Understanding Inconel 718 Properties and Machining Challenges

Composition and Characteristics of Inconel 718

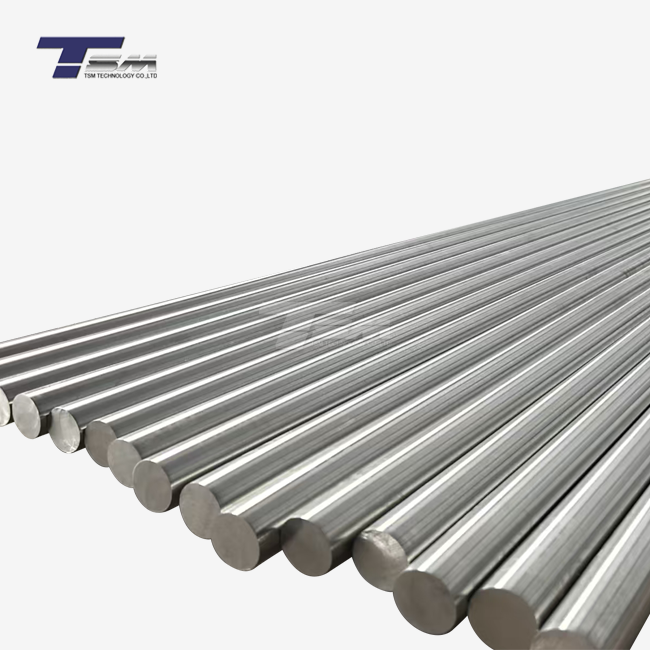

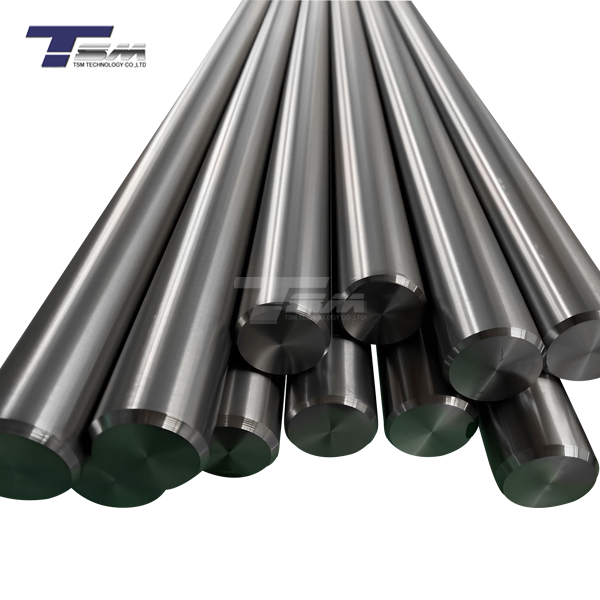

Inconel 718 is a precipitation-hardening nickel-chromium alloy renowned for its exceptional strength and corrosion resistance at elevated temperatures. Its unique composition, which includes nickel, chromium, iron, and small amounts of niobium, molybdenum, and titanium, contributes to its remarkable properties. These characteristics make Inconel 718 bar stock an ideal choice for applications in aerospace, oil and gas, and nuclear industries.

The alloy's high strength-to-weight ratio, excellent fatigue resistance, and ability to maintain its mechanical properties at temperatures up to 1300°F (704°C) make it a preferred material for critical components. However, these same properties also present significant challenges when machining Inconel 718 round bars.

Work Hardening and Heat Generation

One of the primary challenges in machining Inconel 718 bars is the material's tendency to work harden rapidly during cutting operations. As the cutting tool engages with the workpiece, the alloy's structure changes, becoming increasingly harder and more resistant to further machining. This phenomenon can lead to accelerated tool wear, reduced cutting speeds, and compromised surface finish quality.

Additionally, the low thermal conductivity of Inconel 718 results in heat concentration at the cutting zone. This heat buildup can cause thermal softening of the cutting tool edge, leading to premature tool failure and poor surface quality. Managing heat generation and dissipation is crucial for the successful machining of Inconel 718 round bars.

Chip Formation and Built-up Edge

The high ductility and toughness of Inconel 718 often result in the formation of long, continuous chips during machining. These chips can wrap around the workpiece or tooling, potentially causing surface damage or tool breakage. Furthermore, the material's adhesive nature can lead to built-up edge (BUE) formation on cutting tools, affecting dimensional accuracy and surface finish.

Understanding these inherent challenges is essential for developing effective strategies to machine Inconel 718 bar stock efficiently and with high precision.

