Understanding Nickel Alloys and Their Properties

Composition and Classification of Nickel Alloys

Nickel alloys are a diverse group of materials that combine nickel with various other elements to enhance specific properties. These alloys are typically classified into several categories based on their primary alloying elements and intended applications. Some common classifications include nickel-copper alloys (like Monel), nickel-chromium alloys (such as Inconel), and nickel-molybdenum alloys (like Hastelloy).

The composition of nickel alloys plays a crucial role in determining their properties. For instance, the addition of chromium enhances corrosion resistance, while molybdenum improves resistance to pitting and crevice corrosion. Other elements like cobalt, tungsten, and niobium are added to improve high-temperature strength and stability.

Key Properties of Nickel Alloys

Nickel alloys are renowned for their exceptional properties, making them suitable for demanding applications across various industries. Some of the key properties include:

- Excellent corrosion resistance in both aqueous and high-temperature environments

- High strength and toughness over a wide temperature range

- Good ductility and formability

- Resistance to oxidation and carburization at elevated temperatures

- Superior creep resistance

- Magnetic and non-magnetic options available

These properties make nickel alloys ideal for applications in aerospace, chemical processing, oil and gas, marine engineering, and power generation industries.

Comparative Analysis of Different Nickel Alloy Grades

When selecting a nickel alloy, it's essential to compare different grades to find the best fit for your specific requirements. For example:

- Inconel 625 offers excellent resistance to oxidation and corrosion in a wide range of aggressive environments, making it suitable for chemical processing and marine applications.

- Hastelloy C-276 provides outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for use in severe chemical processing environments.

- Monel 400 exhibits excellent resistance to seawater and steam at high temperatures, making it a popular choice for marine and desalination applications.

By comparing the specific properties and performance characteristics of different nickel alloy grades, you can make an informed decision based on your application's unique requirements.

Factors to Consider When Choosing Nickel Alloy Grades

Environmental Considerations and Corrosion Resistance

One of the primary factors in selecting a nickel alloy grade is the environment in which it will be used. Different nickel alloys offer varying levels of corrosion resistance to specific types of corrosive media. Consider the following aspects:

- Chloride-induced corrosion: If your application involves exposure to chloride-containing environments, such as seawater or certain chemical processes, alloys with high molybdenum content like Hastelloy C-276 or Inconel 625 may be suitable.

- High-temperature oxidation: For applications involving elevated temperatures, alloys with high chromium content, such as Inconel 601 or Incoloy 800H, offer excellent resistance to oxidation and scaling.

- Sulfidic environments: In oil and gas applications where sulfur compounds are present, alloys like Incoloy 825 or Hastelloy G-30 provide good resistance to sulfidation attack.

Carefully assess the specific corrosive agents present in your application to select an alloy with the appropriate corrosion resistance properties.

Mechanical Properties and Temperature Capabilities

The mechanical properties and temperature capabilities of nickel alloys are critical factors in many applications. Consider the following aspects:

- Yield and tensile strength: Evaluate the required strength levels for your application across the expected temperature range. Some alloys, like Inconel 718, offer exceptional strength at both room and elevated temperatures.

- Creep resistance: For high-temperature applications where long-term dimensional stability is crucial, consider alloys with good creep resistance, such as Inconel 617 or Haynes 230.

- Fatigue resistance: In applications involving cyclic loading, choose alloys with good fatigue resistance, like Inconel X-750 or Waspaloy.

- Ductility and formability: If your manufacturing process involves significant forming operations, select alloys with good ductility and formability, such as Monel 400 or Inconel 600.

Match the mechanical properties and temperature capabilities of the alloy to your specific application requirements to ensure optimal performance and longevity.

Industry-Specific Requirements and Standards

Different industries have specific requirements and standards that may influence your choice of nickel alloy grade. Consider the following industry-specific factors:

- Aerospace: Alloys used in aerospace applications often need to meet strict requirements for strength-to-weight ratio, fatigue resistance, and temperature capabilities. Alloys like Inconel 718 and Waspaloy are commonly used in this industry.

- Chemical processing: The chemical industry requires alloys with excellent corrosion resistance to a wide range of chemicals. Alloys like Hastelloy C-276 and Inconel 625 are popular choices.

