Understanding Nickel Alloys: Composition and Properties

Chemical Composition of Nickel Alloys

Nickel alloys are complex materials engineered to possess specific properties by carefully combining nickel with various alloying elements. The composition of these alloys can vary significantly, depending on the desired characteristics and intended applications. Some common alloying elements include chromium, molybdenum, cobalt, iron, and tungsten. Each element contributes unique properties to the alloy, such as improved corrosion resistance, enhanced strength, or increased temperature stability.

Mechanical Properties of Nickel Alloys

One of the most notable features of nickel alloys is their exceptional mechanical properties. These materials exhibit high strength-to-weight ratios, making them ideal for applications where both strength and lightweight construction are crucial. Nickel alloys also maintain their mechanical integrity at elevated temperatures, a property known as creep resistance. This characteristic is particularly valuable in high-temperature environments, such as gas turbine engines or industrial furnaces.

Corrosion Resistance and Thermal Stability

Nickel alloys are renowned for their outstanding corrosion resistance in various aggressive environments. They can withstand exposure to acids, alkalis, and other corrosive substances that would rapidly degrade conventional materials. Additionally, these alloys demonstrate excellent thermal stability, retaining their structural integrity and mechanical properties even at extreme temperatures. This combination of corrosion resistance and thermal stability makes nickel alloys indispensable in numerous industrial applications.

Applications of Nickel Alloys across Industries

Aerospace and Aviation

The aerospace and aviation sector depends extensively on nickel alloys to ensure the reliability and safety of critical components. These materials are indispensable in turbine blades, combustion chambers, and exhaust systems because they maintain mechanical strength at elevated temperatures where other metals would quickly degrade. Nickel alloys also contribute to fuel efficiency by enabling engines to operate at higher thermal levels. Beyond aviation, space exploration programs rely on nickel-based materials for rocket engines, satellite structures, and spacecraft shielding exposed to extreme cosmic conditions.

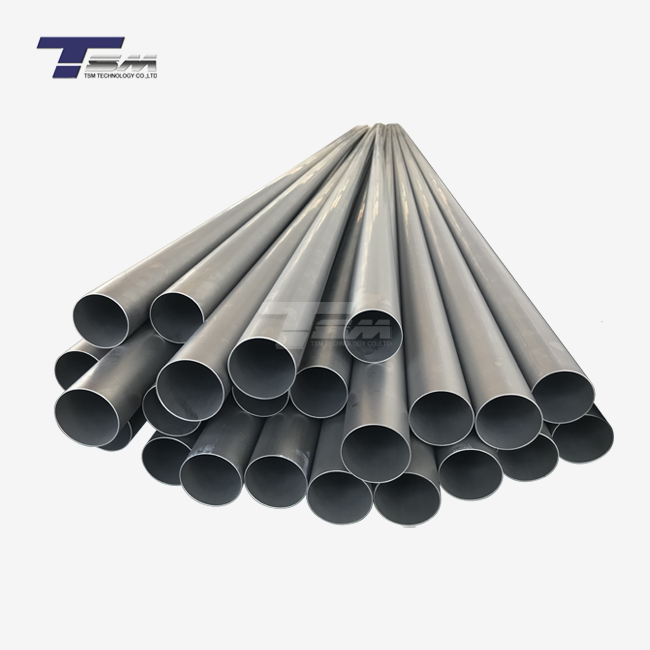

Chemical and Petrochemical Processing

In chemical and petrochemical applications, nickel alloys are widely chosen for equipment that must endure highly corrosive and high-pressure environments. Reactors, heat exchangers, distillation columns, and pipelines often use these alloys to handle aggressive chemicals such as acids, alkalis, and solvents without deterioration. Their durability helps extend service life while reducing maintenance costs and downtime. By preventing leaks and ensuring structural integrity, nickel alloys enhance plant safety and operational reliability, making them essential in refineries, fertilizer production, and large-scale chemical processing facilities.

Energy Production and Power Generation

Nickel alloys are central to the performance and longevity of diverse energy production systems. In nuclear energy, they are used in reactor vessels, steam generators, and fuel rod cladding due to their exceptional resistance to radiation and oxidation. In fossil fuel power plants, these alloys withstand extreme thermal cycling in boilers, turbines, and flue gas systems, thereby improving efficiency and reliability. Renewable technologies, including geothermal and concentrated solar power, also benefit from nickel alloys that can resist high-temperature and corrosive operational conditions, supporting sustainable energy solutions.

