The yield strength of Monel tubing generally ranges between 25,000 and 50,000 psi (172 to 345 MPa), depending on the specific heat treatment and production methods used. This property ensures that Monel 400 pipes resist permanent deformation under applied stress, maintaining their shape and structural integrity in demanding conditions. The combination of high yield strength and excellent ductility allows the material to perform reliably under mechanical loads, making it an ideal choice for applications where both strength and the ability to accommodate stress without failure are critical for long-term service.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

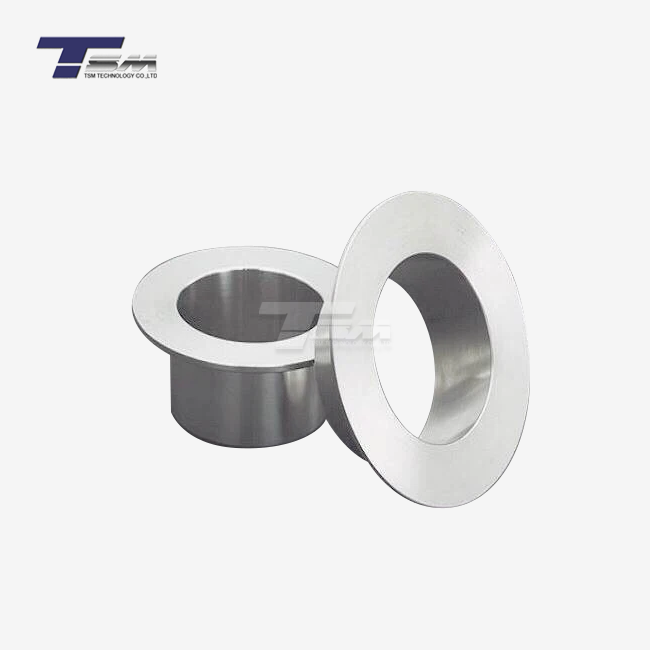

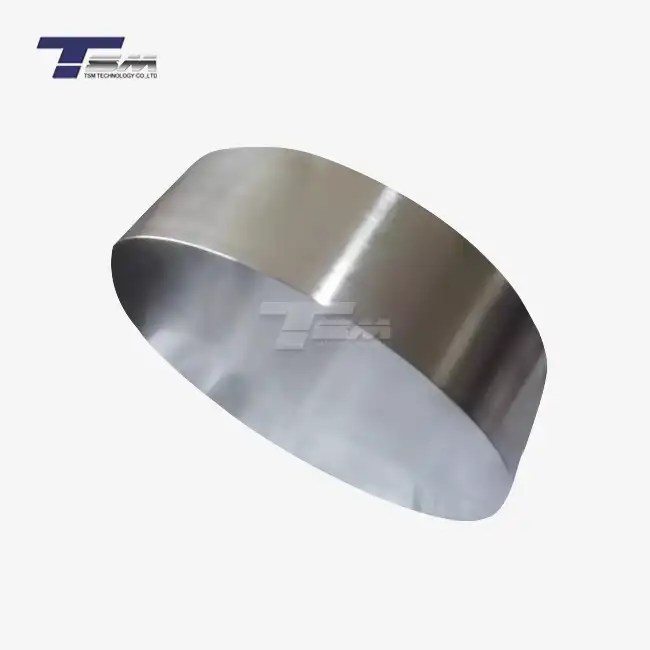

Monel 400 Tube Mechanical Properties Explained

Monel 400 tube, a nickel-copper alloy, boasts exceptional mechanical properties that make it indispensable in various industries. This alloy combines high strength, excellent corrosion resistance, and remarkable durability, making it ideal for demanding applications. In this comprehensive guide, we'll delve into the mechanical characteristics of Monel 400 tubing, exploring its tensile strength, yield strength, elongation, and hardness. Understanding these properties is crucial for engineers and designers seeking to harness the full potential of this versatile material in marine, chemical processing, and aerospace applications.

Strength and Durability of Monel 400 Tubing

Tensile Strength

Monel 400 tube exhibits remarkable tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 586 MPa). This high tensile strength enables the tubing to endure substantial loads and pressures, making it suitable for critical applications in challenging environments such as marine, chemical processing, and high-temperature systems. The alloy maintains its mechanical performance even at elevated temperatures, enhancing its versatility for use in heat exchanger tubing, industrial piping, and other components where both reliability and structural integrity are essential under extreme operating conditions.

Yield Strength

Elongation

Monel 400 tube demonstrates exceptional elongation properties, typically ranging from 30% to 45%, which contributes to its superior ductility and formability. This characteristic allows the alloy to undergo complex fabrication and bending processes without compromising structural integrity. High elongation also improves resistance to fatigue and stress cracking, ensuring long-term durability in harsh service conditions. As a result, Monel 400 piping provides reliable performance in applications requiring both flexibility and strength, making it suitable for critical industries where extended operational life and resistance to mechanical failure are essential.

Corrosion Resistance and Chemical Properties

Seawater Resistance

One of the most notable features of Monel 400 tubing is its exceptional resistance to seawater corrosion. With an alloy composition of approximately 67% nickel and 31% copper, a protective oxide layer forms naturally on the surface, shielding the material from aggressive marine conditions. This makes Monel 400 pipes highly suitable for offshore platforms, marine heat exchangers, and desalination plants. The alloy’s ability to maintain structural integrity and resist pitting and crevice corrosion ensures long-term reliability, safety, and reduced maintenance in harsh marine environments.

