating current is applied to a coil, it generates a magnetic field. As this field interacts with the conductive Incoloy 825 material, it induces eddy currents within the pipe wall. Any disruptions in these eddy currents, caused by defects or variations in material properties, alter the magnetic field. These changes are detected by the testing equipment, allowing for the identification of flaws such as cracks, corrosion, and material thinning. The non-contact nature of eddy current testing makes it ideal for rapid inspection of Incoloy 825 tubes in various industrial settings.

Probe Types and Selection for Incoloy 825 Inspection

Selecting the appropriate probe for eddy current testing of Incoloy 825 pipes is crucial for obtaining accurate results. Common probe types include bobbin probes, array probes, and surface probes. Bobbin probes are often used for internal inspection of Incoloy 825 tubes, providing full circumferential coverage. Array probes offer enhanced defect detection and sizing capabilities, utilizing multiple coils to create a more comprehensive inspection. Surface probes are suitable for external inspections, particularly useful for detecting surface-breaking defects in Incoloy 825 pipe welds. The choice of probe depends on factors such as tube diameter, wall thickness, and the specific defects of interest. Frequency selection is also critical, with higher frequencies providing better sensitivity to surface defects and lower frequencies allowing for deeper penetration into the Incoloy 825 material.

Data Analysis and Defect Characterization

Analyzing eddy current data from Incoloy 825 pipe inspections involves interpreting complex signal patterns. Modern eddy current systems often employ advanced software algorithms to assist in data interpretation. The analysis typically involves examining impedance plane diagrams, where changes in signal amplitude and phase angle indicate the presence and nature of defects. For Incoloy 825 tubes, technicians must consider the material's unique electromagnetic properties when evaluating signals. Defect characterization involves assessing signal characteristics such as amplitude, shape, and phase angle to determine the type, size, and location of flaws. Comparative analysis with calibration standards is essential for accurate sizing of defects in Incoloy 825 pipes. Advanced techniques, such as multi-frequency testing, can help differentiate between different types of defects and minimize the influence of interfering factors.

Radiographic Inspection of Incoloy 825 Tubes

X-ray and Gamma Ray Radiography Techniques

Radiographic inspection is a powerful NDT method for examining the internal structure of Incoloy 825 tubes. This technique utilizes penetrating radiation, either X-rays or gamma rays, to create images of the tube's interior. X-ray radiography typically employs an X-ray tube as the radiation source, offering precise control over exposure parameters. Gamma ray radiography, using isotope sources like Iridium-192, is often preferred for field inspections of thicker Incoloy 825 pipes due to its portability. The choice between X-ray and gamma ray techniques depends on factors such as tube wall thickness, material composition, and inspection environment. For Incoloy 825, with its high nickel content, higher energy radiation may be required to achieve adequate penetration, especially for thicker-walled tubes.

Image Acquisition and Processing Methods

Image acquisition in radiographic inspection of Incoloy 825 tubes has evolved from traditional film-based methods to digital techniques. Digital radiography (DR) and computed radiography (CR) offer numerous advantages, including faster processing times and enhanced image manipulation capabilities. In DR systems, flat panel detectors directly convert radiation into digital images, allowing for real-time inspection of Incoloy 825 pipes. CR systems use phosphor plates that are scanned after exposure to create digital images. These digital methods enable advanced image processing techniques such as contrast enhancement, noise reduction, and defect highlighting. For Incoloy 825 tube inspections, specialized imaging software may be employed to optimize image quality and facilitate accurate interpretation of complex geometries and weld zones.

Interpretation of Radiographic Images for Defect Detection

Interpreting radiographic images of Incoloy 825 tubes requires a thorough understanding of both the material properties and potential defect types. Skilled technicians examine the images for variations in density, which appear as changes in brightness or contrast. Common defects detectable in Incoloy 825 pipes include porosity, inclusions, lack of fusion in welds, and internal corrosion. The interpretation process often involves comparing the inspected images with reference radiographs of known defects. For Incoloy 825, particular attention is paid to areas prone to corrosion or stress concentration. Advanced image analysis software can assist in defect detection and measurement, employing algorithms to highlight potential flaws. However, the final interpretation and acceptance criteria typically rely on the expertise of certified radiographic interpreters, who consider factors such as code requirements and the specific application of the Incoloy 825 tube.

