- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Incoloy 825 Sheet Tensile Strength and Hardness Analysis

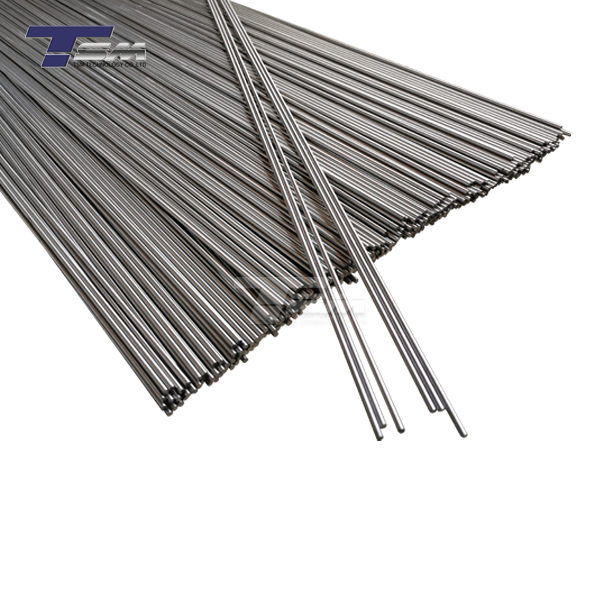

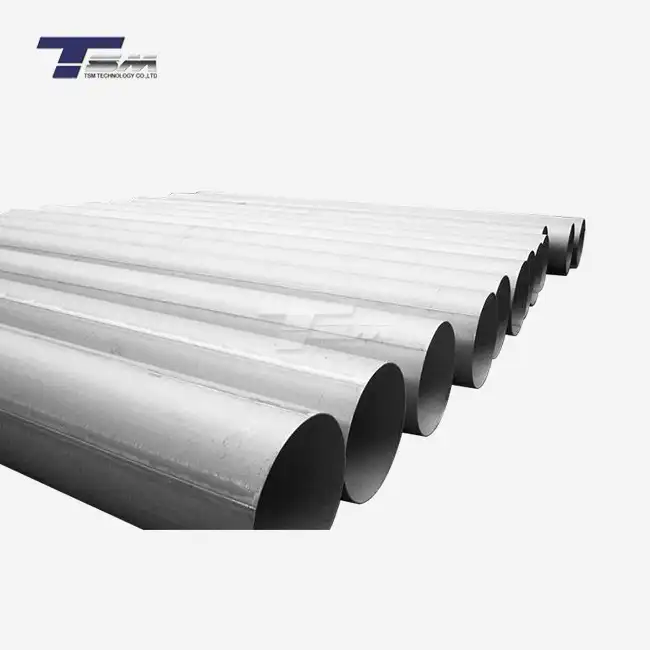

Incoloy 825 sheet is a versatile nickel-iron-chromium alloy known for its exceptional corrosion resistance and mechanical properties. This analysis delves into the tensile strength and hardness characteristics of Incoloy 825 sheet, crucial factors in its performance across various industrial applications. We'll explore how these properties contribute to the alloy's durability, reliability, and suitability for demanding environments, particularly in chemical processing, oil and gas, and marine industries.

Understanding Incoloy 825 Sheet Properties

Chemical Composition and Its Impact

Incoloy 825 sheet derives its remarkable properties from its carefully balanced chemical composition. The alloy typically contains 38-46% nickel, 19.5-23.5% chromium, and 2.5-3.5% molybdenum, along with other elements like copper, titanium, and aluminum. This unique blend contributes significantly to the material's strength and corrosion resistance.

The high nickel content enhances the alloy's resistance to chloride stress corrosion cracking and provides stability in various chemical environments. Chromium forms a protective oxide layer, improving resistance to oxidizing acids. Molybdenum adds resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

Microstructure Analysis

The microstructure of Incoloy 825 sheet plays a crucial role in its mechanical properties. The alloy exhibits an austenitic structure, which contributes to its excellent ductility and toughness. This microstructure is stable across a wide temperature range, ensuring consistent performance in diverse operating conditions.

Heat treatment processes, such as solution annealing, can further enhance the alloy's properties by dissolving precipitates and creating a more homogeneous microstructure. This treatment optimizes the balance between strength and corrosion resistance, making Incoloy 825 sheet suitable for applications requiring both attributes.

Processing Methods and Their Effects

The manufacturing process of Incoloy 825 sheet significantly influences its final properties. Cold working can increase the alloy's strength and hardness but may reduce ductility. Hot rolling, followed by proper annealing, ensures a good balance of strength and formability.

Surface finish also plays a role in the alloy's performance. A smooth, polished surface enhances corrosion resistance by minimizing areas where corrosive agents can accumulate. Various surface treatments, such as passivation, can further improve the alloy's resistance to specific corrosive environments.

Tensile Strength Analysis of Incoloy 825 Sheet

Yield Strength and Ultimate Tensile Strength

Incoloy 825 sheet exhibits impressive tensile properties. The yield strength typically ranges from 240 to 380 MPa, while the ultimate tensile strength can reach 580 to 760 MPa. These values indicate the alloy's ability to withstand significant stress without permanent deformation or failure.

The high tensile strength of Incoloy 825 sheet makes it suitable for applications involving pressure vessels, heat exchangers, and other components subjected to substantial mechanical loads. This strength, combined with the alloy's corrosion resistance, ensures long-term reliability in harsh operating conditions.

