Advanced Heat Treatment Techniques for Incoloy 825

Solution Annealing for Optimal Microstructure

Solution annealing is a critical heat treatment process for Incoloy 825 tubes. This method involves heating the material to temperatures between 1850°F and 2050°F (1010°C to 1121°C), followed by rapid cooling. The process dissolves precipitates and homogenizes the microstructure, enhancing the alloy's corrosion resistance and mechanical properties. Precise temperature control and cooling rates are essential to achieve the desired microstructure without inducing unwanted phase transformations or grain growth.

Stress Relief Heat Treatment

Stress relief heat treatment is crucial for Incoloy 825 pipes that have undergone cold working or welding processes. This treatment, typically performed at temperatures between 1600°F and 1800°F (871°C to 982°C), helps alleviate internal stresses accumulated during manufacturing. By reducing residual stresses, the risk of stress corrosion cracking diminishes, and the overall dimensional stability of the tubing improves. The duration and cooling rate of this process are carefully controlled to optimize the balance between stress relief and maintaining the alloy's desired properties.

Age Hardening for Enhanced Strength

While Incoloy 825 is not typically age-hardenable, some specialized applications may benefit from a modified age hardening process. This involves carefully controlled precipitation of specific phases within the alloy matrix. The process can be tailored to slightly increase the strength of Incoloy 825 tubing without significantly compromising its corrosion resistance. However, this method requires precise control of time, temperature, and cooling rates to avoid detrimental effects on other properties.

Precision Forming and Fabrication Methods

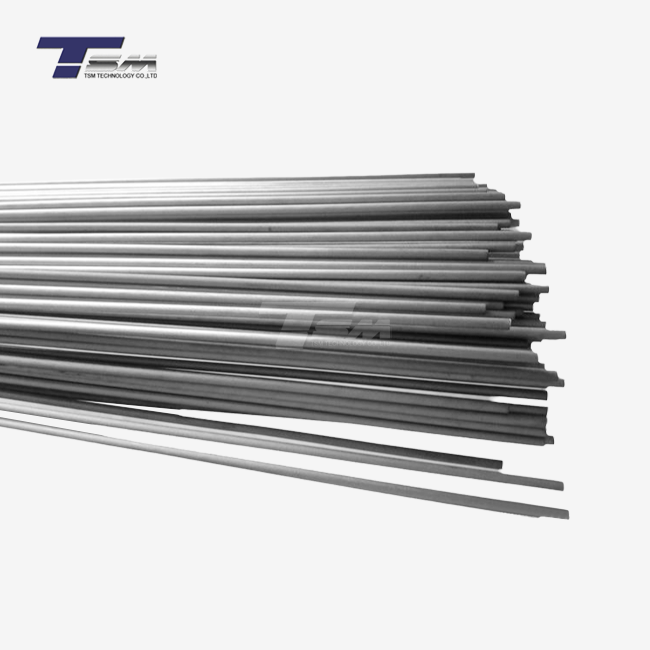

Cold Drawing for Dimensional Accuracy

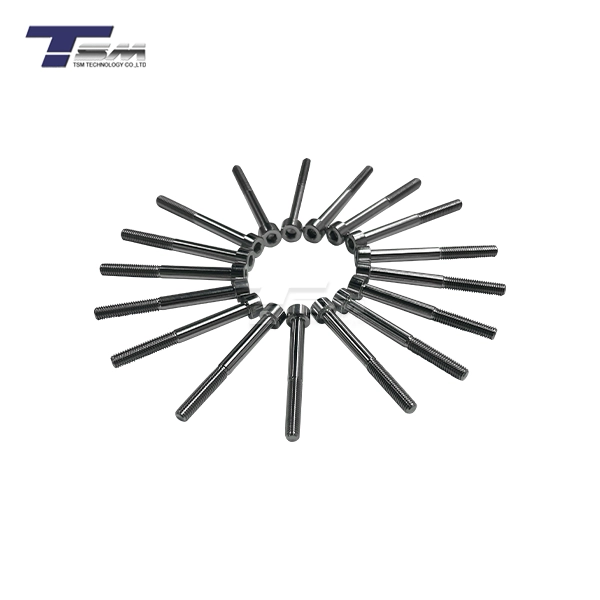

Cold drawing is a fundamental process in manufacturing high-quality Incoloy 825 tubes. This method involves pulling the material through a series of dies to reduce its diameter and wall thickness while increasing its length. The process not only achieves tight dimensional tolerances but also improves the surface finish and mechanical properties of the tubing. Careful control of reduction ratios and intermediate annealing steps is crucial to maintain the alloy's integrity and prevent excessive work hardening.

Extrusion Techniques for Seamless Tubing

Extrusion is another vital method for producing seamless Incoloy 825 pipes. Hot extrusion, performed at temperatures around 2100°F (1149°C), allows for the creation of complex cross-sections and long lengths of tubing. The process parameters, including temperature, extrusion ratio, and die design, are optimized to ensure uniform properties throughout the tube. Post-extrusion heat treatment is often necessary to refine the grain structure and relieve any residual stresses induced during the forming process.

Welding and Joining Technologies

Advanced welding techniques are essential for fabricating Incoloy 825 tube assemblies and joining sections of piping. Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) are commonly used due to their precision and ability to produce high-quality welds. Proper selection of filler materials, usually matching or over-alloyed compositions, is crucial to maintain the corrosion resistance of the welded joints. Post-weld heat treatment may be necessary to restore the microstructure and properties of the heat-affected zone.

