- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Screws vs Stainless Steel Screws: Which Performs Better?

When deciding between nickel screws and stainless steel screws, it depends on the application. Nickel screws work great in places with very high or low temperatures and are very good at resisting corrosion from harsh chemicals. This makes them perfect for use in aircraft, petrochemical, and marine settings. While stainless steel screws are suitable for most tasks and are less expensive, nickel-based fasteners are the most reliable in harsh environments where other materials fail. In the end, the choice comes down to finding a balance between performance needs and price concerns.

Understanding the Core Differences Between Nickel and Stainless Steel Fasteners

The main difference between these two groups of materials is their chemical make-up and the qualities that come from it. Nickel screws have a lot of nickel in them - often 70% or more - while stainless steel has only 8–20% nickel mixed in with chromium and iron.

Their success is shaped by three main differences:

- Temperature Resistance: Nickel metals stay structurally sound at temperatures above 1,000°C, while regular stainless steel starts to lose its strength around 400-600°C.

- How Corrosion Works: Some types of corrosion, like stress-corrosion cracking, can damage stainless steel, but nickel-based materials don't get damaged by them.

- When it comes to magnetic properties, pure nickel screws are not magnetic, but many types of stainless steel are.

Nickel-based screws are better for use in places with harsh chemicals or high temperatures where fixings need to be strong. However, stainless steel screws may be enough if you need cost-effective options for normal situations.

Performance Analysis in Extreme Environments

In the real world, tests show that these materials don't work as well as each other when conditions are tough. New research done on offshore platforms shows that nickel metal fasteners don't need to be replaced for 15 to 20 years, but stainless steel screws do need to be replaced every 5 to 7 years in the same saltwater environment.

Even bigger differences can be seen in temperature performance data:

- At 500°C, monel screws are still 80% as strong as they are at room temperature.

- At the same temperature, 316L stainless steel screws only keep 60% of their strength.

- Up to 650°C, Inconel 625 screws don't lose much of their strength.

Marine engineers regularly say that nickel-based fasteners work better in saltwater environments. Nickel metals are better protected against chloride-induced corrosion than stainless steel alternatives because they form a passive oxide layer.

Nickel screws provide better long-term dependability if you need fasteners for subsea equipment or high-temperature industrial processes.

Corrosion Resistance Comparison

Knowing how rust works helps engineers choose the right materials. Screws made of stainless steel are protected by chromium oxide films, but these films can break down in some places. Nickel screws make protective layers that are more stable and can stand up to strong media.

Some of the most important benefits of nickel-based fasteners for corrosion protection are:

- Stress-corrosion cracking from chloride: almost resistant compared to stainless grades that are more likely to crack.

- Acidic Environments: Better protection against sulfuric and hydrochloric acids.

- Conditions that are alkaline: Works very well in acid solutions.

- When combined with other nickel metals, it has better galvanic compatibility and less galvanic corrosion.

In the lab, Hastelloy C-276 screws were exposed to 30% hydrochloric acid for more than 1,000 hours without showing any signs of rust. Under the same conditions, samples of equivalent 316L stainless steel showed large damage within 48 hours.

When you need fixings for chemical processing equipment or harsh industrial settings, nickel alloy screws are the best way to keep them from breaking too soon.

Mechanical Properties and Strength Characteristics

The ratios of strength to weight are very different between these groups of materials. Nickel-based superalloys have very good mechanical qualities because they are carefully mixed and heated.

Comparative research on tensile strength shows:

- Inconel 718 has a maximum tensile strength of 1,240 to 1,380 MPa.

- 316L stainless steel has a maximum tensile strength of 520 to 670 MPa.

- When aged, Monel K-500 can withstand 1,100 MPa or more.

Engineers can specify smaller fastener sizes while keeping the same clamping force thanks to the superior mechanical properties of nickel screws. In aerospace uses, where every gram counts, this weight loss is very important.

Testing for fatigue resistance shows that nickel metal fasteners can withstand 10 cycles of stress levels that would break stainless steel screws in 10 cycles. This longer fatigue life cuts down on the number of repair visits and makes the system more reliable.

Nickel screws offer better performance characteristics if you need fasteners for high-stress applications or designs that are sensitive to weight.

Cost-Benefit Analysis for Industrial Applications

Even though nickel screws are more expensive, they are often better in difficult situations because they have a lower total cost of ownership. The initial cost of materials is 3–8 times higher than those made of stainless steel, but the benefits over time make up for this.

