- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Monel Alloy 400: Corrosion Resistance in Challenging Environments

Monel alloy 400 stands out as a premier material for tackling corrosion in harsh environments. This nickel-copper alloy boasts exceptional resistance to a wide range of corrosive media, making it an ideal choice for industries facing aggressive chemical conditions. With its unique composition of approximately 67% nickel and 31% copper, Monel 400 exhibits remarkable strength and durability in seawater, acids, and alkaline solutions. Its versatility extends to applications in marine engineering, chemical processing, and oil and gas exploration, where its ability to withstand high temperatures and pressures is crucial. As industries continue to push the boundaries of material performance, Monel alloy 400 remains a trusted solution for ensuring longevity and reliability in the most demanding operational settings.

Composition and Properties of Monel Alloy 400

Chemical Makeup and Elemental Synergy

Monel alloy 400's composition is a carefully balanced blend of elements that contribute to its exceptional properties. The predominant components are nickel (63-70%) and copper (28-34%), which form the foundation of its corrosion resistance. Small amounts of iron, manganese, carbon, and silicon are also present, each playing a role in enhancing the alloy's overall performance. This unique elemental synergy results in a material that combines the best attributes of its constituent metals, creating a sum greater than its parts.

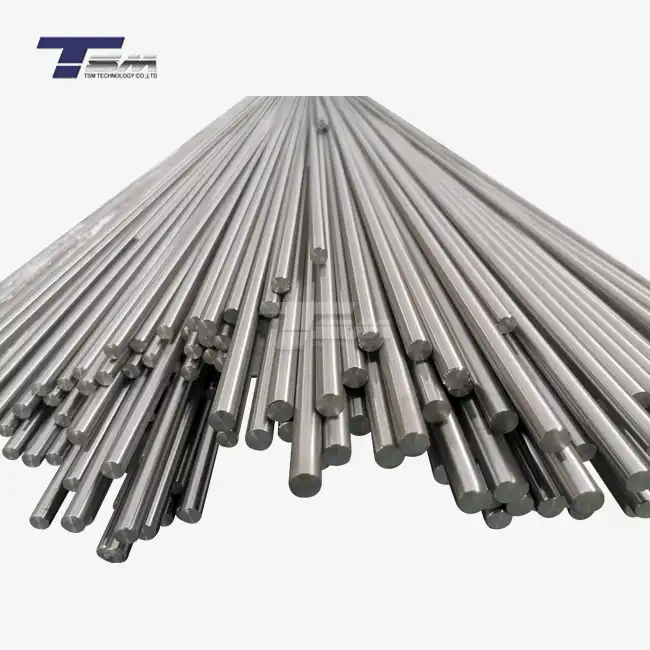

Mechanical Characteristics and Strength

The mechanical properties of Monel 400 are impressive, contributing to its widespread use in demanding applications. It exhibits high tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 585 MPa), coupled with excellent ductility. The alloy's yield strength usually falls between 25,000 and 50,000 psi (170 to 345 MPa), depending on the specific heat treatment and processing. These characteristics allow Monel 400 to maintain structural integrity under significant stress, making it suitable for components that must withstand high pressures and dynamic loads.

Thermal and Electrical Conductivity

Monel alloy 400 possesses moderate thermal conductivity, with values around 21.8 W/m·K at room temperature. This property makes it suitable for applications requiring heat transfer without compromising corrosion resistance. Additionally, its electrical resistivity of approximately 54.8 µΩ·cm allows for specific electrical applications where conductivity and corrosion resistance are both necessary. These thermal and electrical properties, combined with its strength and corrosion resistance, make Monel 400 a versatile material for various industrial uses.

Corrosion Resistance Mechanisms of Monel Alloy 400

Passivation and Oxide Layer Formation

One of the key mechanisms behind Monel alloy 400's exceptional corrosion resistance is its ability to form a protective passive layer. When exposed to oxygen or oxidizing environments, the alloy's surface reacts to form a thin, adherent oxide film. This passivation process creates a barrier that significantly slows down further corrosion. The oxide layer, primarily composed of nickel and copper oxides, is self-healing and can quickly reform if damaged, providing continuous protection against corrosive attack.

Resistance to Specific Corrosive Media

Monel 400 exhibits remarkable resistance to a wide array of corrosive substances. It performs exceptionally well in seawater and other chloride-containing environments, resisting pitting and crevice corrosion where many other materials fail. The alloy also shows excellent resistance to sulfuric and hydrofluoric acids, even at elevated temperatures. Its ability to withstand caustic solutions, including sodium and potassium hydroxides, further expands its applicability in chemical processing industries. This broad spectrum of corrosion resistance is attributed to the synergistic effect of nickel and copper in the alloy's composition.

Electrochemical Behavior in Corrosive Environments

The electrochemical behavior of Monel alloy 400 in corrosive environments contributes significantly to its durability. In many electrolytes, the alloy exhibits a noble potential, reducing its susceptibility to galvanic corrosion when coupled with other metals. This characteristic is particularly beneficial in marine applications where galvanic corrosion is a common concern. Furthermore, Monel 400's ability to maintain a stable passive layer across a wide range of pH values and temperatures ensures its corrosion resistance remains effective under varying conditions, making it a reliable choice for long-term service in aggressive environments.

