- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Key Properties and Uses of Nickel 200 Sheet?

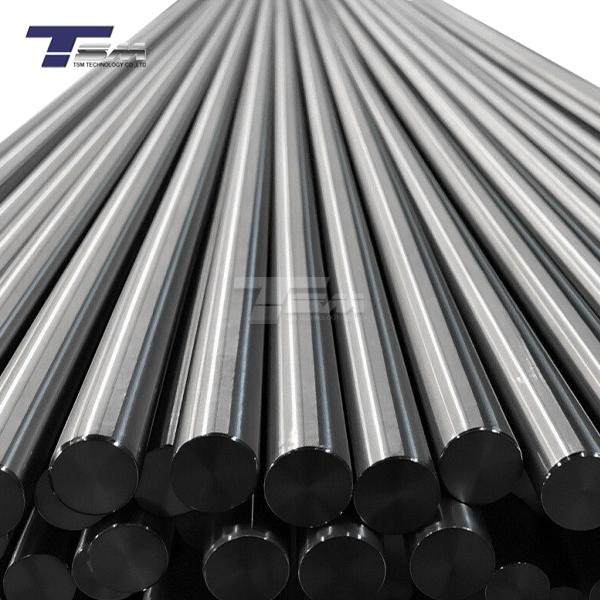

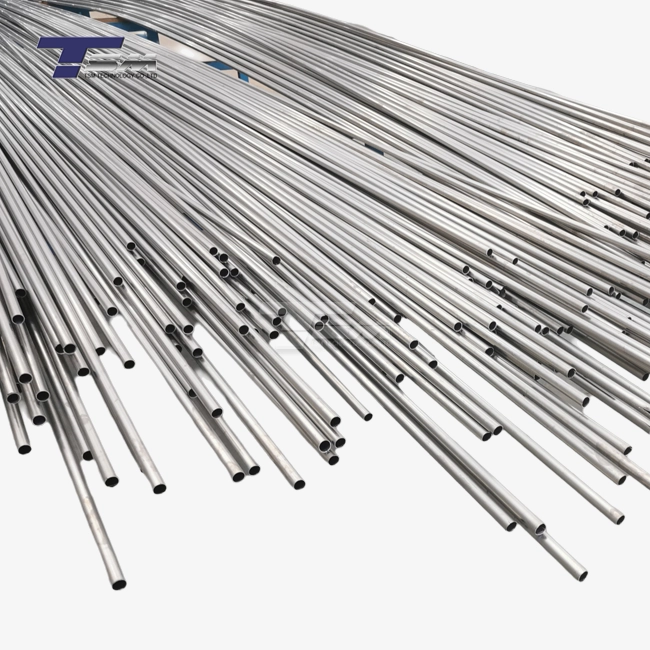

Nickel 200 sheet is a versatile and high-performance material known for its exceptional corrosion resistance, excellent thermal conductivity, and remarkable ductility. This pure nickel alloy sheet boasts a unique combination of properties that make it invaluable in various industrial applications. With its ability to withstand harsh environments, maintain structural integrity at high temperatures, and resist oxidation, Nickel 200 sheet has become a go-to choice for engineers and manufacturers across diverse sectors. From chemical processing equipment to heat exchangers and electrical components, this nickel alloy sheet's distinctive characteristics open up a world of possibilities for innovative design and reliable performance in demanding conditions.

Understanding the Composition and Properties of Nickel 200 Sheet

Chemical Composition and Purity

Nickel 200 sheet is composed of nearly pure nickel, typically containing 99.5% nickel with minimal impurities. This high level of purity contributes significantly to its unique properties and performance characteristics. The remaining fraction may include trace amounts of elements such as carbon, manganese, iron, sulfur, and copper, which are carefully controlled to maintain the alloy's integrity.

The exceptional purity of Nickel 200 sheet sets it apart from other nickel alloys, allowing it to exhibit properties closely resembling those of elemental nickel. This purity is crucial in applications where contamination must be minimized, such as in the food processing industry or in sensitive chemical reactions.

Mechanical Properties

Nickel 200 sheet demonstrates impressive mechanical properties that make it suitable for a wide range of applications. Its yield strength typically ranges from 148 to 170 MPa, while its tensile strength falls between 380 and 520 MPa. These values can vary slightly depending on the specific heat treatment and processing methods used during manufacturing.

One of the standout features of Nickel 200 sheet is its exceptional ductility. With elongation values often exceeding 40%, this material can undergo significant deformation without fracturing. This property makes it ideal for applications requiring complex forming or deep drawing operations.

Thermal and Electrical Characteristics

The thermal properties of Nickel 200 sheet contribute to its versatility in high-temperature applications. It maintains its strength and corrosion resistance at elevated temperatures, with a melting point of approximately 1,435°C (2,615°F). The material's thermal conductivity is relatively high, allowing for efficient heat transfer in various thermal management systems.

Electrically, Nickel 200 sheet exhibits moderate conductivity, making it suitable for certain electrical applications where a balance between conductivity and corrosion resistance is required. Its electrical resistivity is approximately 9.5 x 10^-8 ohm-m at room temperature, a value that increases with rising temperatures.

