Understanding Nickel Alloy Plate Properties and Welding Implications

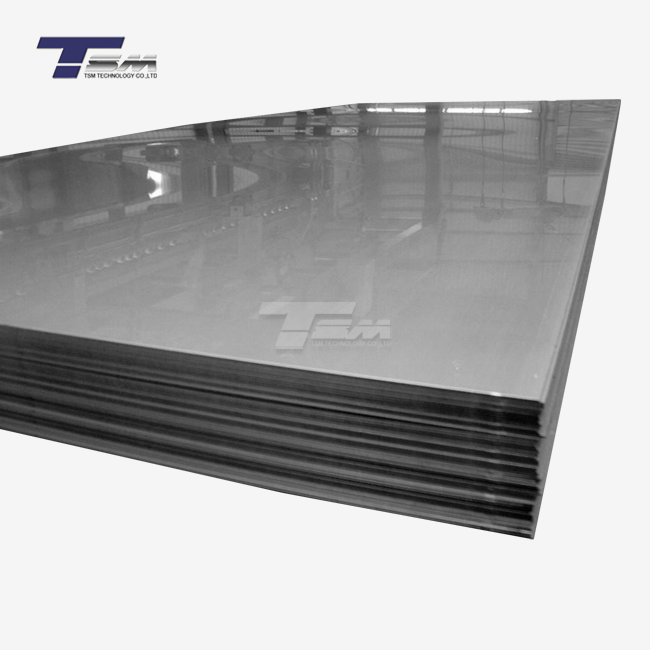

Composition and Microstructure of Nickel Alloy Plates

Nickel alloy plates are engineered materials composed primarily of nickel with varying amounts of other elements such as chromium, molybdenum, and tungsten. These alloys exhibit a face-centered cubic (FCC) crystal structure, which contributes to their excellent ductility and toughness. The precise composition of nickel alloy plates can significantly impact their weldability. For instance, alloys with higher chromium content may form chromium carbides during welding, potentially leading to sensitization and reduced corrosion resistance in the heat-affected zone (HAZ).

The microstructure of nickel alloy plates typically consists of a solid solution matrix with dispersed strengthening precipitates. These precipitates, such as gamma prime (γ') in superalloys, play a crucial role in maintaining the alloy's high-temperature strength. However, during welding, these precipitates can dissolve or coarsen, affecting the mechanical properties of the welded joint. Understanding the specific microstructural features of the nickel alloy plate being welded is essential for selecting appropriate welding parameters and filler materials.

Thermal and Mechanical Behavior During Welding

Nickel alloy plates exhibit unique thermal behavior during welding processes. Their relatively low thermal conductivity compared to steels results in a more concentrated heat-affected zone. This characteristic can lead to steep thermal gradients and rapid cooling rates, potentially causing thermal stresses and distortion in the welded component. Additionally, the high coefficient of thermal expansion of nickel alloys can exacerbate these issues, necessitating careful control of heat input and interpass temperatures during multi-pass welds.

The mechanical behavior of nickel alloy plates under welding conditions is characterized by their resistance to deformation at elevated temperatures. This property, while beneficial for high-temperature applications, can pose challenges during welding. The material's high yield strength at welding temperatures can result in residual stresses being locked into the weldment upon cooling. These stresses may lead to distortion or, in severe cases, cracking if not properly managed through appropriate pre-heating, post-weld heat treatment, or stress-relieving techniques.

Corrosion Resistance Considerations in Welded Joints

One of the primary reasons for selecting nickel alloy plates is their exceptional corrosion resistance in aggressive environments. However, the welding process can potentially compromise this critical property if not executed correctly. The heat input during welding can cause localized changes in the alloy's microstructure, particularly in the heat-affected zone. These changes may include the formation of chromium-depleted regions near grain boundaries, a phenomenon known as sensitization, which can render the material susceptible to intergranular corrosion.

To maintain the corrosion resistance of welded nickel alloy plates, it's crucial to employ welding techniques that minimize heat input and control cooling rates. The use of low-carbon or stabilized grades of nickel alloys can help mitigate sensitization. Additionally, post-weld heat treatments may be necessary to restore the corrosion-resistant microstructure. Proper selection of filler metals that match or exceed the corrosion resistance of the base metal is also essential to ensure the long-term integrity of the welded joint in corrosive environments.