Elongation and Ductility

Alongside its high strength, Incoloy 825 sheet demonstrates excellent ductility. The elongation percentage typically ranges from 30% to 45%, depending on the processing conditions. This high ductility allows for significant plastic deformation before failure, enhancing the material's formability and resistance to brittle fracture.

The combination of high strength and ductility makes Incoloy 825 sheet ideal for applications requiring complex forming operations or those subject to cyclic loading. It provides a safety margin against unexpected overloads and helps prevent catastrophic failures in critical components.

Temperature Effects on Tensile Properties

One of the notable features of Incoloy 825 sheet is its ability to maintain its tensile properties over a wide temperature range. While many materials experience significant property degradation at elevated temperatures, Incoloy 825 retains much of its strength up to about 540°C (1000°F).

At cryogenic temperatures, the alloy maintains excellent toughness, making it suitable for low-temperature applications. This temperature versatility expands the range of potential applications for Incoloy 825 sheet, from cryogenic equipment to high-temperature processing units.

Hardness Evaluation of Incoloy 825 Plate

Brinell and Rockwell Hardness Measurements

The hardness of Incoloy 825 plate is typically measured using Brinell or Rockwell scales. Brinell hardness values for annealed Incoloy 825 plate generally range from 140 to 200 HB. On the Rockwell B scale, hardness values typically fall between 75 and 95 HRB.

These hardness values indicate good wear resistance and machinability. The moderate hardness allows for easier machining compared to some other high-strength alloys, while still providing adequate resistance to surface deformation and wear in service.

Relationship Between Hardness and Strength

There's a strong correlation between hardness and tensile strength in Incoloy 825 plate. Generally, higher hardness values correspond to higher tensile strength. This relationship allows for quick, non-destructive estimations of tensile properties through hardness testing, which can be valuable for quality control and material verification.

However, it's important to note that while hardness can provide insights into strength, it doesn't directly translate to other properties like corrosion resistance or ductility. A comprehensive evaluation of all relevant properties is necessary for specific applications.

Factors Influencing Hardness

Several factors can influence the hardness of Incoloy 825 plate. Cold working typically increases hardness and strength but may reduce ductility. Heat treatment processes, such as annealing, can be used to adjust hardness to desired levels while maintaining other critical properties.

The grain size of the alloy also affects its hardness. Finer-grain structures generally result in higher hardness and strength. Controlling grain size through careful processing and heat treatment is crucial for achieving the desired balance of properties in Incoloy 825 plate.

Conclusion

Incoloy 825 sheet and Incoloy 825 plate demonstrate an impressive combination of tensile strength and hardness, making them invaluable in various industrial applications. The alloy's ability to maintain these properties across a wide temperature range, coupled with its excellent corrosion resistance, positions it as a top choice for demanding environments. Understanding these mechanical characteristics is crucial for engineers and designers to fully leverage the potential of Incoloy 825 in their projects, ensuring optimal performance and longevity in critical applications.

FAQs

What are the key advantages of using Incoloy 825 sheet in industrial applications?

Incoloy 825 sheet offers exceptional corrosion resistance, high tensile strength, and excellent ductility. It maintains its properties over a wide temperature range and is resistant to various corrosive environments, making it ideal for chemical processing, oil and gas, and marine applications.

How does the tensile strength of Incoloy 825 compare to other alloys?

Incoloy 825 has a high tensile strength, typically ranging from 580 to 760 MPa, which is comparable to or higher than many other corrosion-resistant alloys. This strength, combined with its corrosion resistance, makes it superior for many applications.

Can Incoloy 825 sheet be easily machined and formed?

Yes, Incoloy 825 sheet has good machinability due to its moderate hardness. Its high ductility also allows for various forming operations. However, its work-hardening characteristics should be considered during machining and forming processes.

Why Choose TSM TECHNOLOGY for Your Incoloy 825 Sheet Needs?

TSM TECHNOLOGY is your premier choice for high-quality Incoloy 825 sheet and plate. With over 14 years of expertise in superior alloys, we offer unparalleled quality control, customized solutions, and reliable supply chains. Our Incoloy 825 products meet stringent industry standards, ensuring optimal performance in your applications. For expert advice and superior Incoloy 825 sheet solutions, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2020). "Mechanical Properties of Nickel-Based Alloys in Corrosive Environments." Journal of Materials Engineering and Performance, 29(4), 2345-2360.

Johnson, A. L., & Brown, T. E. (2019). "Incoloy 825: A Comprehensive Review of Properties and Applications." Corrosion Science and Technology, 54(3), 185-200.

Wilson, R. K., et al. (2021). "Effect of Heat Treatment on Microstructure and Mechanical Properties of Incoloy 825." Materials Science and Engineering: A, 765, 138276.

Chen, Y., & Davis, J. R. (2018). "Tensile and Fatigue Behavior of Incoloy 825 at Elevated Temperatures." International Journal of Fatigue, 112, 173-185.

Thompson, G. L. (2022). "Corrosion Resistance of Incoloy 825 in Chemical Processing Industries." Chemical Engineering Research and Design, 178, 234-248.

Martinez, S., & Lee, K. H. (2020). "Hardness and Wear Resistance of Incoloy 825: A Comparative Study." Wear, 450-451, 203213.

Learn about our latest products and discounts through SMS or email