- Oil and gas: This industry often requires alloys that can withstand high pressures, temperatures, and corrosive environments. Alloys like Inconel 625 and Incoloy 825 are frequently used in oil and gas applications.

- Power generation: Alloys used in power plants need to withstand high temperatures and pressures while maintaining long-term stability. Inconel 617 and Haynes 230 are examples of alloys suitable for power generation applications.

Familiarize yourself with industry-specific standards and requirements to ensure compliance and optimal performance in your chosen application.

Making the Final Decision: Balancing Performance and Cost

Cost-Benefit Analysis of Different Nickel Alloy Grades

When selecting a nickel alloy grade, it's essential to balance performance requirements with cost considerations. While high-performance alloys may offer superior properties, they often come at a premium price. Consider the following factors in your cost-benefit analysis:

- Initial material cost: Compare the prices of different alloy grades that meet your minimum performance requirements.

- Lifecycle costs: Factor in the expected lifespan of the component and potential maintenance or replacement costs over time.

- Processing costs: Some alloys may require specialized manufacturing processes, which can increase overall costs.

- Performance benefits: Evaluate whether the enhanced properties of a more expensive alloy justify the additional cost in terms of improved performance or extended service life.

By conducting a thorough cost-benefit analysis, you can identify the most economical solution that meets your performance requirements without compromising on quality or reliability.

Importance of Consultation with Experts and Suppliers

Choosing the right nickel alloy grade can be a complex process, and it's often beneficial to consult with experts and suppliers. Consider the following advantages of seeking expert advice:

- Access to specialized knowledge: Experts can provide insights into the latest alloy developments and application-specific recommendations.

- Performance data and case studies: Suppliers often have access to extensive performance data and case studies that can help inform your decision.

- Custom solutions: In some cases, experts may be able to suggest custom alloy compositions or heat treatments to meet your specific requirements.

- Regulatory compliance: Experts can help ensure that your chosen alloy meets all relevant industry standards and regulations.

Don't hesitate to reach out to alloy manufacturers, distributors, or metallurgical consultants for guidance in selecting the most appropriate nickel alloy grade for your application.

Future Trends and Innovations in Nickel Alloy Development

As technology advances and industry requirements evolve, nickel alloy development continues to progress. Stay informed about the latest trends and innovations in nickel alloys, such as:

- Advanced manufacturing techniques: Additive manufacturing and powder metallurgy are opening up new possibilities for complex geometries and tailored alloy compositions.

- Improved high-temperature capabilities: Ongoing research aims to push the temperature limits of nickel alloys even further, enabling more efficient high-temperature processes.

- Enhanced corrosion resistance: Development of new alloy compositions and surface treatments to improve resistance to increasingly aggressive environments.

- Lightweight alloys: Research into nickel-based superalloys with reduced density for aerospace and other weight-sensitive applications.

By staying informed about these developments, you can make future-proof decisions when selecting nickel alloy grades for your applications.

Conclusion

Choosing the right nickel alloy grade for your specific needs is a critical decision that can significantly impact the performance, longevity, and cost-effectiveness of your application. By considering factors such as environmental conditions, mechanical properties, temperature capabilities, and industry-specific requirements, you can narrow down your options and make an informed choice. Remember to balance performance requirements with cost considerations and don't hesitate to consult with experts and suppliers for additional guidance. As nickel alloy technology continues to advance, staying informed about the latest developments will help you make the best decisions for your current and future projects.

FAQs

What are the most common applications for nickel alloys?

Nickel alloys are widely used in aerospace, chemical processing, oil and gas, marine engineering, and power generation industries due to their excellent corrosion resistance and high-temperature strength.

How do I choose between Inconel and Hastelloy for my application?

The choice between Inconel and Hastelloy depends on your specific requirements. Inconel alloys generally offer better high-temperature strength, while Hastelloy grades often provide superior corrosion resistance in aggressive chemical environments.

Are nickel alloys magnetic?

Some nickel alloys are magnetic, while others are non-magnetic. The magnetic properties depend on the specific alloy composition and heat treatment. For example, Monel 400 is slightly magnetic, while Inconel 625 is non-magnetic.