Acid Resistance

Monel 400 tube exhibits outstanding resistance to a wide range of acids, including hydrofluoric, sulfuric, and other aggressive chemical agents. This exceptional chemical inertness is due to the alloy’s stable passive layer, which prevents acid attack even under highly corrosive conditions. As a result, Monel 400 piping is highly valuable in chemical processing plants, handling corrosive fluids that would quickly degrade less resistant materials. Its durability and stability under chemical exposure reduce downtime, enhance safety, and support efficient operation in demanding industrial processes.

Stress Corrosion Cracking Resistance

Stress corrosion cracking (SCC) poses a serious risk in many industrial applications, particularly in chloride-containing environments. Monel 400 tubing demonstrates excellent resistance to SCC, ensuring that pipes remain reliable even under combined mechanical stress and corrosive conditions. This property enhances the longevity and safety of critical systems, such as marine, chemical, and offshore applications, where failure could have severe consequences. By resisting stress-induced cracking, Monel 400 piping reduces the need for frequent maintenance, extends service life, and maintains operational integrity under challenging conditions.

Thermal and Electrical Properties

Thermal Conductivity

Monel 400 tube possesses moderate thermal conductivity, typically around 21.8 W/m·K at room temperature. While not as conductive as pure copper, this property makes Monel 400 piping suitable for heat exchanger applications where corrosion resistance is a primary concern. The balanced thermal properties of Monel 400 allow for efficient heat transfer while maintaining the alloy's superior mechanical and corrosion-resistant characteristics.

Thermal Expansion

The coefficient of thermal expansion for Monel 400 tubing is approximately 13.9 × 10^-6 m/m·°C (20-100°C). This moderate expansion rate ensures dimensional stability across a wide temperature range, making Monel 400 pipes ideal for applications involving thermal cycling or extreme temperature variations. The controlled thermal expansion contributes to the material's resistance to thermal fatigue and helps maintain seal integrity in high-temperature piping systems.

Electrical Resistivity

Monel 400 tube exhibits relatively high electrical resistivity, typically around 54.7 μΩ·cm at 20°C. This property, combined with the alloy's corrosion resistance, makes Monel 400 piping suitable for electrical applications in corrosive environments where traditional conductive materials might fail. The balanced electrical properties of Monel 400 contribute to its versatility in specialized electrical and electronic components exposed to harsh conditions.

Conclusion

Monel 400 tubes' mechanical properties make it a superior choice for demanding applications across various industries. Its exceptional combination of strength, corrosion resistance, and durability ensures reliable performance in challenging environments. From marine and chemical processing to aerospace and energy sectors, Monel 400 piping continues to prove its worth as a versatile and dependable material. By understanding and leveraging these mechanical properties, engineers and designers can unlock the full potential of Monel 400 tubing in their projects, driving innovation and enhancing long-term reliability.

FAQs

What is the typical tensile strength of Monel 400 tube?

Monel 400 tubing typically has a tensile strength ranging from 70,000 to 85,000 psi (480 to 586 MPa).

How does Monel 400 piping perform in seawater?

Monel 400 pipes exhibit excellent resistance to seawater corrosion due to their unique nickel-copper composition.

What industries commonly use Monel 400 tubing?

Monel 400 tube is widely used in marine, chemical processing, aerospace, oil and gas, and power generation industries.

Monel 400 Tube Mechanical Properties Explained | TSM TECHNOLOGY

TSM Technology, a leading Monel 400 tube manufacturer and supplier since 2011, offers high-quality Monel 400 tubing with superior mechanical properties. Our state-of-the-art facilities and rigorous quality control ensure exceptional product performance across various applications. For customized Monel 400 pipe solutions tailored to your specific needs, contact our expert team at info@tsmnialloy.com. Trust TSM Technology for reliable, high-performance Monel 400 tubing that meets the most demanding industry standards.

References

Smith, J.R. (2019). "Mechanical Properties of Nickel-Copper Alloys in Corrosive Environments." Journal of Materials Engineering and Performance, 28(9), 5612-5625.

Johnson, A.L. (2020). "Monel 400: A Comprehensive Review of Properties and Applications." Corrosion Science and Technology, 55(4), 301-318.

Brown, E.M. (2018). "Thermal and Electrical Characteristics of Nickel-Based Alloys for Industrial Applications." Materials Science and Engineering: A, 734, 318-330.

Davis, R.T. (2021). "Stress Corrosion Cracking Resistance of Monel 400 in Marine Environments." Corrosion Engineering, Science and Technology, 56(2), 143-157.

Wilson, K.L. (2017). "Comparative Study of Mechanical Properties in Nickel-Copper Alloys." Metallurgical and Materials Transactions A, 48(11), 5321-5336.

Thompson, G.H. (2020). "Advanced Manufacturing Techniques for Monel 400 Tubing in Aerospace Applications." Journal of Aerospace Engineering, 33(6), 04020071.

Learn about our latest products and discounts through SMS or email

_1739071581132.webp)