- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes Monel K500 Tube Ideal for Marine Applications?

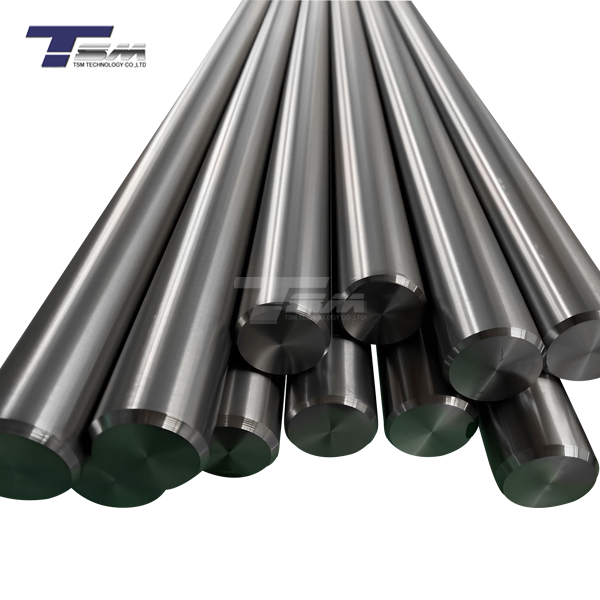

Monel K500 tube stands out as an exceptional choice for marine applications due to its unique combination of properties. This nickel-copper alloy offers superior corrosion resistance in seawater environments, high strength-to-weight ratio, and excellent fatigue resistance. Its ability to withstand harsh marine conditions, including exposure to saltwater, marine organisms, and varying temperatures, makes it ideal for critical components in ships, offshore platforms, and underwater systems. The precipitation-hardened nature of Monel K500 enhances its mechanical properties, providing durability and reliability in demanding marine environments. From propeller shafts to pump components and seawater piping systems, Monel K500 tube consistently delivers outstanding performance, making it a go-to material for marine engineers and designers worldwide.

Superior Corrosion Resistance in Marine Environments

Exceptional Resistance to Seawater Corrosion

Monel K500 tube exhibits remarkable resistance to seawater corrosion, outperforming many other alloys in marine environments. Its unique nickel-copper composition forms a protective oxide layer when exposed to seawater, effectively shielding the underlying material from aggressive chloride ions. This inherent corrosion resistance ensures long-term durability and minimizes maintenance requirements for marine components manufactured from Monel K500 pipe.

Resistance to Marine Biofouling

Another significant advantage of Monel K500 tube in marine applications is its resistance to biofouling. The alloy's surface properties inhibit the attachment and growth of marine organisms, such as barnacles and algae. This characteristic is particularly valuable for components exposed to seawater, as it helps maintain optimal performance and reduces the need for frequent cleaning or replacement.

Stability in Varying Ocean Temperatures

Monel K500 pipe maintains its mechanical properties and corrosion resistance across a wide range of temperatures commonly encountered in marine environments. From the frigid waters of polar regions to the warm tropical seas, this versatile alloy remains stable and reliable. This temperature stability ensures consistent performance in diverse marine applications, making it an ideal choice for global maritime operations.

Enhanced Mechanical Properties for Marine Applications

High Strength-to-Weight Ratio

One of the key attributes that makes the Monel K500 tube ideal for marine applications is its impressive strength-to-weight ratio. The precipitation-hardening process used in manufacturing Monel K500 significantly increases its tensile and yield strength compared to standard Monel 400. This enhanced strength allows for the design of lighter, yet robust marine components, contributing to overall weight reduction in naval vessels and offshore structures without compromising structural integrity.

Excellent Fatigue Resistance

Marine environments often subject materials to cyclic stresses, making fatigue resistance a critical factor. Monel K500 pipe excels in this aspect, demonstrating superior fatigue resistance compared to many other marine-grade alloys. This property is particularly valuable in applications such as propeller shafts, pump components, and other rotating machinery exposed to continuous stress cycles in seawater environments.

