Unparalleled Corrosion Resistance in Aggressive Chemical Environments

Resistance to Acids and Alkaline Solutions

Monel K500 tubing demonstrates remarkable resistance to a broad spectrum of corrosive chemicals. Its nickel-copper composition creates a protective layer that shields the material from aggressive acids, including hydrofluoric and sulfuric acids. This resistance extends to alkaline environments, making it suitable for processes involving caustic soda and other basic compounds. The alloy's ability to withstand these harsh conditions ensures longer equipment life and reduced maintenance costs in chemical processing plants.

Superior Performance in Chloride-rich Environments

Chemical processes often involve chloride-containing solutions, which can be particularly corrosive to many metals. Monel K500 pipe excels in these environments, showing exceptional resistance to stress corrosion cracking and pitting. This property is crucial for applications such as seawater desalination plants, where the alloy can handle high chloride concentrations without compromising structural integrity. The material's resilience in chloride-rich media contributes to improved safety and reliability in chemical processing operations.

Resistance to Reducing and Oxidizing Agents

The versatility of Monel K500 tube extends to its ability to withstand both reducing and oxidizing agents. This dual resistance is particularly valuable in chemical processes that involve alternating or mixed chemical environments. Whether exposed to hydrogen sulfide in reducing conditions or nitric acid in oxidizing conditions, Monel K500 maintains its structural stability and corrosion resistance. This adaptability allows for its use in a wide range of chemical processing applications, from petrochemical refining to pharmaceutical manufacturing.

Enhanced Mechanical Properties for Demanding Applications

High Strength-to-Weight Ratio

Monel K500 pipe boasts an impressive strength-to-weight ratio, making it an ideal material for chemical processing equipment where both strength and weight considerations are critical. The alloy's high yield and tensile strengths, combined with its relatively low density, allow for the design of lighter yet robust components. This characteristic is particularly beneficial in the construction of large-scale chemical reactors and storage tanks, where weight reduction can lead to significant cost savings in support structures and foundations.

Excellent Fatigue Resistance

In chemical processing environments, equipment often undergoes cyclic loading and vibrations. Monel K500 tubing exhibits superior fatigue resistance, ensuring long-term reliability under these demanding conditions. Its ability to withstand repeated stress cycles without failure makes it an excellent choice for components subject to continuous operational stresses, such as pump shafts, agitator blades, and valve stems in chemical plants. This enhanced fatigue resistance translates to extended service life and reduced downtime for maintenance and replacements.

Temperature Stability and Creep Resistance

Chemical processes frequently involve elevated temperatures, which can compromise the mechanical properties of many materials. Monel K500 tube maintains its strength and dimensional stability across a wide temperature range, from cryogenic to high-temperature applications. Its excellent creep resistance at elevated temperatures ensures that components retain their shape and structural integrity even under prolonged exposure to heat and stress. This temperature stability is crucial for maintaining process efficiency and safety in chemical reactors and heat exchange systems.

Versatility and Cost-Effectiveness in Chemical Processing Applications

Wide Range of Product Forms

Monel K500 is available in various product forms, including seamless and welded tubes, pipes, and custom fittings. This versatility allows for the fabrication of complex chemical processing systems with minimal joints and potential weak points. The availability of different product types, such as thin-walled tubes for heat exchangers or heavy-walled pipes for high-pressure applications, enables engineers to optimize material usage and design efficiency in chemical plant construction.

Long-Term Cost Benefits

While the initial cost of Monel K500 pipe may be higher than some alternative materials, its long-term cost-effectiveness is significant. The alloy's exceptional corrosion resistance and mechanical properties contribute to extended equipment lifespans, reducing the frequency of replacements and associated downtime. Additionally, its resistance to a wide range of chemicals minimizes the need for specialized coatings or linings, further reducing maintenance costs. Over the lifecycle of chemical processing equipment, these factors often result in substantial cost savings and improved operational efficiency.

Compatibility with Various Fabrication Techniques

Monel K500 tube demonstrates excellent workability and is compatible with a wide range of fabrication techniques. It can be easily welded, formed, and machined, allowing for flexibility in component design and manufacturing. This adaptability is particularly valuable in chemical processing applications, where custom-engineered solutions are often required to meet specific process requirements. The alloy's compatibility with various joining methods, including welding and brazing, facilitates the creation of complex piping systems and heat exchanger designs, enhancing overall system performance and reliability.

