- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

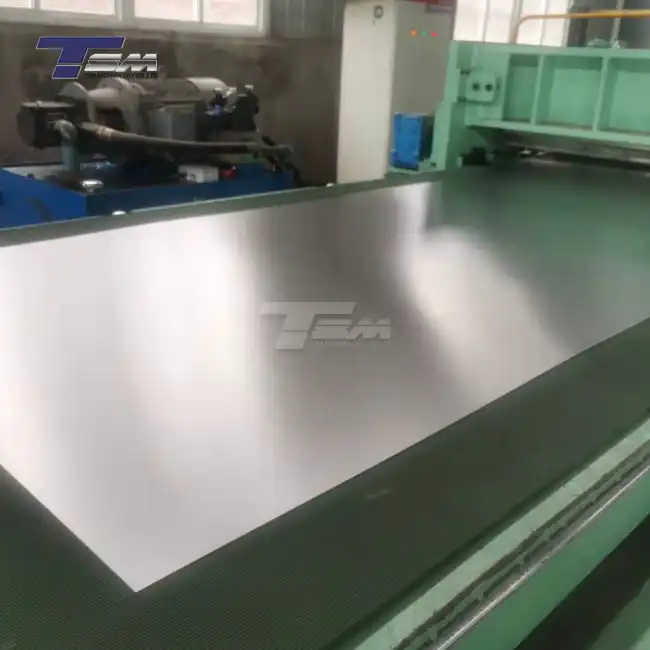

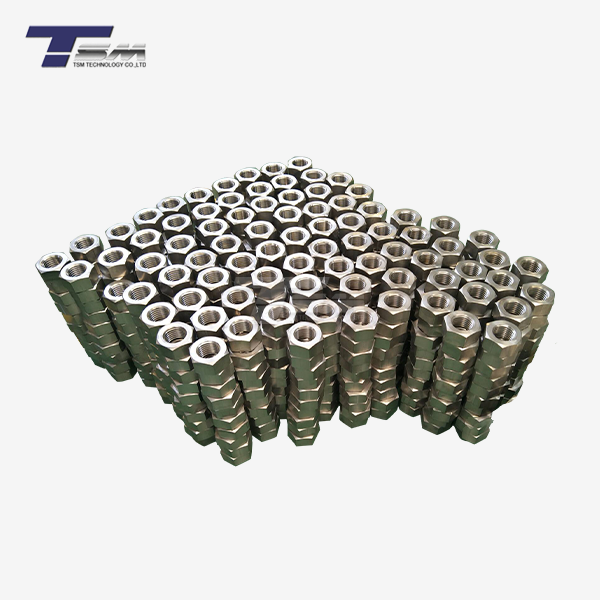

Mechanical Property Testing of Inconel 625 Sheet

Mechanical property testing of Inconel 625 sheet is a crucial process in evaluating the performance and reliability of this high-strength, corrosion-resistant nickel-chromium-based superalloy. These tests assess various characteristics such as tensile strength, yield strength, elongation, and hardness. The results provide valuable insights into the material's behavior under different conditions, ensuring its suitability for demanding applications in aerospace, marine, and chemical processing industries. Comprehensive testing helps manufacturers and engineers make informed decisions about the alloy's use in specific environments, ultimately contributing to the safety and efficiency of critical components and structures.

Understanding Inconel 625 Sheet Properties

Chemical Composition and Microstructure

Inconel 625 sheet, also known as alloy 625 sheet, is renowned for its exceptional combination of strength and corrosion resistance. The unique properties of this material stem from its carefully balanced chemical composition, which typically includes nickel (58% minimum), chromium (20-23%), molybdenum (8-10%), and niobium (3.15-4.15%). This composition results in a face-centered cubic austenitic structure, contributing to the alloy's remarkable stability across a wide range of temperatures.