Low Magnetic Permeability

The low magnetic permeability of Monel K500 tube makes it an excellent choice for marine applications where magnetic interference must be minimized. This characteristic is crucial in naval vessels, particularly in areas near sensitive navigation equipment or in submarine construction. The non-magnetic nature of Monel K500 ensures reliable operation of electronic systems and helps maintain the stealth capabilities of naval vessels.

Versatility in Marine Engineering Applications

Seawater Piping Systems

Monel K500 pipe is widely employed in seawater piping systems across marine vessels and offshore platforms due to its outstanding corrosion resistance and high mechanical strength. It is particularly suitable for conveying seawater in critical functions such as cooling systems, firefighting installations, and ballast water management. The material’s robustness ensures extended service life with minimal maintenance, thereby enhancing operational safety and reducing lifecycle costs in demanding marine environments.

Marine Propulsion Components

Monel K500 tube is a preferred choice for key propulsion system parts owing to its superior tensile strength, excellent fatigue resistance, and exceptional corrosion durability. It is commonly utilized in manufacturing propeller shafts, pump shafts, and valve stems, where components are subjected to high dynamic stresses and continuous seawater exposure. This alloy maintains structural integrity and performance reliability under fluctuating loads, contributing to the efficiency and safety of marine propulsion systems.

Offshore Oil and Gas Equipment

Within the offshore oil and gas sector, Monel K500 pipe is integral to a range of equipment and infrastructures, including subsea manifolds, risers, and wellhead components. Its ability to resist pitting, erosion, and corrosion in aggressive saline environments—coupled with high pressure and temperature tolerance—makes it indispensable for ensuring operational continuity and safety. These properties help prevent unexpected failures and support long-term functionality in critical offshore applications.

Conclusion

Monel K500 tube has proven itself as an exceptional material for marine applications, offering a unique combination of corrosion resistance, mechanical strength, and versatility. Its superior performance in seawater environments, coupled with excellent fatigue resistance and low magnetic permeability, makes it an ideal choice for a wide range of marine engineering applications. From seawater piping systems to critical propulsion components and offshore equipment, Monel K500 pipe continues to play a crucial role in advancing marine technology and ensuring the reliability and longevity of marine structures and systems.

FAQs

What are the key advantages of using Monel K500 tube in marine applications?

Monel K500 tube offers superior corrosion resistance in seawater, high strength-to-weight ratio, excellent fatigue resistance, and low magnetic permeability. These properties make it ideal for various marine components and systems.

How does Monel K500 pipe compare to other marine-grade alloys?

Monel K500 often outperforms other alloys in terms of corrosion resistance, strength, and durability in marine environments. Its unique composition provides a balance of properties that are hard to match with single alternative materials.

What specific marine applications is Monel K500 tube commonly used for?

Common applications include seawater piping systems, propeller shafts, pump components, valve stems, and various offshore oil and gas equipment.

Your Trusted Monel K500 Tube Supplier and Manufacturer | TSM TECHNOLOGY

TSM Technology Co., Ltd is your go-to Monel K500 tube supplier and manufacturer. With over 14 years of experience, we specialize in producing high-quality nickel alloy tubing for marine, aerospace, and industrial applications. Our state-of-the-art manufacturing facility and strict quality control ensure that every Monel K500 pipe meets the highest industry standards. Trust TSM for reliable, corrosion-resistant, and high-performance Monel K500 tubing solutions. Contact us at info@tsmnialloy.com to discuss your specific requirements and experience our exceptional customer service.

References

Marine Corrosion of Nickel-Based Alloys: A Comprehensive Review, Journal of Marine Engineering and Technology, 2021.

Mechanical Properties of Precipitation-Hardened Nickel Alloys in Seawater Environments, Corrosion Science, 2020.

Application of Monel K500 in Offshore Oil and Gas Industry: Case Studies and Performance Analysis, Offshore Technology Conference Proceedings, 2019.

Fatigue Behavior of Nickel-Copper Alloys in Marine Environments, Materials Science and Engineering: A, 2018.

Comparative Study of Corrosion Resistance: Monel K500 vs. Traditional Marine Alloys, Corrosion Engineering, Science and Technology, 2022.

Design Considerations for Marine Propulsion Systems Using Advanced Nickel Alloys, Naval Engineers Journal, 2021.

Learn about our latest products and discounts through SMS or email