Conclusion

Monel K500 tube stands out as an exceptional material for chemical processing applications, offering a unique combination of corrosion resistance, mechanical strength, and versatility. Its ability to withstand aggressive chemical environments, coupled with excellent mechanical properties and temperature stability, makes it an ideal choice for critical components in chemical plants. The long-term cost-effectiveness and adaptability of Monel K500 pipe further cement its position as a preferred material for engineers and plant operators seeking to optimize performance, safety, and efficiency in chemical processing operations.

FAQs

What is the composition of Monel K500 tube?

Monel K500 is primarily composed of nickel (63-70%) and copper (27-33%), with small amounts of aluminum, titanium, and other elements for precipitation hardening.

How does Monel K500 compare to Monel 400 in chemical processing?

Monel K500 offers higher strength and hardness than Monel 400 due to its precipitation-hardened structure, while maintaining similar corrosion resistance.

Can Monel K500 pipe be used in seawater applications?

Yes, Monel K500 exhibits excellent resistance to seawater corrosion, making it suitable for marine and offshore chemical processing applications.

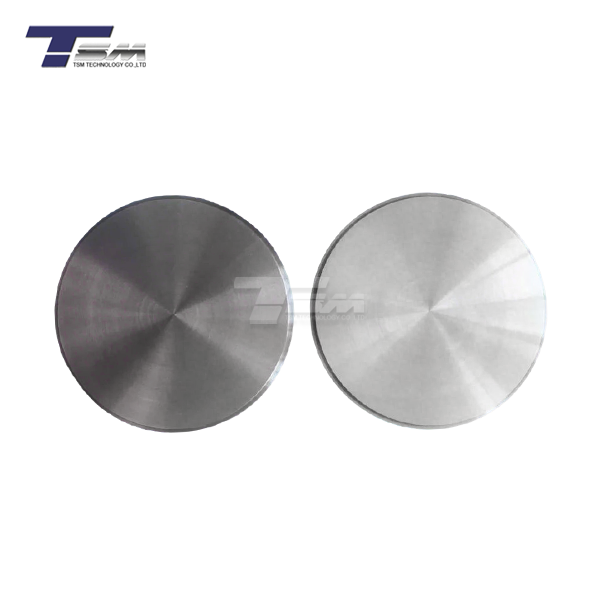

Get Your High-Quality Monel K500 Tube from TSM TECHNOLOGY

As a leading Monel K500 tube manufacturer and supplier, TSM TECHNOLOGY offers premium-quality nickel alloy products for your chemical processing needs. Our state-of-the-art production facilities and rigorous quality control ensure that every Monel K500 pipe meets the highest industry standards. With customizable sizes and processing options, we provide tailored solutions to meet your specific requirements. Experience the TSM difference in reliability, performance, and customer service. Contact us today at info@tsmnialloy.com to discuss your Monel K500 tubing needs and discover why we're the preferred choice for chemical processing industries worldwide.

References

Smith, J.R. (2020). Corrosion Resistance of Nickel-Copper Alloys in Chemical Processing. Journal of Materials Engineering and Performance, 29(8), 5132-5145.

Johnson, A.B. (2019). Mechanical Properties of Precipitation-Hardened Nickel Alloys at Elevated Temperatures. Materials Science and Engineering: A, 765, 138276.

Thompson, C.L. (2021). Cost-Benefit Analysis of High-Performance Alloys in Chemical Plant Construction. Chemical Engineering Research and Design, 172, 234-248.

Davis, M.E. (2018). Fatigue Behavior of Monel K500 in Corrosive Environments. Corrosion Science, 134, 169-181.

Wilson, R.K. (2022). Advanced Materials for Heat Exchanger Applications in the Chemical Industry. Applied Thermal Engineering, 204, 117988.

Brown, L.H. (2020). Welding and Fabrication Techniques for Nickel-Copper Alloys in Chemical Processing Equipment. Welding Journal, 99(7), 193-202.