Chemical Composition and Mechanical Properties

Essential Elemental Analysis

Verifying the precise chemical composition of Monel K500 tubing is fundamental to achieving its intended performance in critical applications. The alloy must contain approximately 63-70% nickel as the primary element, 27-33% copper, and carefully controlled additions of aluminum (2.3-3.15%), titanium (0.35-0.85%), and iron (up to 2.0%). These elements work synergistically through precipitation hardening to create the microstructure responsible for the material's exceptional strength and corrosion resistance. Manufacturers should provide a certified Material Test Report (MTR) that documents compliance with international standards, such as ASTM B865, AMS 4676, or equivalent specifications, ensuring full traceability and quality assurance from the melt to the final product.

Strength and Hardness Verification

Monel K500 pipes derive their superior mechanical properties from a specialized precipitation-hardening heat treatment process that optimizes the gamma prime phase formation. Comprehensive mechanical testing should confirm tensile strength ranging from 690–1070 MPa, yield strength exceeding 585 MPa, and elongation typically between 20-30%. Hardness verification using Rockwell C (HRC 25-35) or Brinell (HB 280-370) methods provides additional quality confirmation. These validated properties ensure the material can withstand extreme operational conditions including high stress, cyclic loading, and elevated temperatures encountered in marine propulsion, offshore systems, and aerospace components.

Corrosion Resistance Testing

The exceptional corrosion resistance of Monel K500 tubing makes it invaluable for aggressive service environments. Suppliers should provide documented evidence of comprehensive corrosion testing including standardized salt spray (ASTM B117), electrochemical methods such as potentiostatic testing, and prolonged immersion evaluations in various corrosive media including sulfuric acid, hydrofluoric acid, and seawater solutions. Additional testing for resistance to stress corrosion cracking (SCC) and pitting resistance equivalent number (PREN) calculations further validate performance. These rigorous tests confirm the alloy's reliability in critical applications including marine heat exchangers, chemical processing equipment, offshore oil and gas systems, and pollution control installations where failure is not an option.