Common Welding Challenges with Nickel Alloy Plates

Hot Cracking and Solidification Issues

Hot cracking, also known as solidification cracking, is a significant challenge when welding nickel alloy plates. This phenomenon occurs during the final stages of weld pool solidification, where low-melting-point constituents form along grain boundaries, leading to weakness and potential crack formation. The susceptibility to hot cracking is influenced by factors such as the alloy composition, welding parameters, and joint design. Nickel alloys with high amounts of elements like sulfur and phosphorus are particularly prone to this issue.

To mitigate hot cracking in nickel alloy plate welds, several strategies can be employed. Reducing the heat input and controlling the cooling rate can help minimize the formation of low-melting-point phases. Optimizing the joint design to reduce stress concentrations and using filler metals with compositions that promote favorable solidification characteristics can also be effective. In some cases, the addition of elements like niobium or tantalum to the weld metal can help tie up detrimental impurities and reduce the risk of cracking.

Porosity and Gas Entrapment

Porosity is another common defect encountered when welding nickel alloy plates. It manifests as small, spherical voids within the weld metal, caused by gas entrapment during solidification. The sources of this gas can be diverse, including contamination on the plate surface, inadequate shielding gas coverage, or the release of dissolved gases from the molten weld pool. Nickel alloys are particularly sensitive to porosity due to their high solubility for gases like hydrogen and nitrogen at elevated temperatures.

Addressing porosity in nickel alloy plate welds requires a multi-faceted approach. Thorough cleaning of the base metal and filler wire to remove contaminants is crucial. Proper storage and handling of filler materials to prevent moisture absorption is also essential. Optimizing welding parameters, such as arc length and travel speed, can help reduce the likelihood of gas entrapment. In some cases, using a pulsed welding technique or implementing specialized shielding gas mixtures can further minimize porosity formation.

Loss of Alloying Elements and Compositional Changes

The high temperatures involved in welding nickel alloy plates can lead to the loss of volatile alloying elements, potentially altering the composition and properties of the weld metal. Elements like chromium, which are critical for corrosion resistance, can be preferentially oxidized and lost from the weld pool. This loss can result in a weld composition that differs significantly from the base metal, potentially compromising the performance of the welded joint.

Mitigating the loss of alloying elements requires careful control of the welding process. Using lower heat inputs and shorter arc lengths can help reduce element volatilization. The selection of filler metals with slightly higher concentrations of critical elements can compensate for expected losses. In some cases, welding in a controlled atmosphere or under a flux cover can provide additional protection against element loss. Post-weld heat treatments may also be employed to homogenize the composition and restore desired properties to the weld zone.

Advanced Welding Techniques for Nickel Alloy Plates

Gas Tungsten Arc Welding (GTAW) Optimization

Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is a preferred method for welding nickel alloy plates due to its precise control and high-quality results. To optimize GTAW for nickel alloys, several factors must be considered. The choice of tungsten electrode is crucial, with 2% thoriated or lanthanated electrodes often providing the best arc stability and longevity. Argon is typically used as the shielding gas, but for thicker plates or high-alloy materials, a mixture of argon and helium can enhance penetration and heat input control.

Pulsed GTAW techniques can be particularly effective for nickel alloy plates. By alternating between high and low current levels, pulsed GTAW allows for better control of the weld pool, reduced heat input, and improved grain structure in the weld metal. This technique is especially beneficial for controlling distortion in thin nickel alloy plates and managing heat-sensitive alloys. Implementing automated GTAW systems with precise parameter control can further enhance weld quality and consistency, particularly for complex or repetitive welding tasks on nickel alloy components.

Electron Beam and Laser Welding Applications

Electron Beam Welding (EBW) and Laser Beam Welding (LBW) represent advanced welding technologies that offer unique advantages for nickel alloy plates. These high-energy density processes can produce deep, narrow welds with minimal heat input, reducing the risk of distortion and microstructural changes in the heat-affected zone. EBW, performed in a vacuum environment, is particularly effective for thick nickel alloy plates, as it can achieve full penetration welds in a single pass, even for sections exceeding 100mm in thickness.

Laser welding, especially with the advent of high-power fiber and disk lasers, has become increasingly popular for nickel alloy plate fabrication. The precise control of energy delivery allows for narrow weld beads and minimal heat-affected zones, making it ideal for thin-section welding and intricate components. Hybrid laser-arc welding techniques, combining the benefits of laser welding with those of traditional arc processes, can offer improved gap bridging capabilities and increased productivity for nickel alloy plate welding in industrial applications.

