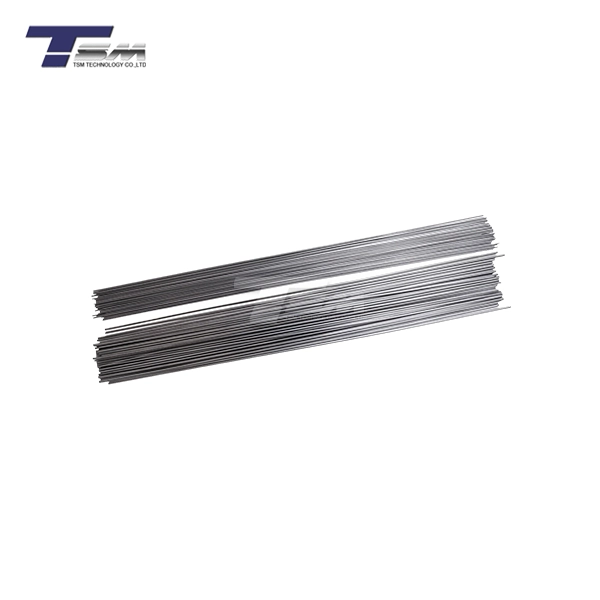

The Forging Process: Shaping Monel 400 into Bars

Raw Material Preparation

The journey of Monel 400 bar production begins with carefully selected raw materials. High-purity nickel and copper are combined in precise proportions to create the Monel 400 alloy. This mixture is then melted in specialized furnaces under controlled atmospheric conditions to ensure optimal composition and purity. The molten alloy undergoes a rigorous refining process to remove impurities and achieve the desired chemical properties that make Monel 400 renowned for its corrosion resistance and strength.

Hot Forging Techniques

Once the Monel 400 round bars alloy is prepared, it enters the hot forging stage. This process involves heating the material to temperatures typically ranging between 1800°F to 2100°F (982°C to 1149°C). At these elevated temperatures, the alloy becomes more malleable, allowing for easier shaping into bars. Hydraulic presses or forging hammers apply controlled pressure to the heated material, gradually forming it into the desired bar shape. The hot forging process not only shapes the Monel 400 but also helps to refine its grain structure, enhancing its mechanical properties.

Cold Working for Precision

After hot forging, some Monel 400 bars undergo cold working processes to further refine their dimensions and improve mechanical properties. Cold drawing or cold rolling techniques are employed to achieve tighter tolerances and a smoother surface finish. This step is particularly crucial for applications requiring high-precision Monel round bars. The cold working process can increase the strength and hardness of the material while maintaining its excellent corrosion resistance, making Monel 400 bars suitable for a wide range of demanding applications.

Heat Treatment: Enhancing Monel 400 Bar Properties

Annealing for Workability

Heat treatment plays a vital role in optimizing the properties of Monel 400 bars. Annealing is a critical heat treatment process that involves heating the bars to temperatures between 1600°F to 1800°F (871°C to 982°C) and then slowly cooling them. This process relieves internal stresses accumulated during forging and cold working, improving the material's ductility and workability. Annealed Monel 400 bars exhibit enhanced formability, making them ideal for applications requiring further shaping or machining.

Stress Relieving

For Monel 400 bars subjected to extensive cold working or machining, stress relieving treatments are often necessary. This process involves heating the bars to moderate temperatures, typically between 900°F to 1200°F (482°C to 649°C), and holding them at this temperature for a specified duration before cooling. Stress relieving helps to eliminate residual stresses that could potentially lead to dimensional instability or premature failure in service. This treatment ensures that Monel bars maintain their dimensional accuracy and structural integrity under various operating conditions.

Age Hardening for Strength

In applications requiring higher strength, Monel 400 bars can undergo age hardening treatments. This process involves heating the material to temperatures around 1100°F to 1300°F (593°C to 704°C) for several hours, followed by air cooling. Age hardening promotes the formation of fine precipitates within the alloy's microstructure, significantly increasing its strength and hardness. This treatment is particularly beneficial for Monel 400 round bars used in high-stress environments, providing an optimal balance of strength and corrosion resistance.

