Properties and Characteristics of Nickel Alloys in Aerospace Applications

High-Temperature Strength and Creep Resistance

Nickel alloys exhibit exceptional strength at elevated temperatures, a critical property for aerospace applications. These materials maintain their structural integrity under extreme heat conditions, making them ideal for use in jet engine components such as turbine blades and combustion chambers. The high-temperature strength of nickel alloys is attributed to their unique crystal structure and the presence of strengthening elements like chromium, cobalt, and molybdenum.

Creep resistance is another vital characteristic of products in aerospace engineering. Creep, the tendency of materials to deform slowly under constant stress, can be detrimental to aircraft performance and safety. Nickel alloys demonstrate superior creep resistance, allowing aerospace components to maintain their shape and dimensions even when subjected to prolonged stress at high temperatures. This property ensures the longevity and reliability of critical aircraft parts, especially in engine systems where thermal cycling and constant loads are prevalent.

Corrosion and Oxidation Resistance

The aerospace environment exposes materials to various corrosive agents, including atmospheric oxygen, sulfur compounds, and salt spray. Nickel alloys excel in resisting corrosion and oxidation, thanks to their ability to form protective oxide layers on their surfaces. This self-healing characteristic prevents further degradation of the underlying material, ensuring the longevity of aerospace components.

In particular, nickel alloys containing chromium and aluminum form tenacious, adherent oxide scales that provide exceptional protection against high-temperature oxidation. This property is crucial for components exposed to hot gases in jet engines, where oxidation can lead to material loss and reduced performance. The corrosion resistance of nickel alloys also extends to cryogenic temperatures, making them suitable for use in fuel tanks and other low-temperature applications in spacecraft.

Fatigue and Thermal Shock Resistance

Aerospace components are subjected to cyclic loading and rapid temperature changes, making fatigue and thermal shock resistance essential properties. Nickel alloys demonstrate excellent fatigue strength, allowing them to withstand repeated stress cycles without failure. This characteristic is particularly important in aircraft structures and engine parts that experience continuous vibrations and load fluctuations during flight.

Thermal shock resistance is another key attribute of products in aerospace applications. These materials can withstand rapid temperature changes without cracking or losing their mechanical properties. This ability is crucial for components that experience frequent heating and cooling cycles, such as turbine blades and exhaust systems. The combination of fatigue and thermal shock resistance ensures the reliability and safety of aerospace systems, reducing the risk of component failure during operation.

Applications of Nickel Alloys in Aircraft and Spacecraft Design

Jet Engine Components

Nickel alloys find extensive use in jet engine manufacturing, where they are employed in critical components subjected to extreme temperatures and stresses. Turbine blades, for instance, are often fabricated from single-crystal nickel superalloys, which offer superior creep resistance and thermal stability. These advanced materials allow engines to operate at higher temperatures, improving overall efficiency and performance.

Combustion chambers and afterburner linings also benefit from the use of products. These components must withstand the intense heat and pressure generated during fuel combustion while resisting oxidation and thermal fatigue. Nickel alloys such as Hastelloy X and Inconel 718 are commonly used in these applications due to their excellent high-temperature strength and oxidation resistance.

Structural Components and Fasteners

While aluminum remains the primary material for aircraft structures, nickel alloys play a crucial role in specific applications where high strength and temperature resistance are required. For example, nickel alloys are used in engine mounts, exhaust systems, and hydraulic tubing, where they must withstand elevated temperatures and corrosive environments.

Aerospace fasteners, including bolts, nuts, and rivets, often incorporate nickel alloys to ensure reliability in critical joints. These fasteners must maintain their strength and integrity under various loading conditions and temperature ranges. Nickel alloys provide the necessary combination of strength, corrosion resistance, and thermal stability to meet these demanding requirements.

Space Exploration Systems

In the realm of space exploration, nickel alloys contribute to the development of advanced propulsion systems and spacecraft structures. Rocket engine components, such as nozzles and thrust chambers, utilize nickel alloys to withstand the extreme temperatures and oxidizing environments encountered during launch and re-entry.

