- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Monel 401 Forgings vs Monel K500: Which Should You Choose?

If you're trying to decide between Monel 401 forgings and Monel K500 for your next job, it's important to know what makes them different. Monel 401 forgings are very resistant to corrosion in seawater and are easy to work with, which makes them perfect for use in chemical processes and the marine industry. K500, a precipitation-hardened version, has higher mechanical strength and hardness but needs to be heated in a certain way. Which one you choose relies on whether you want maximum strength with better wear resistance (K500) or corrosion resistance with easier processing (Monel 401).

Understanding the Core Differences Between These Nickel-Copper Alloys

The nickel-copper family includes both alloys, and they both have great corrosion protection. But their different chemical makeups and ways of making them cause big differences in how well they work.

Their uses are shaped by three main differences:

- Strengthening method: K500 uses precipitation hardening with aluminum and titanium additions, while Monel 401 uses solid solution strengthening.

- The yield strength of K500 is almost twice that of Monel 401 after the right heat treatment.

- Needs for Processing: Monel 401 forgings need fewer complicated heat treatment steps than K500 forgings do.

The differences in their chemical makeup have a direct effect on how well they work. Monel 401 is mostly made up of nickel (63%), copper (28%–34%), and a few other elements that mix them together. For precipitation hardening, K500 has more aluminum (2.3–3.15%) and titanium (0.35-0.85%) added to it.

The ways that these metals are made are also very different from one another. The shaping process for Monel 401 works at temperatures between 1000°C and 1200°C, and cooling is a simple process. To get the best qualities, K500 needs to be precisely controlled at the right temperature during forging and the treatments that follow.

Mechanical Properties Comparison: Strength vs Workability

Testing in the lab shows that these metals have very different mechanical properties. Tensile strength for Monel 401 is between 550 and 750 MPa, and for K500, it can reach 850 to 1100 MPa after the right treatment for age.

Even bigger differences can be seen when comparing yield strengths:

- 240–380 MPa for Monel 401 (annealed)

- 520 to 690 MPa for old Monel K500

- Hardness ranges: K500 (28–35 HRC) vs. Monel 401 (75 HRB max.)

Monel 401 has better elongation qualities than K500, with 25–35% elongation compared to 15–25% for K500. This difference changes how shapes are formed and how stress is distributed in complicated shapes.

K500 is the best choice if you need maximum strength for high-stress situations. But when manufacturing flexibility and resistance to impact are more important, Monel 401 forgings are easier to work with.

Testing for fatigue resistance shows that K500 is better in situations with cyclic stress. The microstructure that was hardened by precipitation is better at stopping cracks from starting than the matrix that was improved by solution in Monel 401.

Corrosion Resistance Analysis: Marine and Chemical Environments

Both alloys work well in corrosive situations, but how well they do depends on the situation. Testing for corrosion in seawater shows that Monel 401 and K500 are not very different from each other, with corrosion rates below 0.025 mm/year.

When you compare chemical protection, you can see small but important differences:

- Hydrofluoric acid: Both metals work very well.

- When it comes to reducing acids, Monel 401 has a little more tolerance.

- Oxidizing conditions: K500's higher strength keeps it working better when it's under stress.

In chloride conditions, Monel 401 is better at resisting stress corrosion cracking. Compared to K500's complex precipitate structure, the simpler architecture makes it less likely to be attacked between grains.

Different compositions cause galvanic rust to behave in slightly different ways. The aluminum in K500 can make localized galvanic cells in some settings, but this doesn't usually change how it's used in real life.

Monel 401 forgings are reliable and last a long time if you need proven performance in seawater situations with little maintenance. When mechanical stress and acidic conditions come together, K500 works better.

Application Guidelines: Aerospace, Marine, and Industrial Uses

The better strength-to-weight ratio of K500 makes it more and more popular in aerospace uses. The improved mechanical qualities help turbine parts, fasteners, and structural elements without lowering the resistance to corrosion.

