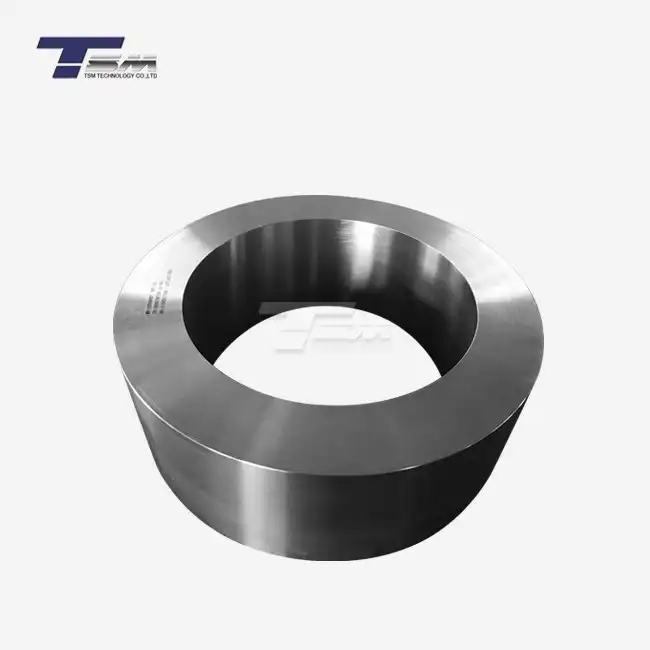

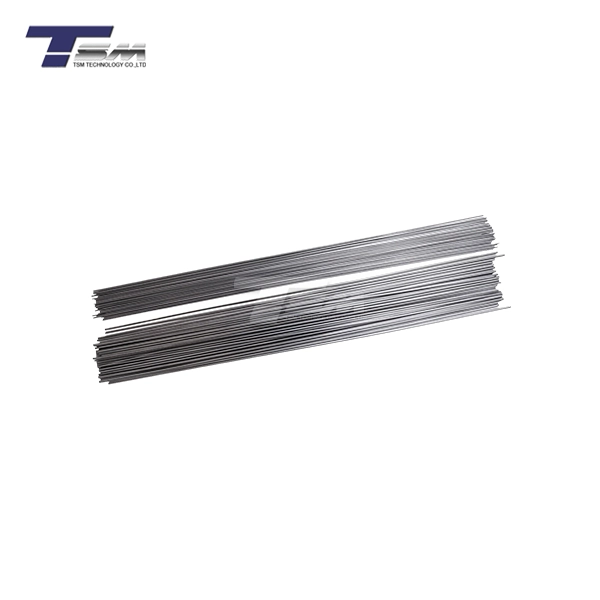

Understanding the Unique Properties of Inconel 600

Chemical Composition and Microstructure

Inconel 600, also known as alloy 600, boasts a carefully balanced chemical composition that contributes to its exceptional performance. The alloy typically contains 72% nickel, 14-17% chromium, and 6-10% iron, along with trace amounts of other elements. This composition results in a face-centered cubic austenitic structure, which imparts excellent ductility and toughness. The high nickel content enhances the alloy's resistance to various forms of corrosion, while the chromium provides oxidation resistance through the formation of a protective oxide layer.

Mechanical Properties at Elevated Temperatures

One of the most remarkable aspects of Inconel 600 round bars is their ability to maintain mechanical properties at high temperatures. The alloy exhibits impressive tensile strength, yield strength, and creep resistance even when exposed to temperatures exceeding 1000°C (1832°F). This thermal stability is crucial for applications where components must withstand prolonged exposure to extreme heat without compromising structural integrity. The alloy's resistance to thermal fatigue and thermal shock further enhances its suitability for cyclic temperature environments.

Non-Magnetic Characteristics and Their Significance

The non-magnetic nature of Inconel 600 bars is a key attribute that sets it apart from many other high-temperature alloys. This property is particularly valuable in applications where magnetic interference could disrupt sensitive equipment or processes. In industries such as electronics manufacturing and scientific research, the use of non-magnetic Inconel 600 components ensures precise measurements and reliable operation of magnetic-sensitive instruments. Additionally, the alloy's non-magnetic behavior remains consistent across a wide temperature range, making it ideal for use in high-temperature environments where magnetic properties might otherwise change.