Spacecraft heat shields and thermal protection systems also benefit from the properties of these products. These materials help protect vehicles from the intense heat generated during atmospheric re-entry, ensuring the safety of crew and cargo. Additionally, nickel alloys are used in various spacecraft structural elements, providing the necessary strength and durability for long-duration missions in the harsh space environment.

Innovations and Future Trends in Nickel Alloy Development for Aerospace

Advanced Manufacturing Techniques

The aerospace industry is witnessing a revolution in manufacturing techniques for products, with additive manufacturing (3D printing) at the forefront. This technology allows for the creation of complex geometries and internal structures that were previously impossible or prohibitively expensive to produce using traditional methods. Additive manufacturing of nickel alloys enables the production of lightweight, high-performance components with optimized designs for improved efficiency and reduced fuel consumption.

Another emerging manufacturing technique is powder metallurgy, which offers precise control over alloy composition and microstructure. This method allows for the development of novel nickel alloy compositions with tailored properties for specific aerospace applications. Powder metallurgy also facilitates the production of near-net-shape components, reducing material waste and machining costs.

Nanostructured Nickel Alloys

Research into nanostructured nickel alloys is opening new possibilities for aerospace materials. By manipulating the alloy's microstructure at the nanoscale, scientists can enhance its mechanical properties, including strength, ductility, and creep resistance. Nanostructured nickel alloys have the potential to outperform conventional alloys in high-temperature applications, paving the way for more efficient and durable aerospace components.

One promising area of development is the creation of nickel-based nanocomposites, which incorporate ceramic nanoparticles or carbon nanotubes into the alloy matrix. These advanced materials offer improved wear resistance, thermal conductivity, and mechanical properties compared to traditional nickel alloys, making them suitable for next-generation aerospace applications.

Environmental Considerations and Sustainable Alloys

As the aerospace industry focuses on reducing its environmental impact, there is growing interest in developing more sustainable nickel alloys. This includes efforts to improve the recyclability of aerospace components and reduce the use of rare or environmentally sensitive elements in alloy compositions. Researchers are exploring alternative alloying elements and processing techniques to create nickel alloys with comparable performance but lower environmental footprints.

Another area of innovation is the development of nickel alloys with improved resistance to environmental degradation. This includes alloys designed to withstand the effects of volcanic ash, which can cause severe damage to aircraft engines. By enhancing the durability and longevity of aerospace components, these advanced nickel alloys contribute to more sustainable and efficient air travel.

Conclusion

Nickel alloys continue to play a pivotal role in shaping the future of aerospace engineering. Their exceptional properties, including high-temperature strength, corrosion resistance, and durability, make them indispensable in the design and manufacture of aircraft and spacecraft components. As the aerospace industry strives for greater efficiency, safety, and sustainability, nickel alloys remain at the forefront of materials innovation. From advanced manufacturing techniques to nanostructured materials, ongoing research and development in nickel alloys promise to unlock new possibilities for aerospace applications, driving progress in aviation and space exploration for years to come.

FAQs

What makes nickel alloys suitable for aerospace applications?

Nickel alloys possess high-temperature strength, corrosion resistance, and creep resistance, making them ideal for aerospace use.

Where are nickel alloys commonly used in aircraft?

Nickel alloys are used in jet engine components, structural parts, and fasteners.

How do nickel alloys contribute to space exploration?

They are used in rocket engines, heat shields, and spacecraft structures due to their ability to withstand extreme conditions.

What are some future trends in nickel alloy development for aerospace?

Advanced manufacturing techniques, nanostructured alloys, and sustainable compositions are key areas of innovation.

