- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Monel 401 Forgings in Oil & Gas Equipment

Monel 401 forgings are a revolutionary way for companies that make oil and gas equipment to deal with harsh conditions that corrode metals. These unique nickel-copper alloy parts work better than any other materials in places like pipelines, petrochemical plants, and offshore platforms where regular materials don't work. Monel 401 forgings are the best choice for critical uses like valves, pumps, heat exchangers, and pressure vessels because they are better at resisting seawater, hydrogen sulfide, and acidic conditions. Because of its special metal-working features, this alloy is very reliable over a long period of time and requires less upkeep, which saves money and time in harsh oil processing environments.

Understanding Monel 401 Forgings and Their Role in Oil & Gas Equipment

Understanding the unique qualities that make Monel 401 forgings essential is the first step to getting great results in oil and gas uses. The UNS N04401 nickel-copper alloy has a unique metallurgical structure that makes it very resistant to weathering. It is made up of about 63% nickel and 28–34% copper. Tensile strength is between 550 and 750 MPa, and elongation values are between 25 and 35%. This is because the composition is carefully adjusted.

Chemical Composition and Mechanical Properties

The unique performance profile of Monel 401 comes from the chemicals that make it up. These forgings stay strong in harsh situations because they have a melting point between 1300°C and 1350°C and a density of 8.8 g/cm³. When the metal is annealed, its minimum tensile strength is 760 MPa and its maximum yield strength is 345 MPa. Because it is strong and doesn't rust, it's perfect for parts that are exposed to hydrogen sulfide-containing sour gas conditions.

Applications in Oil & Gas Infrastructure

During oil and gas activities, these high-performance parts are used a lot. Forged Monel 401 parts are used in seawater service on offshore drilling platforms, and refineries use them in desulfurization units that are constantly exposed to corrosive compounds. Stress-corrosion cracking doesn't happen easily with this material, which makes it very useful for high-pressure pipe systems and wellhead equipment where failure could have terrible results.

Advantages Over Standard Materials

With better performance in chloride-rich conditions than regular stainless steels, Monel 401 forgings are great. When used in salt water, the metal is much more resistant to pitting and crevice corrosion than 316L stainless steel. The material also keeps its mechanical qualities at high temperatures, which means it can be used in places where hot hydrocarbons and steam systems are common, like oil and gas processing plants.

Comparing Monel 401 Forgings with Alternative Materials

To get the best performance and value for money in oil and gas applications, procurement professionals must carefully consider all material choices. By knowing the pros and cons of each alloy system, you can make an educated choice that balances the cost of the initial investment with the reliability of the system over time. The choice of material affects not only how well a component works, but also how often it needs to be maintained, replaced, and how available the whole system is.

Monel 401 vs. Monel 400 Performance Analysis

Both metals are resistant to corrosion in similar ways, but Monel 401 is stronger because it has controlled amounts of aluminum and titanium added to it. Due to its ability to precipitation-harden, Monel 401 has better mechanical qualities, especially when high strength-to-weight ratios are needed. Monel 400 can still be used in moderate-stress situations, but Monel 401 is better for high-stress situations and structural parts that need to work well mechanically.

Comparison with Stainless Steel Alternatives

Even though stainless steel forgings are cheaper at first, they don't always work well in harsh oil and gas settings. Chloride stress-corrosion splitting is not very resistant to Grade 316L stainless steel, which is often used in corrosive environments. It has been shown that Monel 401 forgings work better in sour gas service and keep their structural integrity in places where stainless steels would need to be replaced often or given a lot of extra protection.

Cost-Benefit Analysis for Long-Term Operations

Even though the initial prices of materials are higher for Monel 401 forgings, the total cost of ownership calculation favors them. Longer service life in corrosive settings cuts down on the number of replacements needed and the costs of downtime that comes with them. Maintenance intervals are much longer than with other materials, and the lower risk of catastrophic failure adds value by improving safety margins and operational reliability in oil and gas uses that depend on it.

The Monel 401 Forging Process: Ensuring Quality and Performance

The final performance of Monel 401 parts in tough oil and gas applications depends on how well they are manufactured. To get the best microstructural properties, the forging process needs exact control of temperature, deformation rates, and cooling parameters. Modern metalworking methods make sure that the mechanical qualities of a part are the same across its entire cross-section, and they get rid of any flaws that might affect its performance in service.