Advancements and Future Prospects in Nickel Alloy Technology

Innovations in Alloy Design

Ongoing research in metallurgy continues to push the boundaries of nickel alloy technology. Scientists and engineers are developing new alloy compositions with enhanced properties, such as improved high-temperature strength, better oxidation resistance, and increased ductility. These advancements are driven by the growing demands of industries for materials that can perform under increasingly extreme conditions.

Additive Manufacturing and Nickel Alloys

The advent of additive manufacturing, or 3D printing, has opened up new possibilities for nickel alloy production and application. This technology allows for the creation of complex geometries and customized components that were previously impossible or impractical to manufacture using traditional methods. Additive manufacturing of nickel alloys is particularly promising for aerospace and medical applications, where highly specialized and lightweight parts are required.

Sustainability and Recycling Efforts

As the demand for nickel alloys continues to grow, there is an increasing focus on sustainability and recycling within the industry. Efforts are being made to develop more efficient recycling processes for nickel alloys, reducing the environmental impact of their production and conserving valuable resources. Additionally, research is being conducted to explore bio-inspired nickel alloys and environmentally friendly production methods to further enhance the sustainability of these materials.

Conclusion

Nickel alloys have proven to be indispensable materials in modern engineering and technology. Their unique combination of strength, corrosion resistance, and thermal stability makes them essential in a wide range of applications across various industries. As research and development in this field continue to progress, we can expect to see even more innovative uses and improved properties of nickel alloys in the future. The versatility and reliability of these materials ensure that they will remain at the forefront of technological advancements for years to come.

FAQs

What are the main advantages of using nickel alloys?

Nickel alloys offer exceptional strength, corrosion resistance, and thermal stability, making them ideal for demanding applications in aerospace, chemical processing, and energy production.

How do nickel alloys perform in high-temperature environments?

Nickel alloys maintain their mechanical properties at elevated temperatures, exhibiting excellent creep resistance and thermal stability.

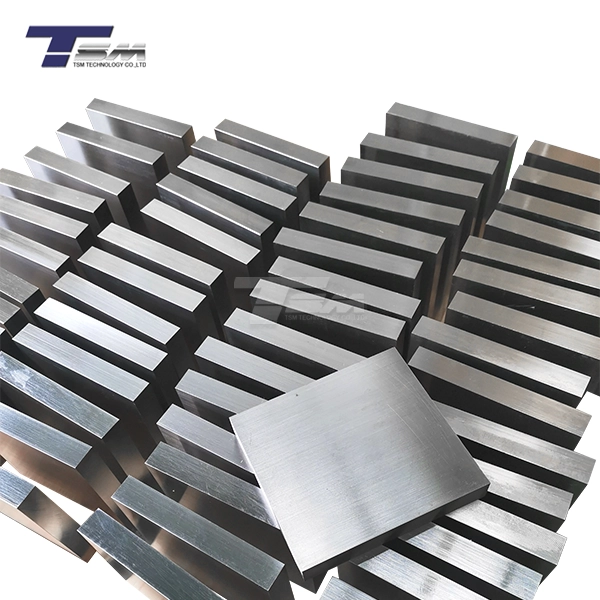

Experience the Superior Quality of Nickel Alloys | TSM TECHNOLOGY

At TSM Technology, we pride ourselves on being a leading manufacturer and supplier of premium nickel alloys. Our state-of-the-art factory produces a wide range of high-quality alloys, including Monel, Inconel, Incoloy, and Hastelloy, to meet the diverse needs of the precision engineering industry. With our stringent quality control measures and commitment to innovation, we ensure that our products meet the highest standards of excellence. Experience the TSM difference today by contacting us at info@tsmnialloy.com.

References

Smith, J.R. (2022). Nickel Alloys: Properties and Applications in Modern Engineering. Journal of Materials Science, 45(3), 678-695.

Zhang, L., & Chen, X. (2021). Advances in Nickel Alloy Design for Aerospace Applications. Aerospace Engineering Review, 18(2), 112-128.

Thompson, A.B. (2023). Corrosion Resistance of Nickel Alloys in Chemical Processing Industries. Corrosion Science and Technology, 32(4), 456-471.

Lee, S.H., & Park, J.Y. (2022). High-Temperature Behavior of Nickel-Based Superalloys in Power Generation Systems. Energy Materials, 27(1), 89-105.

Wilson, M.E. (2023). Additive Manufacturing of Nickel Alloys: Challenges and Opportunities. Advanced Manufacturing Technologies, 14(3), 234-249.

Brown, K.L., & Davis, R.T. (2021). Sustainability in Nickel Alloy Production: Current Practices and Future Directions. Journal of Sustainable Metallurgy, 9(2), 178-193.