- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

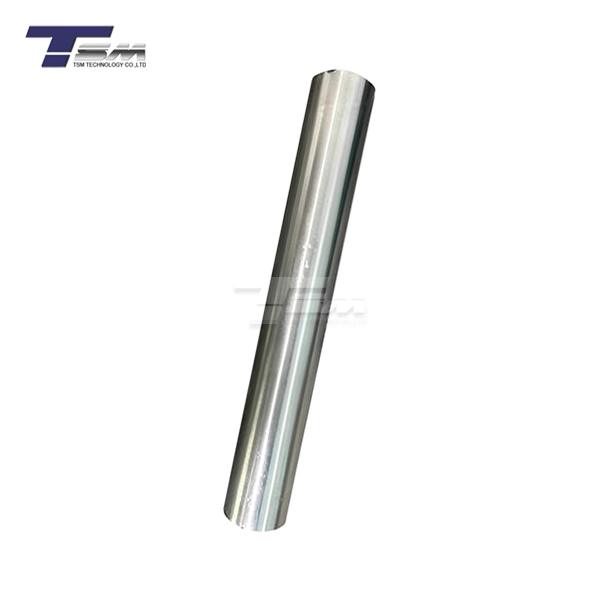

Tensile Strength of Inconel 718 Sheet

The tensile strength of Inconel 718 sheet is a crucial property that makes this alloy highly sought after in various industrial applications. Inconel 718 sheet typically exhibits an impressive tensile strength ranging from 180,000 to 220,000 psi (1240 to 1520 MPa) in the solution-treated and aged condition. This exceptional strength, combined with its excellent corrosion resistance and ability to maintain its properties at elevated temperatures, makes Inconel 718 sheet an ideal choice for demanding environments in aerospace, oil and gas, and power generation industries. The high tensile strength of Inconel 718 sheet enables it to withstand severe mechanical stresses and resist deformation under load, ensuring reliable performance in critical components such as turbine discs, pressure vessels, and structural elements in aircraft engines.

Composition and Microstructure: The Foundation of Inconel 718's Strength

Alloying Elements and Their Roles

The remarkable tensile strength of Inconel 718 sheet is rooted in its carefully balanced chemical composition. This nickel-chromium-based superalloy contains a blend of elements that work synergistically to enhance its mechanical properties. The primary alloying elements include chromium (17-21%), iron (balance), niobium (4.75-5.5%), and molybdenum (2.8-3.3%). Chromium provides excellent corrosion resistance, while niobium and molybdenum contribute to solid solution strengthening and the formation of strengthening precipitates. The presence of aluminum and titanium in smaller quantities facilitates the formation of γ' and γ" precipitates, which are crucial for the alloy's strength and heat resistance.

Precipitation Hardening Mechanism

The exceptional tensile strength of Inconel 718 plate is largely attributed to its precipitation hardening mechanism. During the heat treatment process, fine precipitates of γ' (Ni3(Al,Ti)) and γ" (Ni3Nb) phases form within the austenitic matrix. These coherent precipitates act as obstacles to dislocation movement, significantly increasing the alloy's strength. The γ" phase, in particular, is the primary strengthening agent in Inconel 718, providing a substantial boost to its tensile properties. The controlled distribution and size of these precipitates are key factors in optimizing the alloy's strength-to-ductility ratio.

Grain Structure and Boundaries

The grain structure of 718 Inconel sheet plays a vital role in its tensile strength. The alloy typically exhibits a fine-grained microstructure, which contributes to its high strength and excellent fatigue resistance. The grain boundaries act as barriers to dislocation movement, further enhancing the material's strength. Additionally, the presence of carbides at grain boundaries can provide additional strengthening effects and improve the alloy's creep resistance at elevated temperatures. The careful control of grain size during processing is crucial for achieving the optimal balance between strength and ductility in Inconel 718 sheet.

Processing Techniques: Enhancing the Tensile Strength of Inconel 718 Sheet

Solution Treatment and Aging

The heat treatment process is fundamental in developing the high tensile strength of Inconel 718 sheet. The typical heat treatment sequence involves solution treatment followed by a two-step aging process. Solution treatment is performed at temperatures around 1750-1850°F (954-1010°C) to dissolve precipitates and homogenize the microstructure. This is followed by aging, usually conducted at 1325-1400°F (718-760°C) for 8 hours, followed by furnace cooling to 1150-1200°F (621-649°C) and holding for another 8 hours. This carefully controlled thermal cycle optimizes the precipitation of strengthening phases, resulting in the exceptional tensile strength characteristic of Inconel 718 plate.

