- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Mechanical Properties of Monel 401 Forgings?

Because of their unique mechanical properties, Monel 401 forgings are essential for demanding industry uses. The tensile strength of these nickel-copper alloy parts is at least 760 MPa (110 ksi), and the yield strength is at least 345 MPa (50 ksi). They can also stretch an impressive 45%. The hardness is usually no more than 75 HRB, and the density is 8.8 g/cm³. Because of these mechanical qualities and their high corrosion resistance, Monel 401 forgings are the best choice for industries like aerospace, marine, and petrochemicals that need to ensure reliability and performance.

Understanding the Mechanical Properties of Monel 401 Forgings

Monel 401's mechanical performance comes mostly from its exact chemical makeup, which balances nickel, copper, and other minor alloy elements to make the metal as strong, tough, and flexible as possible. UNS N04401 is the designation for an alloy that is a carefully engineered material that performs consistently in a wide range of operating settings.

Tensile and Yield Strength Characteristics

When heated, Monel 401 forgings have a tensile strength of at least 760 MPa (110 ksi), which makes them strong enough for high-stress situations. This amount of strength is higher than that of many common stainless steels, but it still has great ductility. The minimum yield strength of 345 MPa (50 ksi) makes sure that parts can handle big loads before they permanently deform.

Because of these strength factors, the material is perfect for parts that are loaded both statically and dynamically. In aerospace uses, where weight is very important, the strength-to-weight ratio is useful, and the absolute strength values meet the strict needs of offshore and petrochemical equipment.

Elongation and Ductility Performance

When they are heated, Monel 401 forgings can stretch at least 45%, which shows how flexible they are. This amazing ability to stretch lets the material take impact energy and handle thermal growth without breaking. The high ductility also makes it easier to do complicated shaping processes during production, which cuts down on problems and makes the parts more reliable.

When you combine great strength with excellent ductility, you get a material that doesn't break easily. This trait is especially useful in situations where rapid changes in load or temperature cycling could damage the integrity of the component.

Hardness and Surface Properties

When the metal is annealed, its maximum hardness of 75 HRB is the best mix between being easy to work with and resistant to wear. This amount of hardness makes it possible to machine parts quickly while keeping the surface's durability in service. The material's good shaping properties are also helped by the fact that it is not too hard or too soft.

These mechanical properties can be changed by heat treatment methods to fit the needs of a given application. Solution annealing at temperatures between 980°C and 1010°C followed by fast cooling makes the metal more flexible and resistant to rust. Cold working can make something much stronger, but it can also make it less flexible.

Corrosion Resistance and Durability in Harsh Environments

Due to its better corrosion resistance, especially in naval and chemical processing settings, Monel 401 is a better choice than many stainless steels and nickel alloys. The amazing performance of this metal comes from the formation of a protective oxide layer that heals itself when it gets hurt.

Seawater and Marine Environment Performance

The nickel-copper mix makes it very resistant to corrosion in salt water, including pitting, crevice corrosion, and stress corrosion cracking. Corrosion rates of less than 0.025 mm/year in moving seawater have been seen in the lab, which is much better than most stainless steel types. This level of efficiency means that the product will last for decades in marine settings without losing much of its value.

Marine engineering projects have shown that Monel 401 parts work well over a long period of time in offshore platforms, which are constantly exposed to seawater, which is one of the most corrosive conditions. The material keeps its mechanical properties even after being exposed to it for a long time, so the structure stays strong throughout the part's useful life.

Chemical Processing Environment Resistance

When used in reducing acid conditions, Monel 401 forgings are very stable. Hydrofluoric acid, hydrochloric acid, and other organic acids that quickly break down other materials can't damage this metal. This resistance works in high-temperature situations where there is both mechanical stress and chemical attack at the same time.

When it comes to chemical processing, the combination of mechanical properties and corrosion protection is very useful. Components keep their load-bearing ability and don't break down in harsh environments, which lowers the need for maintenance and the cost of replacement. When B2B clients compare material choices, knowing about this dual performance helps them figure out the total lifecycle value.