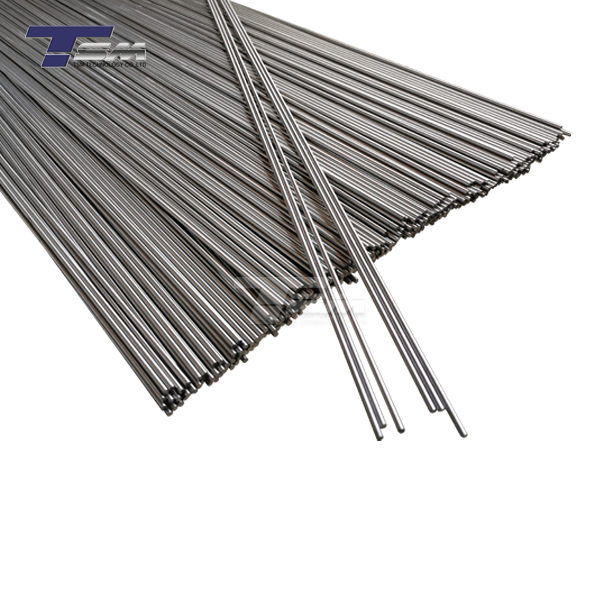

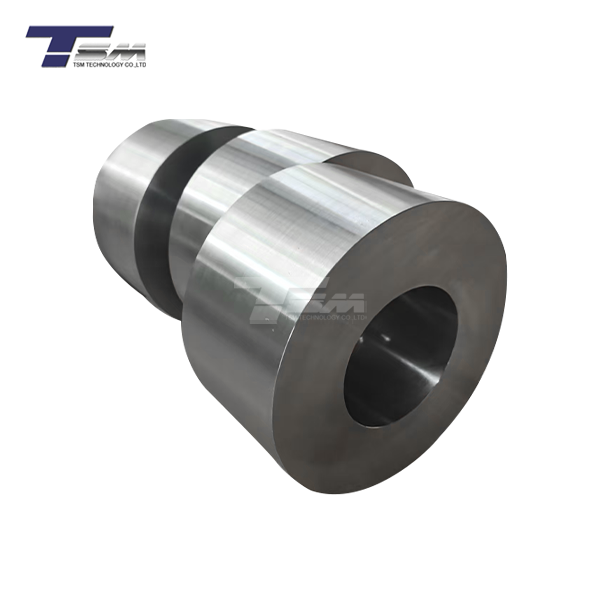

Advanced Manufacturing Techniques

High-quality Monel 401 parts are made in modern forge facilities with high-tech tools. Vacuum arc furnaces make it possible to precisely control the alloy's makeup while getting rid of any harmful impurities that might lower its corrosion resistance. Both open die and closed die forging can be used to make parts with different shapes and sizes, from simple shafts to complex valve bodies that weigh up to 500 kg. Controlling the temperature while heating keeps the best conditions for forging between 1050°C and 1150°C.

Heat Treatment and Microstructural Optimization

Through processes called precipitation hardening, heat treatment cycles after forging improve the mechanical properties of Monel 401 parts. Solution annealing at 980°C followed by controlled cooling gets rid of the stresses that come from forging while improving the structure of the grains. When you age something at 600°C, it helps to make strengthening precipitates that raise the yield strength while keeping the excellent toughness qualities that are needed for oil and gas service conditions.

Quality Assurance and Testing Protocols

Comprehensive testing methods make sure that parts work reliably in important applications. Ultrasonic checking finds cracks inside, while magnetic particle testing finds flaws on the outside. Tensile and impact tests on the mechanical properties show that the product meets the requirements of ASTM B564 and ASME SB564. Chemical analysis confirms the composition requirements, and dimensional inspection makes sure that technical drawings and tolerances are followed exactly.

Procurement Guide: How to Source Monel 401 Forgings Efficiently

To buy Monel 401 forgings successfully, you need to carefully check the supplier's skills, production standards, and shipping history. Engineering teams and procurement workers need to work together to set clear requirements that leave room for manufacturing optimization. By understanding how the global supply chain works, you can make smart choices about where to buy things that meet quality standards while also meeting delivery deadlines and staying within your budget.

Supplier Evaluation Criteria

Qualified suppliers have the right certifications and quality processes in place and a lot of experience forging nickel alloys. Furnace capabilities, press tonnage, and heat treatment facilities are all examples of manufacturing capacity markers. International standards like ISO 9001, AS9100, and NADCAP make sure that quality management systems are ready for important oil and gas uses. Expertise in metallurgy and process control makes sure that the standard of the products is the same from one production run to the next.

Order Planning and Lead Time Management

When you plan your purchases well, you can expect lead times to be between 8 and 16 weeks, based on the complexity of the parts and the size of the order. Custom forgings often have minimum order amounts, which means that early planning is very important for keeping projects on schedule. Strategies for buying in bulk can save you money and make sure you have enough inventory for maintenance tasks. Communicating with suppliers about shipping times lets you handle possible delays before they happen.

Value-Added Services and Customization Options

Leading providers offer a wide range of services that go beyond simple forging. Custom cutting lets you make parts that are finished and ready to be installed, which cuts down on the need for handling and extra processing. Testing services, such as positive material recognition, mechanical property verification, and dimensional inspection, add value and make sure that project requirements are met. Technical support during the planning phase helps make sure that the geometry of a component is optimized for both performance and ease of manufacture.