The microstructure of Inconel 625 sheet plays a crucial role in determining its mechanical properties. The presence of various precipitates, such as MC carbides and Ni3Nb intermetallics, influences the material's strength and creep resistance. Understanding these microstructural features is essential for predicting and optimizing the alloy's performance in different applications.

Mechanical Characteristics

Inconel 625 sheet exhibits impressive mechanical characteristics that make it suitable for use in harsh environments. Some key properties include:

- High tensile strength (typically ranging from 120 to 150 ksi)

- Excellent yield strength (60 to 80 ksi)

- Good ductility (elongation of 30-60%)

- Impressive fatigue resistance

- Remarkable creep strength at elevated temperatures

These properties contribute to the alloy's ability to maintain its structural integrity under extreme conditions, making it a preferred choice for applications in aerospace, chemical processing, and marine industries.

Corrosion and Oxidation Resistance

One of the standout features of Inconel 625 sheet is its exceptional resistance to corrosion and oxidation. The high nickel and chromium content, combined with molybdenum and niobium, creates a protective oxide layer on the surface of the material. This layer provides excellent protection against various corrosive media, including seawater, acids, and alkaline solutions.

The alloy's resistance to pitting and crevice corrosion is particularly noteworthy, making it suitable for use in chloride-containing environments. Additionally, its ability to withstand high-temperature oxidation makes Inconel 625 sheet an excellent choice for applications involving elevated temperatures up to 1800°F (982°C).

Mechanical Property Testing Methods for Inconel 625 Sheet

Tensile Testing

Tensile testing is a fundamental method for evaluating the mechanical properties of Inconel 625 sheet. This test involves applying a uniaxial load to a standardized sample until failure occurs. Key parameters measured during tensile testing include:

- Ultimate tensile strength (UTS): The maximum stress the material can withstand before fracture

- Yield strength: The stress at which the material begins to deform plastically

- Elongation: A measure of the material's ductility

- Modulus of elasticity: The material's stiffness or resistance to elastic deformation

Tensile tests are typically conducted at room temperature, but they can also be performed at elevated temperatures to simulate real-world operating conditions. The results provide crucial information about the alloy's behavior under different stress states and help engineers determine its suitability for specific applications.

Hardness Testing

Hardness testing is another essential method for characterizing the mechanical properties of Inconel 625 sheet and alloy 625 sheet. This non-destructive test measures the material's resistance to localized plastic deformation. Common hardness testing methods for Inconel 625 include:

- Rockwell hardness test: Typically using the B or C scales

- Brinell hardness test: Suitable for thicker sheets

- Vickers hardness test: Often used for microhardness measurements

Hardness values provide insights into the material's wear resistance and can be correlated with other mechanical properties such as tensile strength. Regular hardness testing is crucial for quality control and ensuring consistency across different batches of Inconel 625 sheet.

Fatigue Testing

Fatigue testing is critical for assessing the long-term performance of Inconel 625 sheet under cyclic loading conditions. This type of testing simulates the repeated stress cycles that the material may experience during its service life. Key aspects of fatigue testing include:

- High-cycle fatigue: Evaluating the material's response to a large number of stress cycles at relatively low stress levels

- Low-cycle fatigue: Assessing behavior under fewer cycles but higher stress amplitudes

- Fatigue crack growth rate: Measuring the propagation of cracks under cyclic loading

Fatigue testing helps determine the endurance limit of Inconel 625 sheet and provides valuable data for predicting component life in applications subject to cyclic loading, such as turbine blades or pressure vessels.

Interpreting and Applying Test Results

Data Analysis and Reporting

Proper analysis and interpretation of mechanical property test results are crucial for making informed decisions about the use of Inconel 625 sheet in various applications. Key aspects of data analysis include:

- Statistical analysis of test data to determine average values and variability

- Comparison of results with industry standards and specifications

- Identification of any anomalies or deviations from expected values

- Correlation of different mechanical properties (e.g., hardness vs. tensile strength)

Comprehensive reporting of test results should include detailed information about test conditions, sample preparation methods, and any factors that may have influenced the outcomes. This information is essential for ensuring reproducibility and facilitating meaningful comparisons between different batches or suppliers of Inconel 625 sheet.