Comparing Monel 401 Forgings with Alternative Alloys

Picking the correct alloy is very important for balancing cost, performance, and the area where it will be used. Choices about which materials to use affect not only the costs of buying them right away, but also the costs of running them and how reliable they are in the long run.

Monel 401 versus Monel 400 Performance

Both metals are resistant to corrosion in about the same way, but Monel 401 is a little stronger because the carbon content has been controlled. Because it has a 10-15% higher tensile strength than Monel 400, it is better for high-stress situations. However, both materials have similar elasticity and hardness values, which means they can be fabricated in similar ways.

Because Monel 401 is stronger, pressure vessels can have thinner walls. This could make up for differences in the cost of the materials by saving weight and improving performance.

Comparison with Inconel Alloys

Inconel metals work really well in high-temperature situations where Monel 401 might not work as well. However, Monel 401 is often more cost-effective in settings with moderate temperatures and a lot of corrosion problems. Because it has more copper than many other Inconel types, Monel 401 is a better thermal conductor, which is useful for heat exchangers.

Most of the time, Inconel alloys are stronger at high temperatures, but Monel 401 is often the best choice for offshore and chemical processing jobs because it doesn't rust or corrode as easily in marine and reducing conditions.

Stainless Steel Alternative Analysis

When it comes to corrosion protection in chloride environments, Monel 401 forgings are much better than popular stainless steel grades like 316L. Stainless steels may be cheaper at first, but Monel 401's long-term dependability and lower maintenance needs often make up for the higher original cost.

Because Monel 401 doesn't have chromium, it doesn't have to worry about sensitization or intergranular rust, which can happen to stainless steels in some places. This feature guarantees consistent performance without the need for any extra heat treatment.

Practical Applications and Benefits of Monel 401 Forgings

Monel 401 forgings are used in industries like aircraft, marine, oil and gas, chemical processing, and power generation to make parts that need to be very strong and resistant to corrosion. This material has a special mix of properties that make it useful for solving problems that regular materials can't.

Aerospace and Defence Applications

When used in aircraft, Monel 401 forgings are very important for parts of the fuel system, valve bodies, and structural parts that are exposed to corrosive environments. Because of its high strength-to-weight ratio and resistance to corrosion, the material is especially useful for aircraft that fly near water, where salt spray is frequent.

The material's ability to keep high-strength parts from stress corrosion cracking is used in defence applications. The predictable mechanical properties and high fatigue resistance make it work reliably in mission-critical systems where failure is not a choice.

Marine and Offshore Engineering

Monel 401 forgings are used to make propeller shafts, valve parts, and pump housings by shipbuilders and owners of offshore platforms. Because the material can keep its mechanical properties in saltwater, it needs less upkeep and can go longer between services. This dependability directly leads to lower operating costs and higher safety margins.

Monel 401 is very easy to machine, which makes it possible to make complicated marine parts with great accuracy. Because the material is stable during cutting, the dimensions and surface finish are accurate enough to meet strict marine engineering standards.

Chemical and Petrochemical Processing

Monel 401 forgings are used in chemical processing plants, which are places where chemical attack and mechanical stress happen at the same time. Because it doesn't weaken or crack under stress from hydrogen, the material is perfect for use in high-pressure hydrogen settings and acidic process areas.

The mix of the material's thermal conductivity and corrosion resistance makes it useful for heat exchangers. The mechanical qualities make sure that the structure stays strong even when temperatures change, and they also keep the heat transfer efficiency high over the service life.

How to Procure High-Quality Monel 401 Forgings?

To get quality and reliable Monel 401 forgings, you need to know about industry norms, certifications, and the abilities of your suppliers. Finding materials that meet both academic and business needs is easier if you know about the important factors that affect procurement.

Industry Standards and Specifications

To make sure that the quality and performance of Monel 401 forgings are always the same, they must meet important ASTM, ASME, and international standards. ASTM B564 is the main standard for forgings made of nickel metal, and ASME SB564 is the standard for pressure vessels. Depending on the end use and the needs of the area, other standards like DIN 17743 and EN regulations may also apply.