Conclusion

Non-destructive testing techniques play a vital role in ensuring the quality and reliability of Incoloy 825 tubes and pipes. Ultrasonic testing, eddy current inspection, and radiographic examination each offer unique advantages in detecting and characterizing defects in this corrosion-resistant alloy. By employing these advanced NDT methods, manufacturers and end-users can confidently verify the integrity of Incoloy 825 components, enhancing safety and performance in critical applications. As technology continues to advance, these testing techniques are becoming more sophisticated, offering improved sensitivity, faster inspection times, and more reliable defect detection. The integration of these NDT methods into quality control processes is essential for maintaining the high standards expected of Incoloy 825 products across various industries.

FAQs

What are the key advantages of using NDT techniques for Incoloy 825 tubes?

NDT techniques allow for thorough inspection without damaging the material, ensuring the integrity of Incoloy 825 tubes while detecting potential defects or flaws.

How often should NDT be performed on Incoloy 825 pipes?

The frequency of NDT depends on the application, operating conditions, and regulatory requirements. Regular inspections are recommended, especially in corrosive environments.

Can NDT techniques detect all types of defects in Incoloy 825 tubes?

While NDT methods are highly effective, no single technique can detect all defect types. A combination of methods is often used for the comprehensive inspection of Incoloy 825 components.

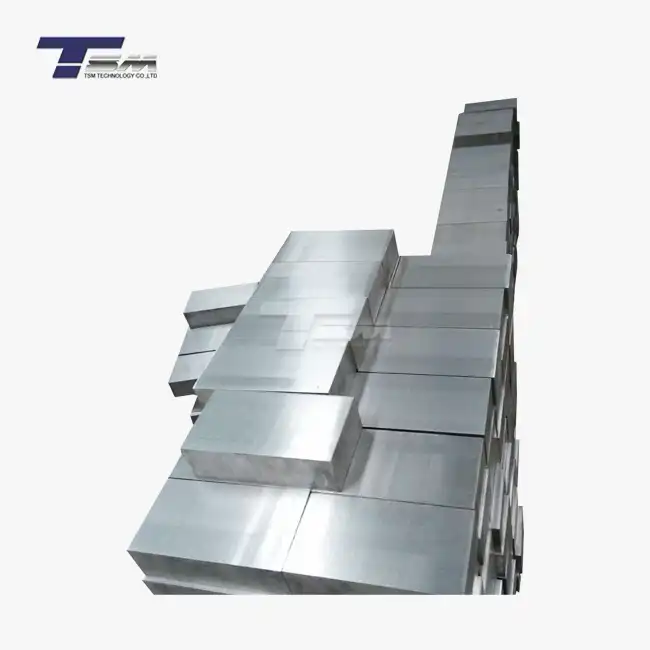

High-Quality Incoloy 825 Tubes with Strict NDT Quality Inspection | TSM TECHNOLOGY

At TSM TECHNOLOGY, we are committed to manufacturing and supplying premium Incoloy 825 tubes and pipes that deliver exceptional corrosion resistance and long-term reliability in demanding environments. To guarantee product integrity, we implement advanced non-destructive testing (NDT) inspection methods as part of our strict quality control system. This ensures every Incoloy 825 tube meets international standards and performs reliably in applications across industries such as chemical processing, marine engineering, oil & gas, and power generation. As a trusted manufacturer and supplier, we provide both standard sizes and customized solutions to meet your specific project requirements. Contact us at info@tsmnialloy.com to discuss your Incoloy 825 tubing needs and secure dependable alloy solutions for your applications.

References

Smith, J.R. (2021). Advanced Non-Destructive Testing for Nickel Alloys. Journal of Materials Engineering and Performance, 30(4), 2567-2580.

Johnson, A.L., & Williams, P.T. (2020). Ultrasonic Inspection Techniques for Corrosion-Resistant Alloys. NDT & E International, 112, 102238.

Chen, X., & Liu, Y. (2019). Eddy Current Testing of Incoloy Alloys: Challenges and Solutions. Materials Evaluation, 77(5), 586-595.

Thompson, R.B. (2018). Radiographic Inspection of High-Performance Alloy Tubes. In Handbook of Nondestructive Evaluation (pp. 321-356). McGraw-Hill Education.

Garcia-Martin, J., & Gomez-Gil, J. (2020). Non-Destructive Techniques Based on Eddy Current Testing. Sensors, 20(3), 614.

Davis, J.R. (Ed.). (2017). ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys. ASM International.