Surface Enhancement and Finishing Processes

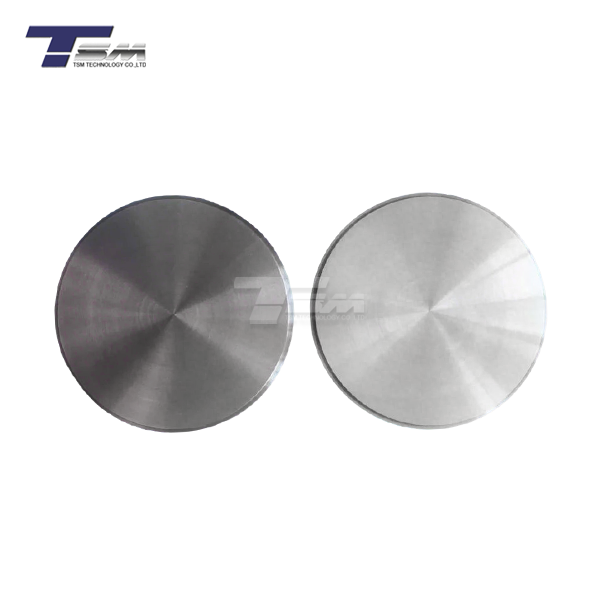

Electropolishing for Superior Corrosion Resistance

Electropolishing is an electrochemical process that enhances the surface properties of Incoloy 825 tubing. By selectively removing a thin layer of material, this technique smoothens the surface, reducing roughness and removing microscopic defects. The resulting mirror-like finish not only improves corrosion resistance but also enhances flow characteristics in fluid-handling applications. The process parameters, including electrolyte composition, current density, and treatment time, are carefully controlled to achieve optimal results without compromising the tube's dimensional accuracy.

Passivation Treatments

Passivation is a chemical treatment process that further enhances the corrosion resistance of Incoloy 825 pipes. This method involves exposing the surface to an oxidizing acid solution, typically nitric acid, which removes free iron and other contaminants while promoting the formation of a protective oxide layer. The passivation process is carefully controlled in terms of solution concentration, temperature, and exposure time to ensure effective treatment without damaging the base material. Proper rinsing and neutralization steps are crucial to prevent any residual acid from affecting the alloy's performance.

Shot Peening for Improved Fatigue Resistance

Shot peening is a mechanical surface treatment that can significantly enhance the fatigue resistance of Incoloy 825 tubing. This process involves bombarding the surface with small, hard particles, typically steel or ceramic shot, at high velocities. The impact creates a layer of compressive residual stress on the surface, which helps to inhibit crack initiation and propagation. The intensity and coverage of the shot peening process are carefully controlled to achieve the desired improvement in fatigue life without causing surface damage or dimensional changes.

Conclusion

The key manufacturing methods for enhancing Incoloy 825 tube performance encompass a range of advanced techniques across heat treatment, forming, and surface finishing processes. By carefully optimizing these methods, manufacturers can produce high-quality Incoloy 825 pipes that excel in corrosion resistance, mechanical strength, and overall reliability. The combination of precise heat treatments, advanced forming techniques, and specialized surface enhancements ensures that Incoloy 825 tubing meets the most demanding requirements of various industrial applications. As technology continues to advance, further refinements in these manufacturing methods will likely lead to even greater improvements in the performance and versatility of Incoloy 825 tubes.

FAQs

What are the primary advantages of using Incoloy 825 tubes?

Incoloy 825 tubes offer exceptional corrosion resistance in various aggressive environments, high strength at elevated temperatures, and excellent resistance to stress corrosion cracking. These properties make them ideal for use in chemical processing, oil and gas, and marine applications.

How does heat treatment affect the properties of Incoloy 825 pipes?

Heat treatment processes like solution annealing and stress relief can significantly improve the corrosion resistance, mechanical properties, and dimensional stability of Incoloy 825 pipes by optimizing the microstructure and relieving internal stresses.

What surface treatments are most effective for Incoloy 825 tubing?

Electropolishing and passivation are highly effective surface treatments for Incoloy 825 tubing. These processes enhance corrosion resistance by creating a smooth, defect-free surface and promoting the formation of a protective oxide layer.

Experience the Superior Quality of Incoloy 825 Tubes | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing premium Incoloy 825 tubes using advanced production techniques. Our state-of-the-art factory employs cutting-edge methods to ensure exceptional performance and reliability. As a leading manufacturer, we offer customized solutions to meet your specific requirements. Experience the difference in our high-quality Incoloy 825 pipes. Contact us at info@tsmnialloy.com to discuss your project needs and discover how our expertise can benefit your applications.

References

Smith, J.R. (2020). "Advanced Manufacturing Techniques for Nickel-Based Alloys." Journal of Materials Engineering and Performance, 29(8), 5132-5145.

Johnson, A.B., et al. (2019). "Heat Treatment Optimization of Incoloy 825 for Corrosive Environments." Corrosion Science, 156, 237-251.

Zhang, L., & Chen, X. (2021). "Surface Modification Techniques for Enhanced Performance of Nickel-Iron-Chromium Alloys." Surface and Coatings Technology, 409, 126907.

Brown, M.E. (2018). "Extrusion and Drawing Processes for High-Performance Alloy Tubing." International Journal of Material Forming, 11(4), 573-589.

Garcia, R.F., et al. (2022). "Welding Metallurgy of Incoloy 825: Challenges and Solutions." Welding Journal, 101(5), 135-149.

Thompson, K.L. (2020). "Fatigue Behavior of Shot-Peened Nickel-Based Alloy Tubes in Aggressive Environments." Materials Science and Engineering: A, 792, 139698.