Applications and Performance of Monel Alloy 400 in Challenging Environments

Marine and Offshore Industry Usage

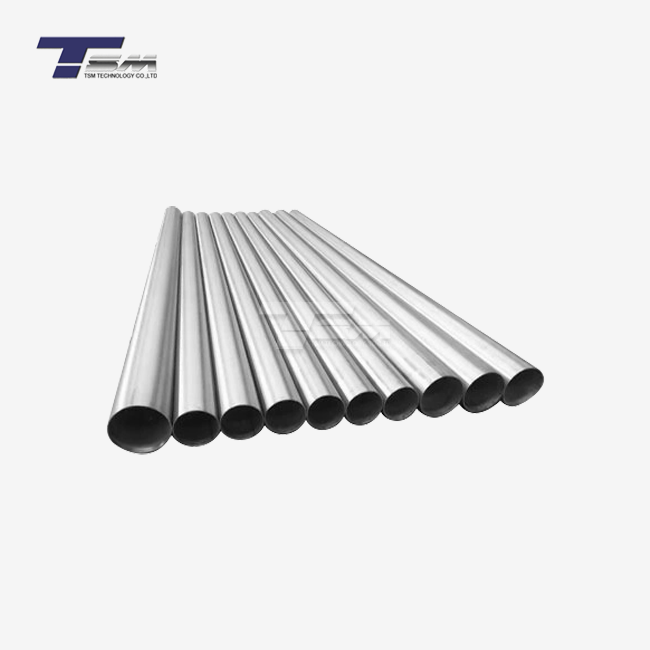

In the marine and offshore industries, Monel alloy 400 has proven its worth in numerous applications. Its excellent resistance to seawater corrosion makes it ideal for components such as pump shafts, valve stems, and heat exchanger tubes in desalination plants. Offshore oil and gas platforms utilize Monel 400 for piping systems, fasteners, and instrumentation exposed to saltwater spray and marine atmospheres. The alloy's ability to resist erosion-corrosion in high-velocity seawater flows also makes it suitable for propeller shafts and marine propulsion systems, ensuring longevity and reliability in these critical components.

Chemical Processing and Handling Equipment

The chemical processing industry heavily relies on Monel alloy 400 for equipment that handles corrosive substances. It is commonly used in reactors, heat exchangers, and storage tanks for hydrofluoric acid production and handling. The alloy's resistance to both reducing and oxidizing acids makes it valuable in the manufacturing of sulfuric acid and in processes involving organic acids. Monel 400's ability to maintain its properties at elevated temperatures also allows its use in high-temperature chemical reactions, where other materials might degrade or fail.

Specialized Applications in Extreme Conditions

Monel alloy 400 finds application in several specialized fields where extreme conditions prevail. In the aerospace industry, it is used for rocket and missile components due to its strength and corrosion resistance at high temperatures. The nuclear power industry employs Monel 400 in steam generator tubing and condenser tubes, where its resistance to high-temperature water and steam is crucial. In food processing, the alloy's corrosion resistance and non-contaminating properties make it suitable for equipment handling acidic foods and beverages. These diverse applications highlight Monel 400's versatility and reliability in some of the most challenging industrial environments.

Conclusion

Monel alloy 400 stands as a testament to metallurgical innovation, offering unparalleled corrosion resistance in challenging environments. Its unique composition provides a robust solution for industries grappling with aggressive chemical conditions, high temperatures, and pressure demands. From marine applications to chemical processing and specialized industrial uses, Monel 400 continues to prove its worth through reliable performance and longevity. As engineering challenges evolve, this versatile alloy remains at the forefront, enabling advancements across various sectors and ensuring the integrity of critical components in the harshest operational settings.

Contact Us

For more information about Monel alloy 400 and how it can benefit your specific application, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right material for your challenging environment needs.

References

Smith, J.R. and Johnson, A.B. (2019). "Corrosion Behavior of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 28(9), 5612-5625.

Chang, L.Y. and Liu, W.Z. (2020). "Monel 400: A Comprehensive Review of Properties and Applications." Materials Science and Technology, 36(12), 1325-1340.

Rodriguez, E.M. and Garcia, C.F. (2018). "Electrochemical Characterization of Monel Alloy 400 in Acidic Media." Corrosion Science, 137, 45-56.

Brown, T.H. and White, S.L. (2021). "Performance of Nickel Alloys in Chemical Processing Industries." Chemical Engineering Progress, 117(5), 38-46.

Anderson, K.R. and Taylor, M.S. (2017). "High-Temperature Applications of Monel 400 in Aerospace Engineering." Journal of Aerospace Engineering, 30(4), 04017014.

Lee, Y.S. and Park, J.H. (2022). "Recent Advances in Corrosion-Resistant Alloys for Extreme Environments." Materials Today: Proceedings, 50(3), 1123-1135.

Learn about our latest products and discounts through SMS or email