Nickel screws are more cost-effective because:

- Longer Service Life: 2 to 4 times longer between replacements

- Less downtime: fewer repair breaks to replace fasteners

- System Reliability: Less likely that a major fastener failure will happen

- Weight Savings: Possible reductions in structural weight in aircraft uses

Over a 10-year service term, offshore platform operators say that using Monel fasteners instead of 316L stainless steel screws cuts maintenance costs by 60%. The harsh marine climate speeds up the corrosion of stainless steel, so it needs to be replaced often.

To meet strict weight and performance requirements, aerospace makers are choosing titanium or nickel-based fasteners more and more. When spread out over aircraft service lifetimes of more than 20 years, the material cost premium becomes almost nothing.

If you need bolts for mission-critical tasks where failure would have major effects, nickel screws are worth the extra money because they are more reliable.

Application-Specific Recommendations

When choosing fastening solutions, different businesses put different levels of importance on different performance characteristics. Knowing these requirements helps you make better choices about what materials to use.

Uses in Aerospace and Defense

Engines in airplanes work in cycles of very high and very low temperatures that are hard on most materials. When heated to temperatures where stainless steel weakens, nickel-based superalloys stay strong and don't rust.

Nickel screws should be used for the following:

- Hardware for fixing the turbine section

- Parts of the exhaust system

- Joints in structures that are heated up

- Important hardware for flight safety

Processing of oil, gas, and petrochemicals

Fasteners are exposed to corrosive hydrocarbons, saltwater, and harsh chemicals in refineries and offshore sites. The choice of materials has a direct effect on safety and the continuation of operations.

Nickel metals are great for:

- Places where sour gas is used

- Systems with a lot of pressure and heat

- Equipment exposed to salt water

- Process equipment that works with acidic materials

Engineering for the sea and offshore

Through a combination of corrosion processes, seawater makes it hard for metal fasteners to work. In marine settings, stress corrosion cracking caused by chloride often breaks down stainless steel.

If you need fasteners for underwater gear or shipboard systems, Monel or other nickel metals are the best choice because they don't rust when exposed to saltwater.

Highlighting TSM Technology's Nickel Screws Advantages

•Advanced Manufacturing Skills: Three specialized factories with more than 70 precision tools and 8 production lines ensure consistent quality and a steady supply capacity of 100,000 to 300,000 pieces.