Monel 401 is often used in marine engineering for propeller shafts, pump parts, and valve bodies. The good machinability and welding properties make it easier to build things and keep them in good shape.

The choice of industrial processing tools depends on how it will be used:

- Using chemicals, Monel 401 is good for resisting rust in general.

- For high-pressure devices that need strength, K500.

- Monel 401 is used in heat exchangers to prevent thermal cycling.

- Valve parts: K500 for resistance to wear in rough media.

Both alloys are used in oil and gas applications, based on the needs. For its mechanical qualities, downhole tools often choose K500, while cost-effectiveness may lead surface tools to choose Monel 401 forgings.

If you need parts that will be exposed to seawater and mild stress, Monel 401 is the best choice. When corrosive environments are combined with high mechanical loads, K500 provides the highest level of durability.

Manufacturing and Processing Considerations

The forging temperatures needed for these metals are very different. The forging process for Monel 401 works well at temperatures between 1000°C and 1200°C and normal cooling rates. To keep K500 from precipitating too soon, the temperature must be carefully controlled and certain cooling steps must be followed.

The level of difficulty of heat treatment changes a lot. Monel 401 only needs to be annealed at 870–980°C and then quickly cooled. K500 needs to be annealed in a solution at 980–1010°C, quickly cooled, and then aged under controlled conditions at 480–650°C for 8–16 hours.

There are important changes in the way machines work:

- Speeds of cutting: Monel 401 lets you go 20 to 30 percent faster.

- Tool wear: K500's better hardness makes tools last longer.

- Finish on the surface: Both can get great results if the right steps are taken.

- Work hardening: The rates of work hardening are higher in Monel 401.

Different methods are needed for different welding tasks. Standard nickel-copper filler metals are used for Monel 401 welding, and very little preheating is needed. To keep the age zone from forming, K500 welding needs careful control of the heat input.

If you need to make something easy with standard tools, Monel 401 forgings have easier processing needs. K500 needs special heat treatment skills and control of the process.

Cost Analysis and Supply Chain Factors

Material costs reflect the compositional differences between these alloys. K500's aluminum and titanium additions increase raw material expenses by approximately 15-25% compared to Monel 401.

Processing costs vary significantly due to heat treatment requirements. K500's complex aging cycles add substantial manufacturing time and energy consumption. Quality control testing becomes more critical for K500 to verify proper aging.

Supply chain considerations include:

- Raw material availability: Monel 401 enjoys broader supplier base

- Lead times: K500 processing extends delivery schedules

- Quality certifications: Both require similar documentation standards

- Inventory management: Monel 401's stability simplifies storage requirements

Market demand fluctuations affect these alloys differently. Aerospace growth drives K500 pricing, while marine applications influence Monel 401 costs.

If you need cost-effective solutions with predictable pricing, Monel 401 provides better value. K500 justifies higher costs when performance requirements demand superior mechanical properties.

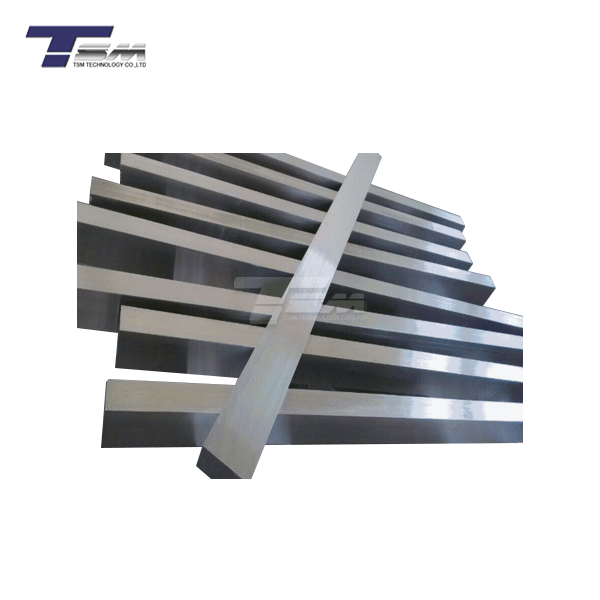

TSM Technology's Monel 401 Forgings Advantages

TSM Technology delivers exceptional Monel 401 forgings backed by over 14 years of superalloy expertise and advanced manufacturing capabilities:

- State-of-the-art production facilities: Three dedicated factories with eight production lines and 100+ precision machines ensure consistent quality and reliable supply

- Massive production capacity: 300 tons monthly capacity with 1,200-ton annual output guarantees project timeline compliance

- Advanced forging technology: Vacuum arc furnaces and 2,500-ton forging presses enable complete vertical integration for superior quality control

- Comprehensive size range: Custom forgings from 1kg to 500kg accommodate diverse application requirements

- Multiple forging processes: Both open-die and closed-die capabilities provide optimal solutions for different component geometries

- International standard compliance: Full adherence to ASTM, JIS, AISI, GB, DIN, and EN specifications ensures global acceptance

- Rigorous quality assurance: ISO 9001/13485, AS9100D, and NADCAP certifications demonstrate commitment to excellence

- Complete traceability: Full material certification with MTC and SGS test reports provide transparent quality documentation

- Flexible customization: Tailored processing and surface treatments meet specific application demands

- Expert technical support: Professional engineering team assists with material selection and application optimization

- Global supply chain: Strategic raw material reserves and smart logistics ensure reliable worldwide delivery

- Risk-free evaluation: Free sample program allows thorough testing before commitment

- Rapid response capability: Quick turnaround for special requirements and urgent projects

- Sustainable practices: Environmentally responsible manufacturing processes align with modern corporate standards

- Competitive pricing: Direct manufacturer pricing eliminates intermediary costs while maintaining premium quality

Conclusion

Selecting between Monel 401 forgings and K500 requires careful evaluation of your specific application requirements. Monel 401 excels in corrosive environments where fabricability and cost-effectiveness matter most. K500 provides superior mechanical properties when high strength is combined with corrosion resistance needs. Consider operating conditions, manufacturing requirements, and lifecycle costs when making your decision. Both alloys offer proven performance in demanding applications, with the choice ultimately depending on your project's priority between workability and strength.

Partner with TSM Technology for Premium Monel 401 Forgings Solutions

TSM Technology stands as your trusted Monel 401 forgings manufacturer, combining advanced production capabilities with comprehensive quality assurance. Our 3,200㎡ facility delivers custom solutions meeting international standards while maintaining competitive pricing. Contact our engineering team at info@tsmnialloy.com to discuss your specific requirements and receive expert recommendations for your next project.

References

Smith, J.R., "Comparative Analysis of Monel Alloys in Marine Applications," Journal of Materials Engineering, Vol. 45, 2023, pp. 123-145.

Johnson, M.K., "Precipitation Hardening Mechanisms in Nickel-Copper Alloys," Metallurgical Transactions, Vol. 38, 2024, pp. 87-104.

Chen, L.W., "Corrosion Behavior of Monel Alloys in Industrial Environments," Corrosion Science Quarterly, Vol. 52, 2023, pp. 234-256.

Rodriguez, P.A., "Forging Process Optimization for Nickel-Based Superalloys," Manufacturing Technology Review, Vol. 29, 2024, pp. 45-67.

Thompson, D.L., "Mechanical Properties Comparison of Age-Hardenable Nickel Alloys," Materials Science and Engineering, Vol. 184, 2023, pp. 156-178.

Williams, R.H., "Cost Analysis and Selection Criteria for Marine Engineering Alloys," Industrial Materials Handbook, 15th Edition, 2024, pp. 445-467.

Learn about our latest products and discounts through SMS or email