Friction Stir Welding for Solid-State Joining

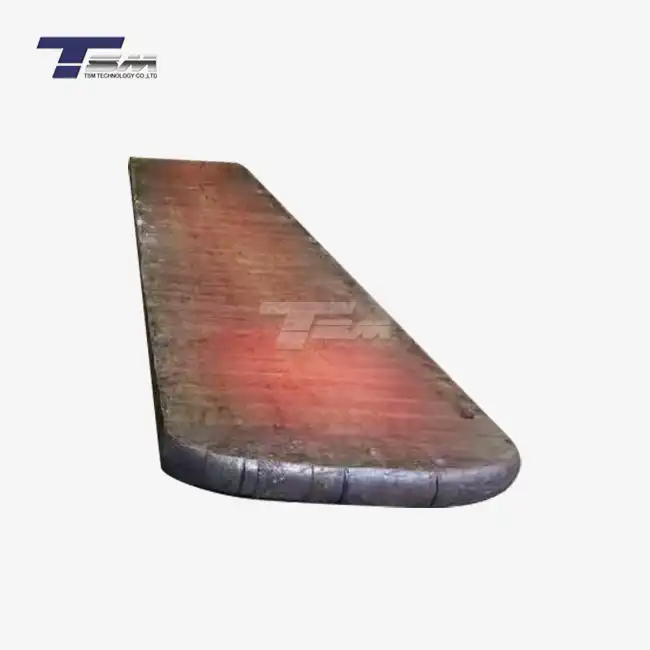

Friction Stir Welding (FSW) is an innovative solid-state joining process that has shown promise for welding nickel alloy plates, particularly in applications where maintaining the base metal's microstructure is critical. In FSW, a rotating tool is plunged into the joint line, generating heat through friction and plastic deformation. The material is then mechanically mixed, creating a bond without melting. This process eliminates many of the challenges associated with the fusion welding of nickel alloys, such as hot cracking and porosity.

For nickel alloy plates, FSW offers several advantages. The lower peak temperatures involved in the process reduce the risk of grain growth and precipitate coarsening, helping to maintain the alloy's mechanical properties. The absence of a fusion zone also minimizes issues related to segregation and loss of alloying elements. However, implementing FSW for nickel alloys requires specialized tooling capable of withstanding the high temperatures and forces involved. Ongoing research is focused on developing advanced tool materials and optimizing process parameters to expand the applicability of FSW to a broader range of nickel alloy compositions and thicknesses.

Conclusion

Welding nickel alloy plates demands a deep understanding of material properties and advanced techniques to overcome inherent challenges. By carefully considering factors such as alloy composition, thermal behavior, and corrosion resistance, manufacturers can select appropriate welding methods and parameters. Advanced techniques like optimized GTAW, electron beam welding, and friction stir welding offer innovative solutions to traditional problems. As technology progresses, new opportunities arise for improving weld quality and efficiency in nickel alloy fabrication. Successful welding of these high-performance materials enables their use in critical applications across aerospace, chemical processing, and energy sectors, driving technological advancements in extreme environments.

FAQs

What are the main challenges in welding nickel alloy plates?

The primary challenges include hot cracking, porosity, loss of alloying elements, and maintaining corrosion resistance in the welded joint.

Which welding technique is most suitable for thin nickel alloy plates?

Gas Tungsten Arc Welding (GTAW) with pulsed current is often preferred for thin nickel alloy plates due to its precise heat control and minimal distortion.

How can the risk of hot cracking be reduced when welding nickel alloy plates?

Hot cracking can be mitigated by controlling heat input, optimizing joint design, and using filler metals with compositions that promote favorable solidification characteristics.

Expert Nickel Alloy Plate Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality nickel alloy plates and expert welding solutions. Our state-of-the-art manufacturing facilities and skilled technicians ensure precise fabrication of nickel alloy components. Whether you need Monel, Inconel, or Hastelloy plates, our extensive inventory and global supply chain guarantee timely delivery. For personalized assistance with your nickel alloy plate requirements, contact our team at info@tsmnialloy.com.

References

DuPont, J.N., Lippold, J.C., & Kiser, S.D. (2019). Welding Metallurgy and Weldability of Nickel-Base Alloys. John Wiley & Sons.

Kou, S. (2020). Welding Metallurgy. John Wiley & Sons.

Lippold, J.C. (2015). Welding Metallurgy and Weldability. John Wiley & Sons.

ASM International. (2018). ASM Handbook, Volume 6A: Welding Fundamentals and Processes. ASM International.

Mishra, R.S., & Ma, Z.Y. (2005). Friction stir welding and processing. Materials Science and Engineering: R: Reports, 50(1-2), 1-78.

Shrestha, S., & Bhat, A. (2018). Challenges in welding of nickel-based superalloys. Welding Journal, 97(3), 72-77.