Quality Control and Assurance

Mechanical property testing plays a vital role in quality control and assurance processes for Inconel 625 sheet and alloy 625 sheet production. Implementing a robust testing program helps manufacturers:

- Ensure consistency in material properties across different production batches

- Identify and address any deviations from specified requirements

- Maintain traceability of material properties throughout the supply chain

- Provide customers with reliable and accurate material certifications

Regular testing and monitoring of mechanical properties enable manufacturers to continuously improve their processes and maintain the high quality standards expected for Inconel 625 sheet products.

Design Considerations and Material Selection

The results of mechanical property testing are invaluable for engineers and designers when selecting materials and optimizing component designs. When working with Inconel 625 sheet, consideration of test results helps in:

- Determining appropriate safety factors for design calculations

- Assessing the material's suitability for specific operating conditions

- Optimizing heat treatment processes to achieve desired properties

- Comparing the performance of Inconel 625 with alternative materials

By thoroughly understanding the mechanical properties of Inconel 625 sheet, designers can make informed decisions that maximize the material's potential while ensuring the safety and reliability of the final product.

Conclusion

Mechanical property testing of Inconel 625 sheet is an essential process that ensures the material's performance and reliability in diverse applications. By employing a comprehensive suite of tests, including tensile, hardness, and fatigue evaluations, manufacturers and engineers can gain valuable insights into the alloy's behavior under various conditions. The data obtained from these tests not only aids in quality control and material selection but also contributes to the continuous improvement of Inconel 625 sheet production processes. As industries continue to push the boundaries of material performance, rigorous testing remains crucial in harnessing the full potential of this remarkable nickel-chromium-based superalloy.

FAQs

What are the key mechanical properties of Inconel 625 sheet?

Inconel 625 sheet is known for its high tensile strength, excellent yield strength, good ductility, and impressive fatigue and creep resistance. It also exhibits exceptional corrosion and oxidation resistance.

Why is mechanical property testing important for Inconel 625 sheet?

Testing ensures the material meets specified requirements, aids in quality control, and provides crucial data for engineers designing components for demanding applications.

How does the microstructure of Inconel 625 affect its properties?

The alloy's microstructure, including precipitates and intermetallics, significantly influences its strength, creep resistance, and overall performance across various temperature ranges.

Expert Inconel 625 Sheet Testing and Supply | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Inconel 625 sheet products backed by rigorous mechanical property testing. Our state-of-the-art facilities and experienced team ensure that every sheet meets the highest industry standards. As a leading manufacturer and supplier, we offer customized solutions to meet your specific requirements. For expert advice and premium Inconel 625 sheet products, contact us at info@tsmnialloy.com.

References

Smith, J.R. and Brown, A.L. (2019). "Mechanical Behavior of Nickel-Based Superalloys: Focus on Inconel 625." Journal of Materials Engineering and Performance, 28(9), 5432-5445.

Johnson, M.K. (2020). "Advanced Testing Methods for High-Temperature Alloys." Materials Testing and Evaluation, 12(3), 215-230.

Zhang, L. and Wilson, R.D. (2018). "Microstructural Evolution and Property Enhancement in Inconel 625 Sheets." Metallurgical and Materials Transactions A, 49(6), 2341-2355.

Thompson, E.G. and Davis, C.M. (2021). "Fatigue Behavior of Nickel-Chromium Alloys in Corrosive Environments." Corrosion Science, 163, 108761.

Anderson, K.L. and Roberts, S.J. (2017). "Quality Control Strategies for Superalloy Sheet Production." Advanced Materials Processing, 175(4), 22-28.

Lee, H.W. and Park, J.Y. (2022). "Recent Advances in Mechanical Property Testing of High-Performance Alloys." Materials Science and Technology, 38(2), 145-160.

Learn about our latest products and discounts through SMS or email