Understanding Inconel 718 and Its Machining Challenges

Composition and Properties of Inconel 718

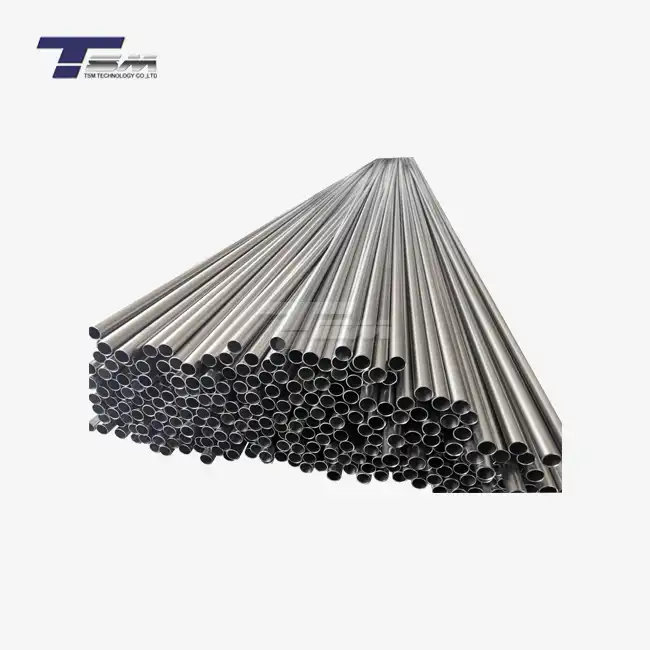

Inconel 718 is a high-strength, corrosion-resistant nickel-chromium-based superalloy. Its unique composition, which includes elements like niobium, molybdenum, and titanium, contributes to its exceptional properties. This alloy maintains its strength at temperatures up to 1300°F (704°C), making it ideal for high-temperature applications. The material's ability to resist oxidation and maintain dimensional stability under extreme conditions has made Inconel 718 bar a preferred choice in demanding environments.

Challenges in Machining Inconel 718

Machining Inconel 718 round bar presents several challenges due to its inherent properties. The alloy's work-hardening tendency can lead to rapid tool wear and poor surface finish if not properly managed. Its low thermal conductivity causes heat concentration at the cutting zone, potentially resulting in built-up edge formation and accelerated tool deterioration. Additionally, the high strength of Inconel 718 bar stock necessitates higher cutting forces, which can lead to vibration and chatter during machining operations.

Importance of Surface Finish in Inconel 718 Components

A superior surface finish on Inconel 718 components is crucial for several reasons. It enhances fatigue resistance, improves corrosion resistance, and ensures better dimensional accuracy. In aerospace applications, where Inconel 718 bars are frequently used for turbine disks and shafts, a high-quality surface finish is essential for maintaining the integrity of critical components under extreme operating conditions. Moreover, a smooth surface reduces friction and wear in moving parts, contributing to improved efficiency and longevity of the machinery.

Advanced Machining Techniques for Improved Surface Finish

High-Speed Machining (HSM) for Inconel 718

High-speed machining has emerged as an effective technique for improving the surface finish of Inconel 718 round bars. By utilizing higher cutting speeds and feed rates, HSM reduces the contact time between the tool and the workpiece, minimizing heat generation and work hardening. This approach results in a smoother surface finish and can potentially increase material removal rates. When implementing HSM for Inconel 718 bar stock, it's crucial to optimize cutting parameters such as spindle speed, feed rate, and depth of cut to achieve the best results.

Cryogenic Machining

Cryogenic machining involves the use of super-cooled gases or liquids, typically liquid nitrogen, as a coolant during the cutting process. This technique has shown promising results in improving the surface finish of Inconel 718 bars. The cryogenic coolant effectively removes heat from the cutting zone, reducing thermal softening and tool wear. As a result, the machined surface exhibits improved quality with reduced roughness. Additionally, cryogenic machining can potentially increase tool life and allow for higher cutting speeds, further enhancing productivity in Inconel 718 bar machining operations.

Ultrasonic-Assisted Machining

Ultrasonic-assisted machining is an innovative approach that combines conventional cutting with high-frequency vibrations. When applied to Inconel 718 round bar machining, this technique can significantly improve surface finish quality. The ultrasonic vibrations reduce cutting forces and chip thickness, resulting in a more uniform and smoother surface. This method is particularly effective in reducing built-up edge formation and minimizing work hardening effects, both of which are common challenges when machining Inconel 718 bar stock.

Optimizing Cutting Tools and Parameters

Selection of Appropriate Cutting Tools

Choosing the right cutting tools is paramount for achieving an excellent surface finish on Inconel 718 bars. Carbide tools with specialized coatings, such as TiAlN or AlCrN, have shown superior performance in machining this superalloy. These coatings enhance tool hardness and thermal resistance, crucial for maintaining edge sharpness during the cutting process. Ceramic tools, particularly those reinforced with whiskers, offer another viable option for high-speed machining of Inconel 718 bar stock. Their high hardness and wear resistance make them suitable for achieving fine surface finishes at elevated cutting speeds.

Optimizing Cutting Speed and Feed Rate

Determining the optimal cutting speed and feed rate is essential for improving the surface finish of Inconel 718 round bars. Generally, higher cutting speeds combined with moderate feed rates yield better surface quality. However, these parameters must be carefully balanced to prevent excessive heat generation and tool wear. For instance, when turning Inconel 718 bars, cutting speeds between 30-50 m/min with feed rates of 0.1-0.2 mm/rev have been found effective for achieving smooth surfaces. It's important to note that these values may vary depending on the specific machining operation and tool geometry.

Implementing Advanced Coolant Strategies

Effective coolant application plays a crucial role in enhancing surface finish quality when machining Inconel 718 bar stock. High-pressure coolant systems that deliver coolant directly to the cutting zone have shown significant improvements in surface finish and tool life. These systems help in chip evacuation and reduce heat buildup at the tool-workpiece interface. Minimum quantity lubrication (MQL) is another innovative approach that can be employed. MQL uses a fine mist of oil and compressed air, providing adequate lubrication while minimizing thermal shock, which is particularly beneficial when machining Inconel 718 bars.

Conclusion

Improving the surface finish of Inconel 718 round bars through machining is a multifaceted process that requires a comprehensive approach. By leveraging advanced machining techniques, selecting appropriate cutting tools, and optimizing machining parameters, manufacturers can significantly enhance the quality of machined Inconel 718 surfaces. These improvements not only result in superior component performance but also contribute to increased productivity and reduced manufacturing costs. As technology continues to evolve, staying abreast of the latest developments in machining processes and tools will be crucial for anyone working with Inconel 718 bar stock in high-performance applications.

Contact Us

For more information on our high-quality Inconel 718 round bars and expert machining solutions, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists is ready to assist you in achieving the best results for your Inconel 718 machining projects.