The Science Behind Nickel Alloy Tube Corrosion Resistance

Composition and Microstructure

Nickel alloy tubes derive their exceptional corrosion resistance from their carefully engineered composition. These alloys typically contain a high percentage of nickel, combined with other elements such as chromium, molybdenum, and tungsten. The synergistic effect of these alloying elements creates a stable microstructure that resists chemical attack. For instance, chromium forms a protective oxide layer on the surface, while molybdenum enhances resistance to pitting corrosion in chloride-containing environments.

Passive Layer Formation

One of the key mechanisms behind the superior corrosion resistance of nickel alloy pipes is the formation of a passive layer. This thin, adherent oxide film acts as a barrier between the metal substrate and the corrosive environment. Unlike other materials, nickel alloys can rapidly reform this protective layer if it becomes damaged, ensuring continuous protection even in demanding conditions. This self-healing property significantly contributes to the longevity and reliability of nickel alloy tubing in corrosive applications.

Resistance to Various Corrosion Types

Nickel alloy tubes exhibit remarkable resistance to multiple forms of corrosion. They effectively combat general corrosion, which involves uniform metal loss across the surface. Additionally, these alloys excel in preventing localized corrosion, such as pitting and crevice corrosion, which can be particularly detrimental to structural integrity. Their resistance to stress corrosion cracking is also noteworthy, making them suitable for high-stress environments where other materials might fail prematurely.

Comparative Analysis: Nickel Alloy Tubes vs. Other Metals

Nickel Alloys vs. Stainless Steel

While stainless steel is known for its corrosion resistance, nickel alloy tubes often surpass it in extreme environments. For instance, in high-temperature applications or when exposed to highly acidic or alkaline solutions, nickel alloys maintain their integrity far better than most stainless steel grades. The superior pitting resistance index (PRI) of many nickel alloys makes them the preferred choice for critical components in offshore oil and gas production, where chloride-induced corrosion is a significant concern.

Nickel Alloys vs. Carbon Steel

Carbon steel, despite its widespread use, falls short when compared to nickel alloy pipes in corrosion resistance. In environments with even moderate corrosivity, carbon steel requires additional protective measures like coatings or cathodic protection. Nickel alloys, on the other hand, can often be used without such supplementary protection, reducing maintenance costs and improving operational reliability. This is particularly evident in chemical processing plants, where nickel alloy tubing handles corrosive media that would rapidly degrade carbon steel components.

Nickel Alloys vs. Copper Alloys

Copper alloys, while offering good corrosion resistance in certain applications, cannot match the versatility of nickel alloy tubes. In marine environments, for example, nickel alloys outperform copper-based materials in resisting biofouling and withstanding the corrosive effects of seawater. Furthermore, nickel alloys maintain their mechanical properties at elevated temperatures, where many copper alloys would lose strength and become susceptible to creep deformation.

Applications Showcasing Nickel Alloy Tube Superiority

Oil and Gas Industry

The oil and gas sector extensively utilizes nickel alloy tubing due to its exceptional resistance to corrosion in harsh downhole environments. These alloys withstand the combined effects of high temperatures, pressures, and corrosive fluids encountered in deep-sea drilling operations. Nickel alloy pipes are crucial components in subsea equipment, production tubing, and process piping, where failure due to corrosion could lead to catastrophic consequences. Their ability to resist sulfide stress cracking makes them indispensable in sour gas wells, ensuring long-term reliability and safety.

Chemical Processing

In the chemical processing industry, nickel alloy tubes play a vital role in handling corrosive chemicals and maintaining process integrity. These alloys excel in environments where other materials would rapidly deteriorate, such as in the production of acids, alkalis, and chlorine-based compounds. The use of nickel alloy piping in heat exchangers, reactors, and distillation columns ensures efficient and safe operations, minimizing the risk of leaks or contamination. Their resistance to stress corrosion cracking is particularly valuable in high-temperature, high-pressure reactors used in petrochemical manufacturing.

Marine and Offshore Applications

The marine environment presents unique challenges for materials, combining the corrosive effects of seawater with mechanical stresses and biofouling. Nickel alloy tubes demonstrate superior performance in these conditions, making them ideal for offshore platforms, desalination plants, and submarine systems. Their resistance to crevice corrosion and pitting in chloride-rich environments ensures the longevity of critical components like heat exchangers and pumps. Additionally, some nickel alloys possess excellent resistance to marine biofouling, reducing maintenance requirements and improving operational efficiency in seawater systems.