Applications of Inconel 600 in High-Temperature Industries

Aerospace and Gas Turbine Components

The aerospace industry relies heavily on Inconel 600 round bars for critical components in gas turbine engines. Turbine blades, combustion chambers, and exhaust systems benefit from the alloy's exceptional heat resistance and strength retention at elevated temperatures. Inconel 600's ability to withstand thermal cycling and resist oxidation makes it an ideal choice for these demanding applications. The material's non-magnetic properties also contribute to the overall performance and reliability of aerospace systems, particularly in areas where electromagnetic interference must be minimized.

Chemical Processing Equipment

In the chemical processing industry, Inconel 600 bars find extensive use in the construction of reactors, heat exchangers, and piping systems. The alloy's excellent corrosion resistance to a wide range of aggressive chemicals, combined with its high-temperature stability, makes it invaluable for handling corrosive substances at elevated temperatures. Distillation columns, pressure vessels, and catalytic crackers often incorporate Inconel 600 components to ensure long-term reliability and minimal downtime in harsh operating conditions.

Nuclear Power Generation

The nuclear power industry relies on alloy 600 round bars for various critical components within reactor systems. Steam generator tubing, control rod drive mechanisms, and core internals benefit from Inconel 600's resistance to radiation-induced corrosion and its ability to maintain structural integrity in high-temperature, high-pressure environments. The non-magnetic nature of the alloy is particularly advantageous in nuclear applications, as it helps prevent interference with sensitive instrumentation and control systems crucial for safe reactor operation.

Advantages of Using Inconel 600 in High-Temperature Applications

Corrosion Resistance in Extreme Environments

One of the primary advantages of utilizing Inconel 600 round bars in high-temperature applications is their exceptional corrosion resistance. The alloy's high nickel content and chromium-rich oxide layer protect against a wide range of corrosive media, including oxidizing and reducing atmospheres, molten salts, and organic compounds. This resistance to corrosion ensures extended service life and reduced maintenance requirements for components exposed to harsh chemical environments at elevated temperatures. In industries such as petrochemical processing and waste incineration, where corrosive gases and high temperatures coexist, Inconel 600 proves invaluable in maintaining equipment integrity and process efficiency.

Thermal Stability and Dimensional Consistency

Inconel 600 bars exhibit remarkable thermal stability, maintaining their mechanical properties and dimensional consistency across a wide temperature range. This characteristic is crucial for applications where precise tolerances must be maintained despite frequent thermal cycling or prolonged exposure to high temperatures. The alloy's low coefficient of thermal expansion compared to many other materials further enhances its dimensional stability, reducing the risk of warping or distortion in critical components. This property is particularly beneficial in applications such as furnace equipment, where maintaining precise geometries is essential for optimal performance and energy efficiency.

Long-Term Reliability and Cost-Effectiveness

While the initial cost of Inconel 600 may be higher than some alternative materials, its long-term reliability and performance in high-temperature applications often result in significant cost savings over the life of the equipment. The alloy's resistance to creep, fatigue, and thermal shock translates to reduced maintenance requirements, fewer replacements, and extended service intervals. In industries where downtime is extremely costly, such as power generation or aerospace, the use of alloy 600 round bars can lead to substantial operational savings and improved overall efficiency. Furthermore, the material's ability to withstand extreme conditions often allows for the design of more compact and efficient systems, potentially reducing material usage and associated costs in the long run.

Conclusion

Non-magnetic Inconel 600 stands out as a superior material for high-temperature applications, offering a unique combination of properties that benefit various industries. Its exceptional heat resistance, corrosion resistance, and non-magnetic characteristics make it an ideal choice for demanding environments. From aerospace to chemical processing and nuclear power generation, Inconel 600 round bars and Inconel 600 bars continue to play a crucial role in advancing technology and improving industrial processes. As industries push the boundaries of performance and efficiency, the reliability and versatility of alloy 600 round bars ensure their continued relevance in high-temperature applications for years to come.

Contact Us

For more information about our high-quality Inconel 600 products and how they can benefit your high-temperature applications, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.