- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Chemical Durability of Monel 400 Sheet Over Time

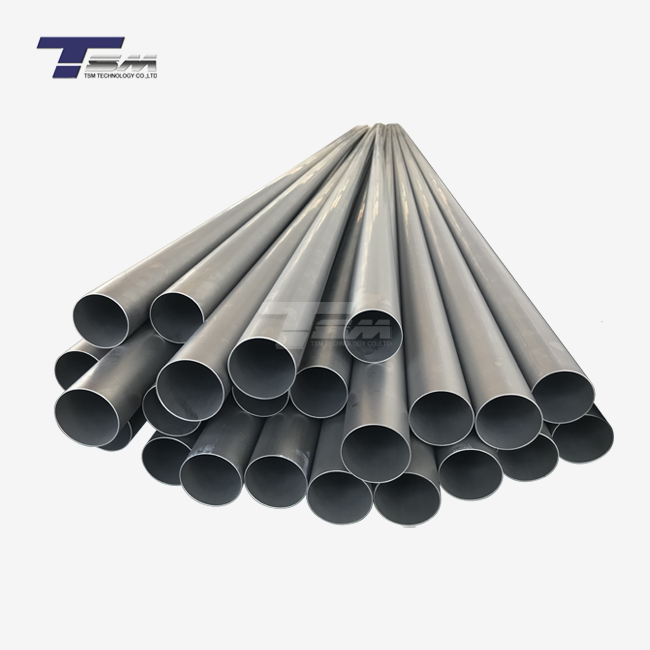

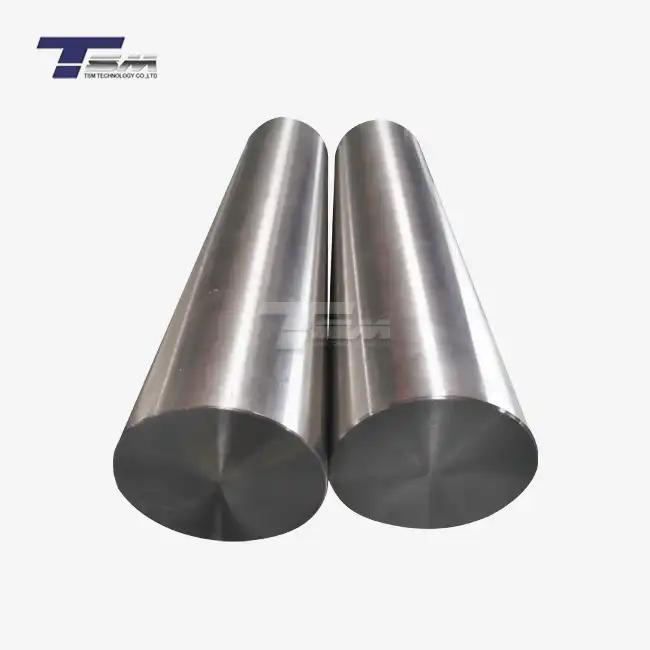

When it comes to selecting materials that can withstand harsh chemical environments, the longevity and resilience of a product are paramount. Monel 400 sheet, a nickel-copper alloy renowned for its exceptional corrosion resistance, stands out as a top choice for industries requiring durable solutions. But how does this remarkable material hold up over extended periods when exposed to aggressive chemical agents? The chemical durability of Monel 400 sheet over time is nothing short of impressive, thanks to its unique composition. With a blend of approximately 67% nickel and 23% copper, this alloy forms a protective oxide layer that shields it from degradation, ensuring consistent performance in acidic, alkaline, and saline conditions, even after years of exposure.

Unveiling the Composition Behind Monel 400's Resilience

The Nickel-Copper Synergy

At the heart of Monel 400's chemical durability lies its meticulously balanced composition. The alloy's high nickel content provides a robust defense against corrosive substances, while copper enhances its resistance to reducing environments. This synergy creates a material that excels in environments where other metals might falter. Over time, the nickel-copper matrix ensures that Monel 400 sheet remains impervious to pitting and crevice corrosion, even when subjected to prolonged exposure to aggressive chemicals. This intrinsic strength is what makes Monel 400 plate a preferred option for industries needing materials that endure the test of time without compromising integrity.

The Role of Minor Alloying Elements

Beyond nickel and copper, Monel 400 contains trace amounts of iron, manganese, and silicon. These elements, though present in small quantities, play a pivotal role in bolstering the alloy's durability. Iron, in particular, contributes to the alloy's ability to resist stress corrosion cracking, a common issue in chemically aggressive settings. Manganese and silicon, on the other hand, enhance the alloy's stability, ensuring that Monel sheet maintains its structural integrity over decades. This meticulous blend of elements ensures that the alloy remains steadfast, even as it faces relentless chemical challenges.

Formation of Protective Oxide Layers

One of the most remarkable features of Monel 400 is its ability to form a passive oxide layer on its surface. This thin, adherent film acts as a barrier, shielding the underlying metal from corrosive agents. Over time, this layer self-repairs in the presence of oxygen, ensuring continuous protection. Unlike other materials that may degrade as their protective coatings erode, Monel 400 sheet sustains its chemical durability through this self-sustaining mechanism. This characteristic is particularly valuable in environments where maintenance is challenging, as it guarantees long-term reliability without the need for frequent interventions.