Selecting the Right Cutting Tools and Parameters

Cutting Tool Materials and Coatings

Choosing the appropriate cutting tool material is crucial when machining Inconel 718 round bars. Carbide tools, particularly those with cobalt-enriched substrates, offer a good balance of hardness and toughness required for this demanding application. For high-speed machining operations, ceramic tools, such as silicon nitride (Si3N4) or whisker-reinforced alumina, can provide excellent wear resistance and thermal stability.

Tool coatings play a vital role in enhancing tool life and performance when machining Inconel 718 bar stock. Multi-layer coatings combining TiAlN (Titanium Aluminum Nitride) and AlCrN (Aluminum Chromium Nitride) have shown promising results, offering improved wear resistance and thermal barrier properties. PVD (Physical Vapor Deposition) coatings are generally preferred due to their ability to maintain sharp cutting edges.

Cutting Speed and Feed Rate Optimization

When machining Inconel 718 bars, it's crucial to strike a balance between productivity and tool life. Generally, lower cutting speeds and higher feed rates are recommended compared to those used for conventional steels. Starting with conservative cutting parameters and gradually optimizing based on observed performance is a prudent approach.

For carbide tools, typical cutting speeds range from 30 to 50 m/min (100 to 165 ft/min) for turning operations, while feed rates can vary between 0.1 to 0.3 mm/rev (0.004 to 0.012 in/rev) depending on the specific operation and desired surface finish. High-speed machining with ceramic tools may allow for cutting speeds up to 200 m/min (656 ft/min), but requires careful consideration of tool wear and workpiece integrity.

Tool Geometry and Chip Control

Optimizing tool geometry is essential for effective chip control and heat management when machining Inconel 718 round bars. Positive rake angles between 5° and 15° help reduce cutting forces and heat generation. Sharp cutting edges are generally preferred to minimize work hardening, but a small edge preparation (honing) can enhance edge strength without significantly increasing cutting forces.

Chip breakers designed specifically for nickel-based alloys can help manage chip formation and evacuation. These features should promote chip curling and breaking without excessive deformation of the workpiece material. Proper chip control not only improves surface finish but also enhances tool life and machining stability.

Advanced Machining Strategies for Inconel 718 Round Bars

High-Pressure Coolant Applications

Implementing high-pressure coolant systems can significantly improve machining performance when working with Inconel 718 bar stock. Coolant pressures ranging from 70 to 100 bar (1000 to 1450 psi) directed precisely at the cutting edge help in several ways:

- Enhanced chip breaking and evacuation

- Improved heat dissipation from the cutting zone

- Reduced friction between the tool and workpiece

- Increased tool life and surface finish quality

When using high-pressure coolant, it's important to ensure proper nozzle positioning and consider the impact on chip evacuation to prevent chip re-cutting and surface damage.

Cryogenic Machining Techniques

Cryogenic machining, using liquid nitrogen or carbon dioxide as a coolant, has shown promising results in machining difficult-to-cut materials like Inconel 718. This technique involves delivering cryogenic fluid directly to the cutting zone, dramatically reducing temperatures and potentially allowing for higher cutting speeds.

Benefits of cryogenic machining for Inconel 718 round bars include:

- Significant reduction in tool wear rates

- Improved surface integrity of machined components

- Potential for increased material removal rates

- Environmentally friendly alternative to traditional coolants

While cryogenic machining offers substantial advantages, it requires specialized equipment and careful process optimization to fully leverage its benefits.

Vibration-Assisted Machining (VAM)

Vibration-assisted machining is an innovative technique that can enhance the machinability of Inconel 718 bars. By introducing controlled, high-frequency vibrations to the cutting tool or workpiece, VAM can:

- Reduce cutting forces and tool wear

- Improve chip breaking and evacuation

- Enhance surface finish quality

- Allow for potentially higher material removal rates

VAM can be particularly effective in operations such as drilling and tapping of Inconel 718 round bars, where traditional methods often struggle with chip evacuation and tool life. However, implementing VAM requires specialized equipment and careful process development to ensure optimal results.

Conclusion

Machining Inconel 718 round bars demands a comprehensive understanding of the material's properties and the challenges they present. By selecting appropriate cutting tools, optimizing machining parameters, and implementing advanced strategies like high-pressure coolant, cryogenic machining, or vibration-assisted machining, engineers and machinists can significantly improve their productivity and part quality. As technology continues to evolve, staying informed about the latest developments in cutting tool materials, coatings, and machining techniques is crucial for maintaining a competitive edge in the precision engineering of Inconel 718 components.

Contact Us

For expert guidance on sourcing high-quality Inconel 718 bar stock and other superior nickel alloys for your precision engineering projects, contact TSM TECHNOLOGY. Our team of specialists is ready to assist you in selecting the ideal materials and providing insights to optimize your machining processes. Reach out to us at info@tsmnialloy.com to discuss your specific requirements and discover how our premium alloy products can enhance your manufacturing capabilities.