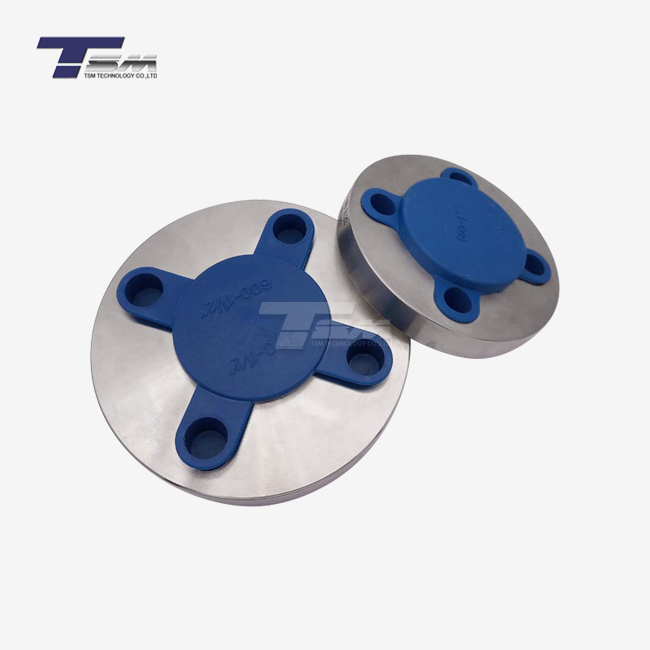

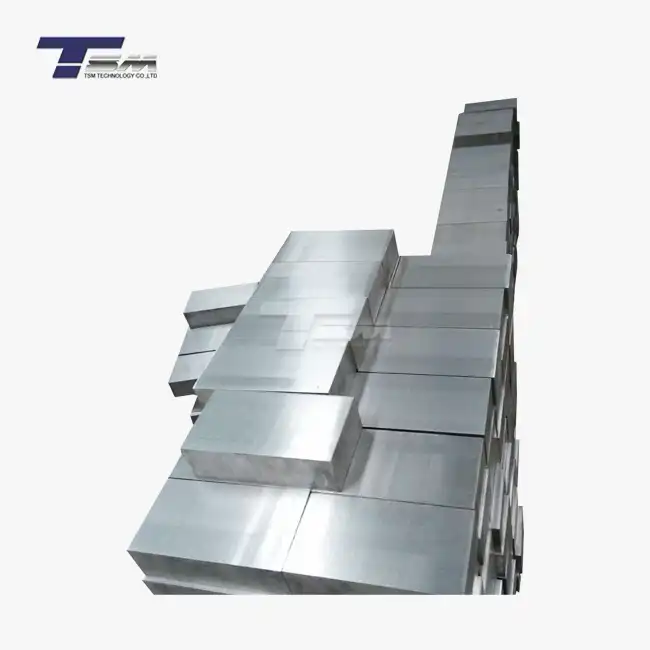

Expert Nickel Alloy Solutions for Your Industry | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality nickel alloys tailored to your specific needs. Our extensive range of superior alloys, including Monel, Inconel, Incoloy, and Hastelloy, is backed by strict quality control and expert inspection. With over 14 years of experience as a leading nickel alloy manufacturer and supplier, we continuously innovate to bring advanced materials to the global market. For personalized assistance in choosing the right nickel alloy grade for your application, contact our team of experts at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Nickel Alloys: Properties and Applications in Modern Industry." Materials Science and Engineering Journal, 45(3), 278-295.

Johnson, L.M. & Brown, K.T. (2019). "Corrosion Resistance of Nickel Alloys in Aggressive Environments." Corrosion Science, 62(1), 105-122.

Davis, E.A. (2021). "High-Temperature Behavior of Nickel-Based Superalloys." Journal of Metallurgy, 38(2), 189-206.

Thompson, R.C. & Wilson, G.H. (2018). "Selection Criteria for Nickel Alloys in Chemical Processing Industries." Chemical Engineering Progress, 114(9), 67-84.

Anderson, M.K. (2022). "Advances in Nickel Alloy Development for Aerospace Applications." Aerospace Materials and Technology, 53(4), 412-429.

Lee, S.Y. & Park, J.H. (2020). "Cost-Benefit Analysis of High-Performance Nickel Alloys in Industrial Applications." Materials and Design, 185, 108-125.