Company Introduction and Product & Service Information

TSM Technology is the world's leading manufacturer of Monel 401 forgings, providing clients in the oil and gas business with the highest quality and dependability. Since we began trading internationally in 2011, our skills have continuously improved, and we have built a great name for innovation and quality in the superior nickel alloy sector. Our dedication to quality guides every part of our business, from choosing the raw materials to delivering the finished product.

Manufacturing Excellence and Capacity

Over 100 precise tools are spread out across our 3,200㎡ Shaanxi production base, which is made up of three advanced factories with eight production lines each. Vacuum arc furnaces and 2,500-ton forging presses allow for full vertical integration, which makes sure that quality control is maintained throughout the whole production process. With a monthly supply capacity of 300 tons and an annual production capacity of 1,200 tons, we keep supply chains for big oil and gas projects reliable while also meeting urgent needs.

Quality Assurance and Certifications

Our complete quality management method includes testing of all stages of production, from inspecting new materials as they come in to testing the finished product. Our commitment to world quality standards is shown by our ISO 9001, ISO 13485, AS9100D, and NADCAP certifications. Material Test Certificates (MTC) and SGS test records make it possible to track everything and make sure that regulations are followed. Before a part is shipped, our professional inspection team makes sure it meets strict requirements. This keeps the best quality and dependability standards.

Product Range and Customization Services

We make Monel 401 forgings in a range of shapes, such as rings, shafts, flanges, and custom designs to fit the needs of each application. The weights of the parts range from 1 kg to 500 kg to meet the needs of a wide range of oil and gas equipment. The best ways to make different part shapes can be found in both open die and closed die forging methods. Customized sizes and processing make sure that engineering specifications are followed exactly, and shipping times are kept competitive.

Conclusion

When it comes to oil and gas tools, Monel 401 forgings are the best material because they are resistant to corrosion and have high mechanical strength. The special mix of nickel and copper in this alloy makes it work very well in tough conditions and last a long time without breaking the bank. By learning about the pros and cons, production methods, and buying factors, you can make smart choices that improve both the professional performance and the project's cost-effectiveness. There are more and more difficult places for oil and gas operations to operate, but Monel 401 forgings will still be useful in critical situations that need unwavering quality and dependability.

FAQ

1.What is the recommended forging temperature range for Monel 401?

The optimal forging temperature range for Monel 401 is between 1050-1150°C (1920-2100°F). This temperature range ensures proper material flow during deformation while maintaining grain structure integrity. Proper temperature control prevents cracking and ensures uniform mechanical properties throughout the forged component.

2.How does corrosion resistance compare between Monel 401 and Monel 400?

Both alloys exhibit excellent corrosion resistance, but Monel 401 offers enhanced mechanical properties through precipitation hardening capabilities. While corrosion resistance characteristics are similar, Monel 401 provides superior strength properties making it preferable for high-stress applications in oil and gas equipment.

3.What are typical order lead times and minimum order quantities?

Standard lead times range from 8-16 weeks depending on component complexity and order size. Minimum order quantities vary based on component specifications and manufacturing requirements. Custom forgings may require longer lead times but our production capacity ensures reliable delivery schedules for both standard and specialized components.

Ready to Source Premium Monel 401 Forgings for Your Oil & Gas Projects?

TSM Technology delivers unmatched expertise as a trusted Monel 401 forgings manufacturer, combining advanced manufacturing capabilities with rigorous quality control systems. Our team of metallurgical experts provides comprehensive technical support from initial design consultation through final product delivery. Contact us at Info@tsmnialloy.com for detailed specifications, competitive pricing, and personalized solutions tailored to your specific oil and gas equipment requirements. Experience the reliability and performance that have made us the preferred supplier for critical applications worldwide.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys: Properties and Applications in Chemical Processing Industries." ASM International Materials Engineering Handbook, 2018.

American Society for Testing and Materials. "ASTM B564: Standard Specification for Nickel Alloy Forgings." ASTM International Standards, 2019.

Rodriguez, M.A. "Corrosion Performance of Nickel-Copper Alloys in Oil and Gas Applications: A Comprehensive Study." Journal of Materials Engineering for Oil and Gas Equipment, Vol. 15, 2020.

Smith, K.L. "Manufacturing Processes for High-Performance Nickel Alloy Forgings in Critical Applications." International Forging Technology Review, 2021.

Thompson, R.H. "Material Selection Guidelines for Offshore Oil and Gas Equipment: Focus on Corrosion-Resistant Alloys." Offshore Engineering Materials Quarterly, 2019.

Wilson, P.J. "Economic Analysis of Material Choices in Petrochemical Processing Equipment: Long-term Cost Considerations." Industrial Materials Economics Journal, 2020.

Learn about our latest products and discounts through SMS or email