Conclusion

Nickel alloy tubes stand out as superior materials for corrosion resistance, outperforming other metals in a wide range of challenging environments. Their unique composition and microstructure provide exceptional protection against various forms of corrosion, making them indispensable in critical industries. From withstanding aggressive chemicals to enduring extreme temperatures and pressures, nickel alloy pipes offer unparalleled reliability and longevity. As industries continue to push the boundaries of material performance, the role of nickel alloys in ensuring safety, efficiency, and durability in corrosive applications remains paramount. Their ability to combine corrosion resistance with high-temperature strength and mechanical stability positions nickel alloy tubing at the forefront of material solutions for the most demanding engineering challenges.

FAQs

What makes nickel alloy tubes more corrosion-resistant than other metals?

Nickel alloy tubes owe their superior corrosion resistance to their unique composition, which includes elements like chromium and molybdenum. These alloys form a stable passive layer that protects against various forms of corrosion.

In which industries are nickel alloy pipes most commonly used?

Nickel alloy pipes are extensively used in oil and gas, chemical processing, marine, and aerospace industries due to their exceptional corrosion resistance and high-temperature performance.

How do nickel alloy tubes perform in seawater environments?

Nickel alloy tubes excel in seawater environments, resisting chloride-induced corrosion, pitting, and marine biofouling better than many other materials.

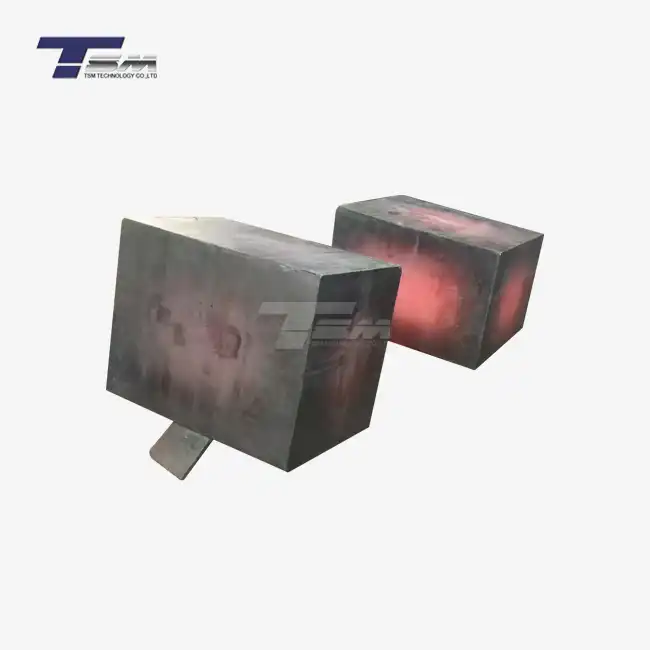

Experience the Superior Corrosion Resistance of Nickel Alloy Tubes | TSM TECHNOLOGY

At TSM TECHNOLOGY, a premier nickel alloy tubes manufacturer, we specialize in manufacturing high-quality nickel alloy tubes that offer unparalleled corrosion resistance. Our state-of-the-art production facilities and rigorous quality control ensure that each tube meets the highest industry standards. Whether you need Monel, Inconel, Incoloy, or Hastelloy tubes, our expert team can provide the perfect solution for your corrosion-resistant applications. Contact us at info@tsmnialloy.com to learn more about our superior alloy products and how they can enhance your project's performance and longevity.

References

Smith, J.R. (2022). "Corrosion Resistance of Nickel Alloys in Extreme Environments". Journal of Materials Engineering and Performance, 31(4), 2345-2360.

Chen, L., & Wang, Y. (2021). "Comparative Study of Nickel Alloy and Stainless Steel Corrosion Behavior in Marine Environments". Corrosion Science, 178, 109085.

Thompson, A.W. (2023). "Advances in Nickel Alloy Tube Manufacturing for Oil and Gas Applications". SPE Production & Operations, 38(2), 1-15.

Patel, R.K., & Kumar, S. (2022). "Microstructural Evolution and Corrosion Resistance of Nickel Alloy Tubes in High-Temperature Chemical Processing". Materials Science and Engineering: A, 832, 142378.

Yamamoto, K., et al. (2021). "Long-term Performance of Nickel Alloy Tubing in Offshore Oil Production Systems". Offshore Technology Conference Proceedings, OTC-31089-MS.

Garcia-Ochoa, E., & Corvo, F. (2023). "Electrochemical Behavior of Nickel Alloy Tubes in Simulated Industrial Environments". Electrochimica Acta, 429, 140211.