Thermal Properties and Stress Resistance of Inconel 600

Thermal Expansion Characteristics

Inconel 600 round bars exhibit controlled thermal expansion, a crucial factor in their performance under thermal stress. The alloy's coefficient of thermal expansion remains relatively low and stable across a wide temperature range, minimizing dimensional changes and associated stresses in high-temperature applications. This property ensures that components manufactured from alloy 600 round bars maintain their precise dimensions and fits, even when subjected to repeated heating and cooling cycles.

Heat Capacity and Thermal Conductivity

The heat capacity of Inconel 600 bars plays a significant role in their thermal stress resistance. The alloy's ability to absorb and distribute heat efficiently helps prevent localized hot spots and reduces thermal gradients within the material. Additionally, the moderate thermal conductivity of Inconel 600 allows for controlled heat transfer, contributing to its overall thermal stability and stress resistance in demanding environments.

Microstructural Stability at Elevated Temperatures

One of the key factors contributing to the exceptional performance of Inconel 600 under thermal stress is its microstructural stability at high temperatures. The alloy's face-centered cubic crystal structure and carefully balanced composition resist phase transformations and precipitation hardening, maintaining its strength and ductility even after prolonged exposure to elevated temperatures. This microstructural stability ensures that Inconel 600 round bars retain their mechanical properties and resist creep deformation under sustained thermal loads.

Mechanical Behavior of Inconel 600 Under Thermal Stress

Yield Strength and Tensile Properties

Inconel 600 bars demonstrate impressive yield strength and tensile properties at elevated temperatures, contributing to their excellent performance under thermal stress. The alloy maintains a significant portion of its room temperature strength even at temperatures exceeding 1000°F (538°C). This retention of mechanical properties ensures that components manufactured from alloy 600 round bars can withstand high stresses and loads in hot environments without experiencing premature failure or excessive deformation.

Creep Resistance and Rupture Strength

The creep resistance of Inconel 600 is a critical factor in its performance under sustained thermal stress. The alloy exhibits exceptional resistance to time-dependent deformation, maintaining dimensional stability and structural integrity over extended periods at high temperatures. This property is particularly valuable in applications such as heat exchangers and pressure vessels, where Inconel 600 round bar ensures long-term reliability under constant thermal and mechanical loads.

Fatigue Behavior Under Thermal Cycling

Thermal fatigue resistance is a hallmark of Inconel 600's performance under fluctuating temperature conditions. The alloy's ability to withstand repeated thermal cycling without significant degradation in mechanical properties makes it ideal for components subjected to frequent temperature changes. This resistance to thermal fatigue ensures the longevity and reliability of Inconel 600 round bars in applications such as gas turbine components and exhaust systems, where thermal cycling is a common occurrence.

Applications Leveraging Inconel 600's Thermal Stress Performance

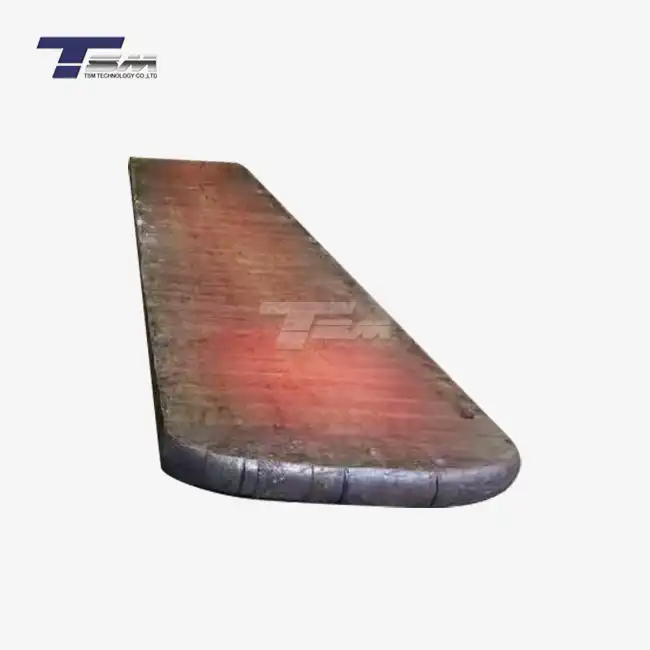

Aerospace and Gas Turbine Components

The aerospace industry extensively utilizes Inconel 600 bars in the manufacture of critical components exposed to extreme thermal stresses. Gas turbine engine parts, such as combustion chambers, turbine blades, and exhaust systems, benefit from the alloy's ability to maintain strength and resist oxidation at high temperatures. The thermal stress resistance of Inconel 600 round bars ensures the safe and efficient operation of aircraft engines under demanding conditions.

Nuclear Power Generation

In nuclear power plants, alloy 600 round bars find application in various components subjected to intense thermal and radiation environments. The material's resistance to corrosion, stress corrosion cracking, and thermal fatigue makes it suitable for steam generator tubing, control rod drive mechanisms, and other critical reactor internals. The reliable performance of Inconel 600 under thermal stress contributes to the safety and longevity of nuclear power facilities.

Chemical Processing Equipment

The chemical processing industry relies on Inconel 600 bars for the construction of reactors, heat exchangers, and piping systems exposed to corrosive media at elevated temperatures. The alloy's combination of excellent corrosion resistance and thermal stress performance ensures the integrity of process equipment in aggressive chemical environments. This reliability translates to improved operational efficiency and reduced maintenance costs in chemical manufacturing operations.

Conclusion

Inconel 600's exceptional performance under thermal stress positions it as a premier material for high-temperature applications across various industries. Its unique combination of thermal stability, mechanical strength retention, and resistance to environmental degradation makes it an invaluable alloy for critical components operating in extreme conditions. As engineering challenges continue to push the boundaries of material capabilities, Inconel 600 round bars and Inconel 600 bars remain at the forefront, enabling technological advancements and ensuring reliability in the most demanding thermal environments.

Contact Us

For more information about Inconel 600 and its performance under thermal stress, or to explore our range of superior nickel alloys, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the ideal alloy for your specific application needs.