Finishing Touches: Precision and Quality Assurance

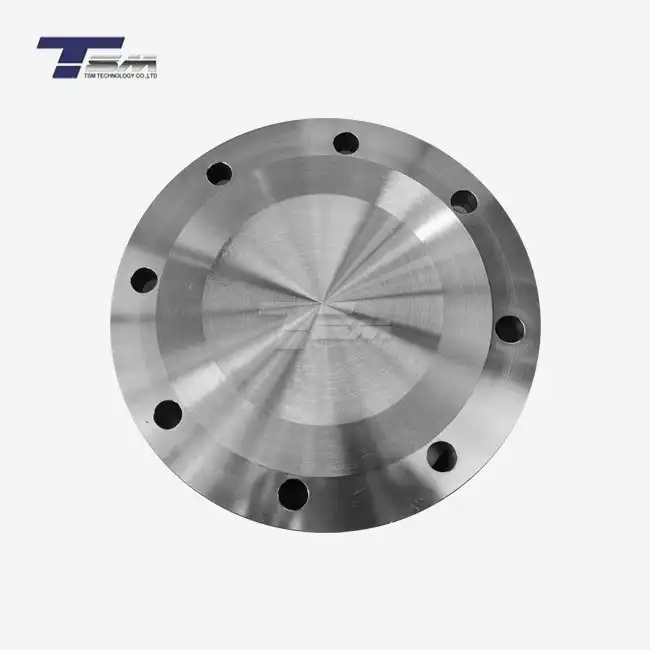

Surface Treatment and Polishing

The final stages of Monel 400 bar processing focus on achieving the desired surface quality and appearance. Various surface treatment methods are employed, depending on the specific requirements of the end application. Grinding and polishing techniques are used to create a smooth, uniform surface finish on Monel bars. For applications requiring enhanced corrosion resistance or aesthetic appeal, electropolishing may be applied. This electrochemical process removes a thin layer of material from the surface, resulting in a bright, smooth finish that further improves the bar's corrosion resistance and cleanability.

Dimensional Inspection and Tolerance Control

Precision is paramount in the production of high-quality Monel 400 bars. Rigorous dimensional inspections are conducted throughout the manufacturing process to ensure compliance with specified tolerances. Advanced measurement tools, such as laser micrometers and coordinate measuring machines, are utilized to verify the dimensional accuracy of Monel round bars. This meticulous attention to detail guarantees that the finished bars meet or exceed industry standards and customer specifications, making them suitable for critical applications in aerospace, marine, and chemical processing industries.

Non-Destructive Testing and Quality Certification

To ensure the highest level of quality and reliability, Monel 400 bars undergo comprehensive non-destructive testing (NDT) procedures. These may include ultrasonic testing to detect internal flaws, eddy current testing for surface defect detection, and magnetic particle inspection for ferromagnetic variants. Each batch of Monel bars is subject to chemical composition analysis and mechanical property testing to verify compliance with material specifications. The results of these tests are documented in quality certificates, providing customers with assurance of the material's integrity and performance capabilities.

Conclusion

The journey from forging to finishing in Monel 400 bar processing exemplifies the intricate balance of metallurgical science and precision engineering. Through carefully controlled forging processes, strategic heat treatments, and meticulous finishing techniques, raw Monel 400 is transformed into high-performance bars capable of withstanding the most demanding environments. This comprehensive approach to manufacturing ensures that each Monel 400 bar, whether standard or custom-sized, meets the exacting standards required by industries reliant on superior corrosion resistance and mechanical strength. The result is a product that not only meets but often exceeds the expectations of engineers and designers across a spectrum of critical applications.

Contact Us

For more information on our premium Monel 400 bars and custom processing capabilities, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the ideal Monel 400 product for your specific needs, ensuring optimal performance and longevity in your applications.

_1739071678907.webp)