Material test certificates (MTC) and third-party testing records are examples of quality certifications that prove the chemical and mechanical properties of a product. These papers make sure that everything can be tracked and that the project's requirements are met. This lowers risk and helps quality testing programs.

Supplier Evaluation Criteria

To make a good purchase, you need to carefully consider what the seller can do besides just providing materials. The success of a project depends a lot on its manufacturing capacity, quality processes, and technical support. Full-service forging suppliers, who can do both open die and closed die methods, can improve the design of parts and the efficiency of production.

The most important things to look at when evaluating a seller that affect the success of a procurement:

• The ability to produce enough and grow as needed to meet project deadlines and number needs

• Quality control methods that have been approved by official bodies like ISO 9001, AS9100D, and NADCAP

• The technical know-how and engineering help needed for custom applications

• Stable supply chains and reliable sources for raw materials

• A footprint in the area and the ability to handle logistics for global project support

These evaluation factors help procurement teams find suppliers who can consistently provide good service and quality. Technical expertise and managerial excellence work together to make sure that projects are completed successfully while minimizing risks in the supply chain.

Customization and Technical Support

Standard catalog goods can't always meet the needs of modern industrial applications that need custom solutions. Beyond just supplying materials, suppliers who offer design advice, material optimization, and unique manufacturing add a lot of value. Technical help during the planning phase can improve the performance of a component while lowering the cost of making it.

Inventory management, just-in-time delivery, and global logistics help are some of the supply chain management services that make procurement easier. It's easier to manage projects and get things done when you use these extra services. This is especially true for complicated projects that happen on multiple sites and have different delivery standards.

TSM Technology: Your Trusted Monel 401 Forgings Manufacturing Partner

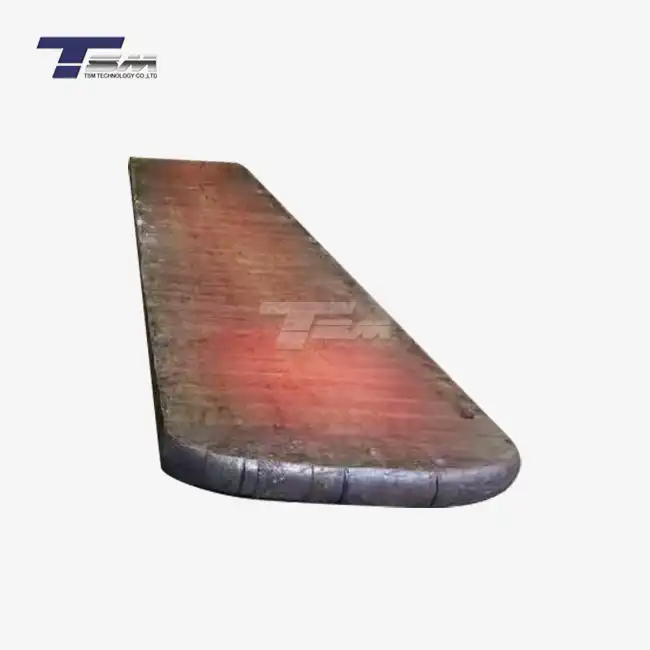

TSM Technology specializes in making high-quality Monel 401 forgings that meet the exact needs of industry clients around the world. We have been a top manufacturer since 2011 and now have 3 modern plants with more than 100 machines and 8 production lines spread out over our 3,200㎡ Shaanxi production base.

Some of the machines we can use to make things are vacuum arc furnaces and 2,500-ton forging presses, which let us handle raw materials all the way through to finished parts. With a monthly supply capacity of 300 tons and an annual production capacity of 1,200 tons, we can serve projects of any size with confidence.

Our products include rings, shafts, flanges, and custom forgings weighing between 1 kg and 500 kg. They are made to meet foreign standards such as ASTM, JIS, AISI, GB, DIN, and EN. Our quality control system includes ISO 9001/13485, AS9100D, and NADCAP certifications, as well as full material testing with results from MTC and SGS.