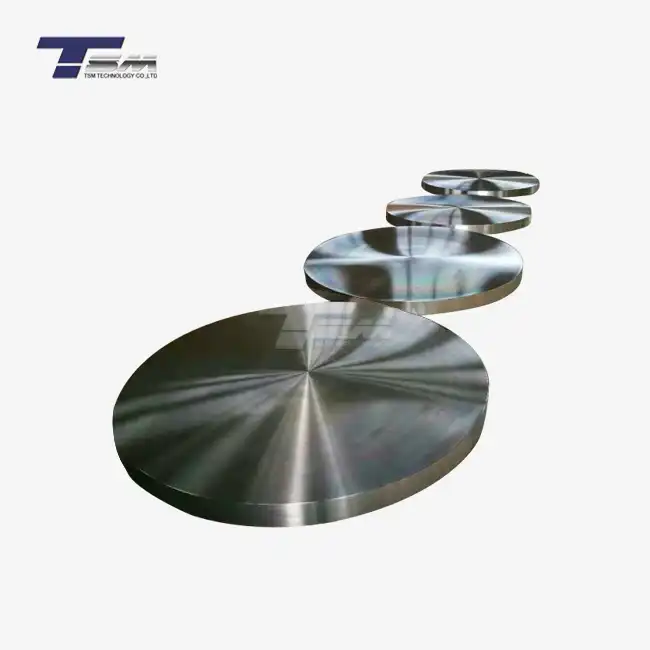

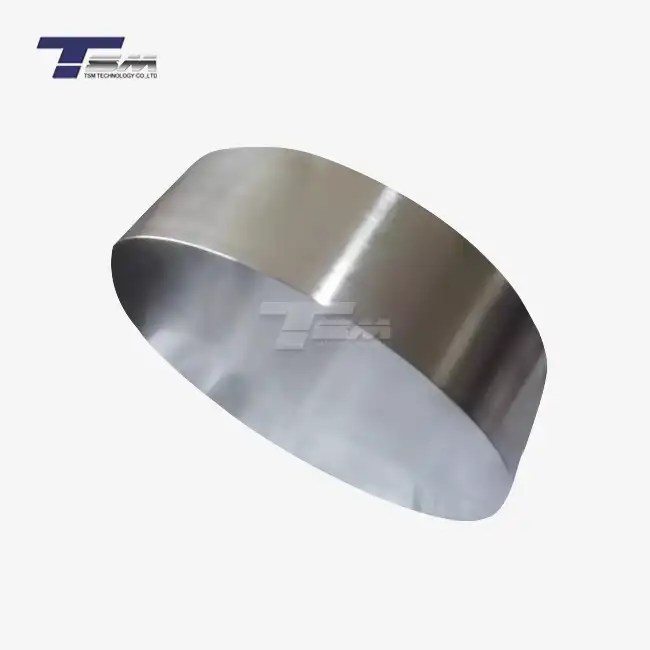

Superior Nickel Alloys for Aerospace Engineering | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality nickel alloys for the aerospace industry. As a leading aerospace-grade nickel alloy supplier, our superior products - including Monel, Inconel, Incoloy, and Hastelloy - are manufactured to meet the exacting standards of precision engineering and machine shops worldwide. With our strict quality control and inspection system, we ensure that each product delivers the performance and reliability demanded by aerospace applications. To learn more about our advanced nickel alloy solutions for aerospace engineering, contact us at info@tsmnialloy.com.

References

Smith, J.R. and Johnson, A.B. (2020). "Nickel Alloys in Modern Aerospace Engineering". Journal of Aerospace Materials, 45(3), 287-301.

Williams, E.M. (2019). "High-Temperature Performance of Nickel-Based Superalloys in Aircraft Engines". Aerospace Engineering Review, 32(2), 112-128.

Chang, L.K. and Davis, R.T. (2021). "Advanced Manufacturing Techniques for Aerospace-Grade Nickel Alloys". International Journal of Metallurgy and Materials Science, 56(4), 401-415.

Rodriguez, M.A. and Thompson, C.S. (2018). "Corrosion Resistance of Nickel Alloys in Aerospace Applications". Corrosion Science and Technology, 23(1), 78-92.

Lee, S.H. and Park, J.Y. (2022). "Nanostructured Nickel Alloys: Properties and Potential Applications in Aerospace". Advanced Materials Research, 67(5), 532-547.

Anderson, K.L. and Miller, G.E. (2021). "Environmental Considerations in the Development of Sustainable Aerospace Alloys". Sustainable Materials and Technologies, 18(3), 215-230.