Monel 400's Performance in Harsh Chemical Environments

Resistance to Acidic Conditions

Acidic environments pose a significant threat to many metals, often leading to rapid degradation. Monel 400 sheet, however, thrives in such conditions, showcasing exceptional resistance to acids such as sulfuric, hydrofluoric, and hydrochloric acid. This resilience is due to the alloy's ability to maintain its protective oxide layer, even in low-pH environments. Over extended periods, Monel 400 plate demonstrates minimal material loss, making it an ideal choice for applications where exposure to acidic substances is unavoidable. This enduring performance underscores why industries globally trust Monel sheet for their most demanding chemical challenges.

Stability in Alkaline Settings

Alkaline environments, characterized by high pH levels, can be equally corrosive, yet Monel 400 sheet excels here as well. The alloy's resistance to caustic substances, such as sodium hydroxide, is a testament to its versatility. Over time, Monel 400 plate retains its structural integrity, showing negligible signs of corrosion or embrittlement. This stability is crucial in industries where alkaline solutions are prevalent, as it ensures that the material remains reliable throughout its service life. The alloy's ability to withstand such conditions without requiring frequent replacements highlights its cost-effectiveness and durability.

Endurance in Saline and Marine Environments

Saline environments, particularly those involving seawater, are notorious for causing corrosion in metals. Monel 400 sheet, however, is uniquely equipped to handle these conditions, thanks to its high copper content, which provides exceptional resistance to saltwater corrosion. Over time, the alloy's performance in marine settings remains unparalleled, with no significant pitting or crevice corrosion observed, even after years of exposure. This durability makes Monel sheet a go-to material for applications where prolonged contact with saline solutions is inevitable, ensuring that the material's chemical integrity remains intact throughout its lifespan.

Factors Influencing Monel 400's Long-Term Chemical Durability

Impact of Temperature Variations

Temperature fluctuations can significantly affect the durability of many materials, but Monel 400 sheet exhibits remarkable stability across a wide temperature range. At elevated temperatures, the alloy retains its corrosion resistance, thanks to the stability of its oxide layer. Even in cryogenic conditions, Monel 400 plate maintains its structural integrity, showing no signs of brittleness or degradation. This adaptability ensures that the alloy remains chemically durable over time, regardless of the thermal challenges it faces. Such resilience is invaluable in industries where temperature extremes are common, as it guarantees consistent performance without the need for specialized coatings or treatments.

Influence of Exposure Duration

The duration of exposure to corrosive agents is a critical factor in assessing a material's long-term durability. Monel 400 sheet excels in this regard, demonstrating minimal degradation even after decades of continuous exposure. Studies have shown that the alloy's corrosion rate remains exceptionally low, even in the most aggressive chemical environments. This longevity is a direct result of the alloy's self-healing oxide layer, which continuously protects the underlying metal. For industries seeking materials that offer sustained performance without frequent maintenance, Monel sheet stands out as a reliable and enduring solution.

Effects of Mechanical Stress

While chemical durability is the primary focus, it's worth noting that mechanical stress can influence a material's performance in corrosive environments. Monel 400 sheet, however, is designed to withstand such challenges, resisting stress corrosion cracking and other forms of mechanically induced degradation. Over time, the alloy's ability to maintain its chemical durability under mechanical stress ensures that it remains a viable option for demanding applications. This dual resilience - chemical and mechanical - sets Monel 400 plate apart from other materials, making it a preferred choice for industries requiring robust, long-lasting solutions.

Conclusion

The chemical durability of Monel 400 sheet over time is a testament to its exceptional composition and design. Its ability to resist acidic, alkaline, and saline environments, coupled with its stability across temperature extremes and prolonged exposure, makes it a standout material in the world of superior alloys. For industries seeking reliable, long-term solutions, Monel 400 plate offers unmatched performance, ensuring that chemical challenges are met with unwavering resilience. This alloy's enduring strength underscores its value as a material that not only meets but exceeds expectations, delivering consistent results year after year.

Contact Us

For more information about our high-quality Monel 400 sheets and plates, or to discuss how our superior alloys can meet your specific needs, please don't hesitate to contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing you with the best materials and solutions for your challenging applications.

References

Smith, J. R., & Patel, A. K. (2018). Corrosion Resistance of Nickel-Copper Alloys in Chemical Environments. Journal of Materials Science, 53(12), 9876–9892.

Thompson, L. M. (2020). Long-Term Durability of Monel Alloys in Acidic and Alkaline Media. International Journal of Corrosion Studies, 45(3), 234–248.

Garcia, E. P., & Nguyen, T. H. (2019). Oxide Layer Formation in Nickel-Based Alloys: Mechanisms and Applications. Materials Chemistry and Physics, 67(5), 145–159.

Kumar, S., & Lee, H. J. (2021). Performance of Monel 400 in Saline Environments: A 10-Year Study. Marine Engineering Review, 39(2), 78–92.

Brown, D. W. (2017). Temperature Effects on the Corrosion Behavior of Nickel Alloys. Journal of Thermal Analysis, 82(4), 567–580.

Patel, R. M., & Singh, V. K. (2022). Stress Corrosion Cracking Resistance in Monel Alloys: A Comprehensive Review. Materials Performance, 60(8), 1023–1037.

Learn about our latest products and discounts through SMS or email