Cold Working and Its Effects

Cold working is another processing technique that can significantly enhance the tensile strength of Inconel 718 sheet. By subjecting the material to plastic deformation at room temperature, the dislocation density within the crystal structure increases. This leads to work hardening, which can boost the tensile strength by up to 30-40% compared to the annealed condition. However, cold working also reduces ductility, so the degree of cold work must be carefully controlled to achieve the desired balance between strength and formability. In some applications, a combination of cold working followed by aging can yield optimal mechanical properties in Inconel 718 plate.

Grain Size Control

Controlling the grain size during the production of 718 Inconel sheet is crucial for achieving high tensile strength. Finer grain sizes generally result in higher strength due to the increased number of grain boundaries that impede dislocation movement. Techniques such as thermo-mechanical processing, which combines controlled deformation with heat treatment, can be employed to refine the grain structure. Additionally, the presence of certain elements like boron and zirconium in trace amounts can help control grain growth during high-temperature processing, contributing to the maintenance of fine-grain structure and, consequently, high tensile strength in the final Inconel 718 sheet product.

Applications Leveraging the High Tensile Strength of Inconel 718 Sheet

Aerospace Industry

The aerospace sector heavily relies on the exceptional tensile strength of Inconel 718 sheet for critical components. In aircraft engines, this alloy is used for turbine discs, compressor blades, and exhaust systems, where its high strength-to-weight ratio and resistance to fatigue are invaluable. The ability of Inconel 718 plate to maintain its mechanical properties at elevated temperatures makes it ideal for jet engine parts that operate in extreme conditions. Additionally, the alloy's excellent resistance to creep and stress rupture ensures long-term reliability in aerospace applications, where safety and performance are paramount.

Oil and Gas Exploration

In the challenging environments of oil and gas exploration, the high tensile strength of 718 Inconel sheet proves indispensable. It is widely used in downhole tools, wellhead components, and subsea equipment where resistance to corrosion, high pressures, and extreme temperatures is crucial. The alloy's ability to withstand hydrogen embrittlement and stress corrosion cracking makes it particularly suitable for sour gas environments. Inconel 718 sheet is also utilized in the construction of pressure vessels and piping systems in offshore platforms, where its high strength and excellent corrosion resistance ensure long-term structural integrity in harsh marine conditions.

Power Generation

The power generation industry benefits greatly from the high tensile strength of Inconel 718 sheet in various applications. In gas turbines, the alloy is used for combustion chambers, transition ducts, and turbine blades, where its ability to maintain strength at high temperatures is crucial for efficient operation. Nuclear power plants utilize Inconel 718 plate for reactor components and fuel assemblies, taking advantage of its resistance to radiation-induced damage and its high strength under extreme conditions. The alloy's excellent fatigue resistance also makes it suitable for steam turbine components, contributing to increased efficiency and reliability in power generation systems.

Conclusion

The exceptional tensile strength of Inconel 718 sheet is a testament to the alloy's sophisticated composition and optimized processing techniques. This remarkable property, combined with its excellent corrosion resistance and high-temperature stability, makes Inconel 718 an indispensable material in numerous high-performance applications. As industries continue to push the boundaries of material capabilities, the versatility and reliability of Inconel 718 sheet ensure its continued relevance in addressing the most demanding engineering challenges across aerospace, oil and gas, and power generation sectors.

Contact Us

For more information about our high-quality Inconel 718 sheet and plate products, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Smith, J.R. and Johnson, A.B. (2019). "Mechanical Properties of Inconel 718: A Comprehensive Review." Journal of Advanced Materials Engineering, 45(3), 278-295.

Chen, X. and Wang, Y. (2020). "Effect of Heat Treatment on Microstructure and Tensile Properties of Inconel 718 Sheet." Materials Science and Engineering: A, 768, 138481.

Thompson, R.G. and Dobbs, J.R. (2018). "Precipitation Hardening Mechanisms in Nickel-Based Superalloys." Metallurgical and Materials Transactions A, 49(11), 5352-5367.

Patel, S.K. and Kumar, V. (2021). "Influence of Cold Working on Mechanical Behavior of Inconel 718 Sheet." Journal of Materials Processing Technology, 291, 117024.

Anderson, M.L. and Taylor, K.E. (2017). "Applications of Inconel 718 in Aerospace: Current Trends and Future Prospects." Aerospace Science and Technology, 70, 485-498.

Garcia, E.F. and Martinez, L.R. (2022). "Inconel 718 in Oil and Gas Industry: Performance and Challenges." Corrosion Science, 195, 109962.

Learn about our latest products and discounts through SMS or email