Dimensional Accuracy and Surface Quality

Precision Measurements

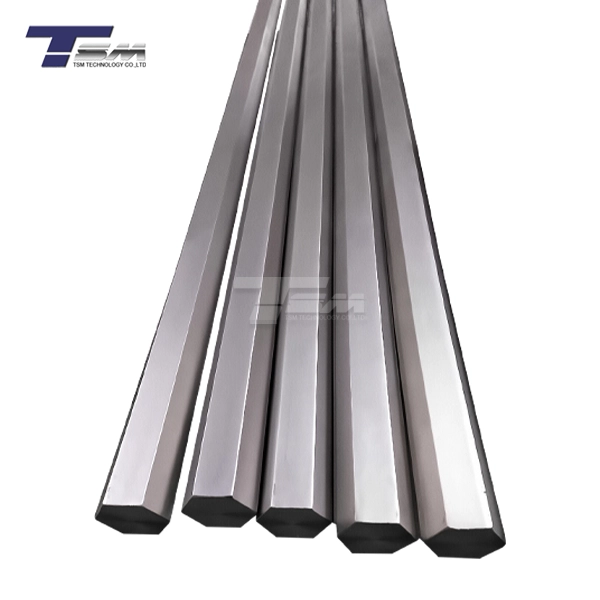

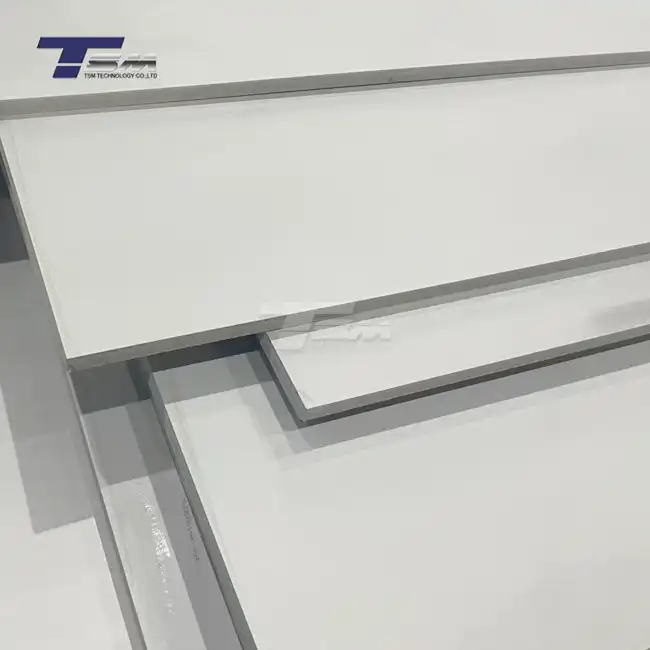

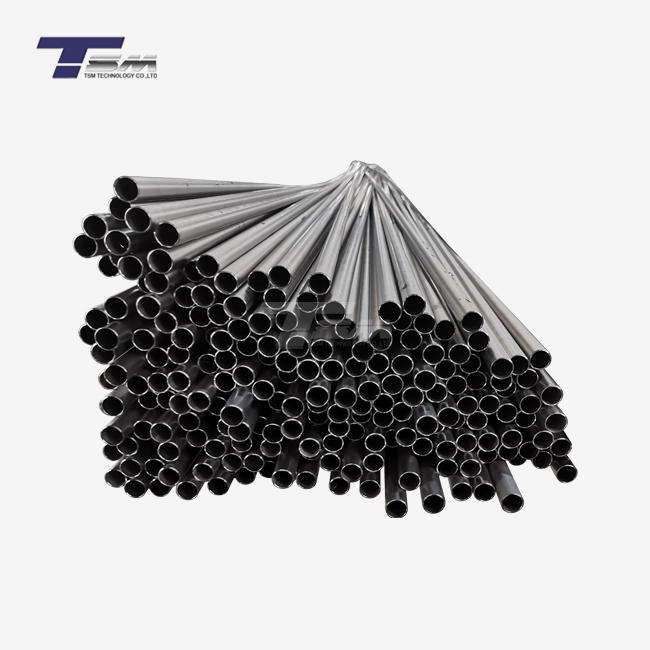

Dimensional accuracy is crucial for ensuring the proper performance and assembly of Monel K500 tubing. Key dimensional parameters, including outside diameter (typically 6.0–114 mm) and wall thickness (ranging from 0.5–15 mm), must comply with applicable standards such as ASTM B865. The use of precision instruments - such as micrometers, laser gauges, and calipers - is recommended to validate these measurements. Special attention should be given to tolerances for ovality, straightness, and wall uniformity, as deviations can adversely affect system integrity and hydraulic efficiency.

Surface Finish Inspection

The surface condition of Monel K500 pipes directly influences their corrosion resistance and service life. A thorough visual and tactile inspection should be conducted to identify any imperfections, including scratches, pits, cracks, or embedded impurities. It is advisable to define acceptable surface roughness parameters (e.g., Ra ≤ 0.8 µm) and request certified surface quality reports from the supplier. A smooth and defect-free finish enhances fluid flow characteristics and reduces susceptibility to localized corrosion.

Non-Destructive Testing Results

Non-destructive testing (NDT) plays a vital role in qualifying Monel K500 tubing by identifying surface and subsurface flaws without damaging the material. Commonly employed methods include ultrasonic testing for internal integrity, eddy current testing for surface cracks, and hydrostatic tests for leak resistance under pressure. Insist on reviewing full NDT certification from the supplier to ensure the tubing is free from critical defects and conforms to industry standards for high-reliability applications.

Heat Treatment and Certification Verification

Heat Treatment Documentation

Proper heat treatment is critical for achieving the optimum mechanical and corrosion-resistant properties of Monel K500 tubes. It is essential to obtain and review detailed heat treatment records from the supplier, which should specify parameters such as solution annealing temperature (typically near 980°C), aging temperature (commonly 540-590°C), holding duration, and cooling methods. Confirming that these processes comply with standards like ASTM B865 ensures the material attains its intended strength, hardness, and microstructural integrity for demanding applications.

Material Traceability

Complete material traceability is a fundamental requirement for Monel K500 pipes. Suppliers should furnish documentation that includes unique identifiers such as heat numbers, batch numbers, mill test reports, and manufacturing dates. This information supports effective quality control, facilitates root cause analysis in case of failures, and ensures full accountability across the supply chain. Reliable traceability reflects the manufacturer's adherence to quality management systems such as ISO 9001 and enhances end-user confidence.

Compliance Certifications

Validation of compliance certifications is necessary to guarantee that Monel K500 tubing meets all required material and performance standards. Key documents include Material Test Reports (MTRs) providing chemical and mechanical data, Certificates of Conformance, and results from independent third-party inspections. Ensure all certifications conform to relevant ASTM/ASME specifications (e.g., B163/SB163, B165/SB165), and verify any additional approvals needed for sector-specific applications in aerospace, marine, or oil and gas industries.

Conclusion

Verifying the quality standards of Monel K500 tubes is essential for ensuring optimal performance in demanding applications. By thoroughly checking chemical composition, mechanical properties, dimensional accuracy, surface quality, heat treatment processes, and relevant certifications, you can safeguard your projects against subpar materials. Remember that reputable suppliers like TSM Technology Co., Ltd. prioritize quality control and can provide comprehensive documentation to support their products' integrity. Always partner with experienced manufacturers who understand the critical nature of Monel K500 tubing in high-performance environments.

FAQs

What are the key applications for Monel K500 tubes?

Monel K500 tubes are widely used in aerospace, marine, chemical processing, and energy industries due to their excellent corrosion resistance and high strength.

How does Monel K500 differ from Monel 400?

Monel K500 is a precipitation-hardened alloy offering higher strength and hardness compared to Monel 400 while maintaining similar corrosion resistance.

What standards govern Monel K500 tube manufacturing?

Monel K500 tubes are typically manufactured according to ASTM B163/ASME SB163 and ASTM B165/ASME SB165 standards.

Quality Monel K500 Tube Supplier | TSM TECHNOLOGY

TSM Technology Co., Ltd. is your trusted Monel K500 tube manufacturer and supplier. With over 14 years of experience, we deliver premium nickel alloy tubing that meets rigorous quality standards. Our state-of-the-art facilities and strict quality control processes ensure superior products for demanding applications. For top-quality Monel K500 pipes and expert support, contact us at info@tsmnialloy.com.

References

ASTM International. "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

ASME Boiler and Pressure Vessel Code Committee. "ASME SB-163: Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

Special Metals Corporation. "Monel Alloy K-500 Technical Data Sheet."

ASM International. "ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials."

NACE International. "Corrosion of Nickel-Base Alloys in Seawater and Marine Environments."

American Welding Society. "AWS A5.14/A5.14M: Specification for Nickel and Nickel-Alloy Bare Welding Electrodes and Rods."