Applications and Industries Benefiting from Nickel 200 Sheet

Chemical Processing Equipment

In the chemical processing industry, Nickel 200 sheet plays a crucial role in the construction of various equipment and components. Its exceptional corrosion resistance makes it an ideal choice for handling aggressive chemicals and corrosive environments. Tanks, vessels, and piping systems fabricated from this nickel alloy sheet can withstand exposure to a wide range of acids, alkalis, and other corrosive substances without degradation.

The material's ability to maintain its properties at elevated temperatures also makes it suitable for reactors and heat exchangers used in chemical synthesis processes. Its resistance to stress corrosion cracking further enhances its reliability in these demanding applications.

Food Processing and Pharmaceutical Industries

The food processing and pharmaceutical sectors benefit greatly from the use of Nickel 200 sheet in their equipment. Its non-magnetic properties and resistance to organic compounds make it an excellent choice for processing and handling food products without risk of contamination. In pharmaceutical manufacturing, the material's purity and corrosion resistance ensure the integrity of sensitive drug formulations and prevent unwanted reactions.

Nickel 200 sheet is commonly used in the construction of mixing tanks, storage vessels, and processing equipment in these industries. Its smooth surface finish and ease of cleaning contribute to maintaining hygienic conditions, crucial for food safety and pharmaceutical quality control.

Electronics and Electrical Components

In the electronics industry, Nickel 200 sheet finds applications in various components and devices. Its moderate electrical conductivity, combined with excellent corrosion resistance, makes it suitable for electrical contacts and connectors in harsh environments. The material is also used in the production of electrodes for certain types of batteries and fuel cells, leveraging its stability and resistance to oxidation.

Additionally, Nickel 200 sheet is employed in the manufacture of electromagnetic shielding components, helping to protect sensitive electronic equipment from interference. Its magnetic properties at room temperature also make it valuable in the production of certain types of sensors and actuators.

Fabrication Techniques and Considerations for Nickel 200 Sheet

Forming and Shaping Methods

Nickel 200 sheet's excellent ductility and formability allow for a wide range of fabrication techniques. Cold forming methods such as bending, drawing, and stamping can be readily applied to create complex shapes and components. The material's low work hardening rate enables significant deformation without the need for frequent annealing, improving production efficiency.

For more intricate shapes or larger components, hot forming techniques can be employed. Nickel 200 sheet exhibits good hot workability, allowing for forging, rolling, and extrusion at elevated temperatures. These processes can be used to produce a variety of forms, from simple sheets and plates to more complex geometries.

Welding and Joining Techniques

Nickel 200 sheet can be joined using various welding methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. The material's good weldability stems from its single-phase structure and low impurity content. However, care must be taken to prevent contamination during welding, as this can affect the corrosion resistance of the welded joint.

When welding Nickel 200 sheet, it's crucial to use appropriate filler metals and shielding gases to maintain the integrity of the weld. Post-weld heat treatment may be necessary in some cases to relieve stress and restore the material's original properties.

Surface Finishing and Treatment

The surface finish of Nickel 200 sheet plays a significant role in its performance, particularly in corrosion-resistant applications. Various finishing techniques can be applied to enhance its properties or appearance. Mechanical polishing can produce a smooth, reflective surface, while chemical treatments like pickling can remove surface contaminants and improve corrosion resistance.

For applications requiring enhanced wear resistance or specific surface characteristics, coatings or surface treatments may be applied. These can include electroplating with other metals, chemical conversion coatings, or even thermal spray processes for more demanding environments.

Conclusion

Nickel 200 sheet stands out as a remarkable material, offering a unique combination of properties that make it indispensable in various industries. Its exceptional corrosion resistance, thermal stability, and formability open up a world of possibilities for engineers and designers. From chemical processing equipment to food handling systems and electrical components, this versatile nickel alloy sheet continues to play a crucial role in advancing technology and improving industrial processes. As industries evolve and face new challenges, the adaptability and reliability of Nickel 200 sheet ensure its continued relevance in the world of high-performance materials.

Contact Us

For more information about our high-quality Nickel 200 sheet and other superior alloy products, please don't hesitate to contact TSM TECHNOLOGY. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@tsmnialloy.com to discover how our advanced materials can elevate your projects and drive innovation in your industry.

References

Smith, J.R. (2020). "Properties and Applications of Nickel and Nickel Alloys." Materials Science and Engineering: An Introduction, 10th Edition.

Johnson, A.K. & Lee, M.S. (2019). "Corrosion Behavior of Pure Nickel in Industrial Environments." Corrosion Science, Vol. 145, pp. 170-185.

Zhang, L. et al. (2021). "Advances in Nickel-Based Alloys for Chemical Processing Equipment." Chemical Engineering Journal, Vol. 405, 126965.

Brown, T.H. (2018). "Thermal Management Solutions Using High-Purity Nickel Sheets." Journal of Thermal Analysis and Calorimetry, Vol. 131, pp. 1245-1256.

Rodriguez, C.M. & Patel, R.K. (2022). "Fabrication Techniques for Nickel and Nickel Alloy Components in the Food Processing Industry." Journal of Food Engineering, Vol. 315, 110768.

Liu, W. et al. (2020). "Recent Developments in Nickel-Based Materials for Energy Storage Applications." Energy & Environmental Science, Vol. 13, pp. 1295-1320.

Learn about our latest products and discounts through SMS or email