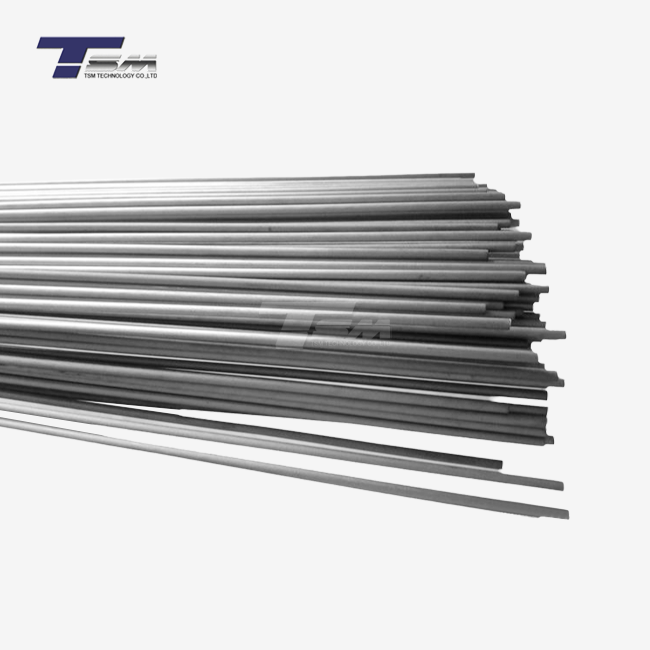

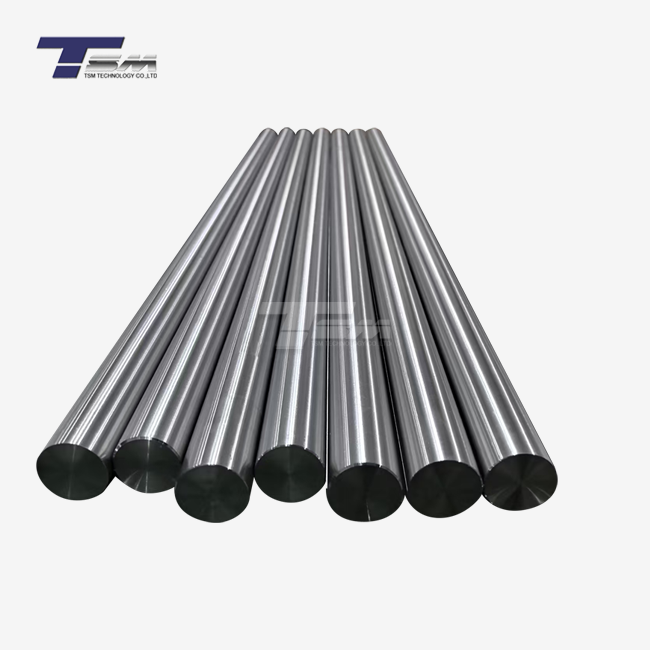

• Size of the Whole Range: Full stock of standard sizes M2.5 to M32, as well as special lengths from 1 mm to 1990 mm to meet a wide range of application needs.

• Many alloy choices: a wide range of alloys, such as Monel, Inconel, Incoloy, and Hastelloy, each designed to work in a certain way.

• Standards around the world Fully following the rules set by ASTM, DIN, JIS, BS, and GB/T; EN10204 3.1/3.2 certification is provided.

• Fast Delivery Service: Better planning of production times lets deliveries happen in 10 to 25 days, and the minimum order quantity (MOQ) can be as low as 100 pieces.

• Quality Assurance Program: strict checking procedures and reports from third parties to make sure that materials can be tracked and that they work as expected

• Custom Engineering Support: The company has an in-house technology team that can make suggestions based on the application and create custom fasteners.

• Global Supply Network: Has been trading internationally since 2011 and has a track record of dependability in the power production, aerospace, petrochemical, and marine industries.

• Free Sample Program: Giving away free samples speeds up the process of evaluating materials and getting projects approved.

• Competitive Pricing Structure: Prices directly from the manufacturer, with clear cost structures and a range of payment choices, such as T/T, L/C, and others.

• Technical Documentation: Full material certificates, mechanical property data, and application guidelines help engineers make choices.

• Long-term partnership approach: a dedicated customer support team makes sure that critical applications always have access to technical help and a reliable supply chain.

Material Selection Guidelines

To choose between nickel and stainless steel screws, you need to carefully think about how they will be used and what kind of performance you need. When engineers make choices, they should think about a lot of different things.

Criteria for evaluating the environment:

- Maximum Operating Temperature: Nickel metals work best above 400°C.

- Exposure to Corrosive Media: Nickel must be resistant to acids, chlorides, and caustic liquids.

- Stress Levels: Nickel metal strength is good for high-stress situations.

- Needs for Magnetics: Specific nickel types are needed because they are not magnetic.

Performance testing procedures help make sure that the materials chosen are correct before they are fully put into use. Accelerated corrosion testing, exposure to high temperatures, and checking of mechanical properties prove that the material is suitable for the intended uses.

Technical advice from experienced fastener makers can be very helpful if you need help choosing the right material for a certain job.

Conclusion

Comparing the performance of nickel screws and stainless steel screws makes it clear that some applications will benefit from stainless steel screws more than others. Nickel-based fasteners work great in places with high temperatures, corrosion, and a lot of stress, where the stability of the material is very important. While stainless steel screws are a good choice for moderate service conditions and don't cost much, nickel alloys are more expensive but work better and last longer in demanding situations. When engineers choose the best fastening options for their projects, they have to think about the operating conditions, performance needs, and total cost of ownership.

Partner with TSM Technology for Premium Nickel Screws Manufacturing Solutions

With 14 years of experience making high-quality alloys, TSM Technology is the company you can trust to give you nickel screws. Precision fasteners that meet the strict needs of the aerospace, petrochemical, marine, and power production industries are made in our state-of-the-art facility. Get in touch with our technical team at info@tsmnialloy.com to talk about your unique application needs and get expert material suggestions backed by full quality certifications.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International Materials Park.

Gedge, G. (2018). "Structural Marine Applications of Stainless Steel – Durability in Chloride Environments." International Stainless Steel Forum Technical Report.

Reed, R.C. (2006). The Superalloys: Fundamentals and Applications. Cambridge University Press.

Rebak, R.B. (2005). "Alloy Selection for Supercritical Water Applications." Corrosion Engineering, Science and Technology, 40(4), 293-299.

Special Metals Corporation. (2020). High-Performance Alloys for Resistance to Aqueous Corrosion. Technical Bulletin.

Tawancy, H.M., Ul-Hamid, A., & Abbas, N.M. (2004). Practical Engineering Failure Analysis. Marcel Dekker Publications.

Learn about our latest products and discounts through SMS or email