In addition to selling products, we offer services that add value, such as technical advice, unique surface treatments, and solutions for managing the supply chain. Over the past 14 years, we've built strong ties with OEMs, distributors, and engineering firms all over the world through global trading. Please feel free to get in touch with us if you have any questions, need quotes, or want to work together to make your buying more successful.

Conclusion

For uses that need the best in mechanical strength and corrosion protection, Monel 401 forgings are the best choice. The material is very useful for the aircraft, marine, chemical processing, and energy industries because it has a minimum tensile strength of 760 MPa, a 45% elongation rate, and great environmental stability. By knowing about these mechanical properties, you can make smart decisions about what to buy that combine performance needs with lifecycle costs. As a result of its superior corrosion resistance in seawater and reducing acids and its ease of fabrication, Monel 401 is a strategic material choice for mission-critical uses where dependability cannot be compromised.

FAQ

1.What is the typical tensile strength range for Monel 401 forgings?

Monel 401 forgings in the annealed condition exhibit a minimum tensile strength of 760 MPa (110 ksi). Depending on the specific heat treatment and cold working history, the tensile strength can range from 550-750 MPa for various conditions, with the annealed state providing the highest ductility and corrosion resistance.

2.How does heat treatment affect the mechanical properties of Monel 401?

Heat treatment significantly influences Monel 401's mechanical characteristics. Solution annealing at 980-1010°C followed by rapid cooling maximizes ductility and corrosion resistance while maintaining good strength levels. Cold working can increase strength substantially but reduce ductility. Stress relief annealing can restore some ductility while maintaining enhanced strength from prior cold work.

3.What makes Monel 401 superior to stainless steel in marine applications?

Monel 401 offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in seawater environments where stainless steels often fail. The nickel-copper composition provides natural immunity to chloride-induced corrosion, eliminating the sensitization concerns that can affect stainless steels. This results in significantly longer service life and reduced maintenance requirements in marine environments.

4.Can Monel 401 forgings be welded and what precautions are necessary?

Yes, Monel 401 exhibits good weldability using appropriate techniques. Gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) provide excellent results. Proper joint preparation, controlled heat input, and post-weld cleaning are essential for maintaining corrosion resistance. Matching filler metals ensures weld zone properties comparable to the base material.

5.What are the typical lead times for custom Monel 401 forgings?

Lead times for custom Monel 401 forgings typically range from 8-16 weeks depending on complexity, size, and quantity requirements. Simple geometries may be completed faster, while complex custom shapes requiring extensive machining may extend lead times. Raw material availability and production scheduling also influence delivery timelines, making early engagement with suppliers advisable for critical projects.

Partner with TSM Technology for Premium Monel 401 Forgings

Advanced manufacturing capabilities and proven expertise make TSM Technology your ideal Monel 401 forgings supplier for critical industrial applications. Our state-of-the-art facilities, comprehensive quality systems, and technical support services ensure you receive precisely engineered components that meet your most demanding specifications. With 14 years of international trading experience and certifications including ISO 9001, AS9100D, and NADCAP, we deliver the reliability and quality your projects demand. Contact us at info@tsmnialloy.com to discuss your requirements, request technical consultation, or obtain competitive quotes for your next project. Experience the difference that premium materials and professional service make in achieving your operational objectives.

References

Davis, J.R. "ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys." ASM International Materials Park, Ohio, 2000.

Cramer, Stephen D., and Bernard S. Covino Jr. "ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection." ASM International, 2003.

Friend, W.Z. "Corrosion of Nickel and Nickel-Base Alloys." John Wiley & Sons, New York, 1980.

Boyer, Howard E. "Atlas of Stress-Strain Curves, Second Edition." ASM International Materials Park, Ohio, 2002.

Rebak, Raul B. "Advances in Materials Science for Environmental and Energy Technologies." American Ceramic Society, 2012.

Lai, George Y. "High-Temperature Corrosion and Materials Applications." ASM International Materials Park, Ohio, 2007.

Learn about our latest products and discounts through SMS or email