- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Performance of Nickel 201 Sheet Under Thermal Stress in Heat Exchangers

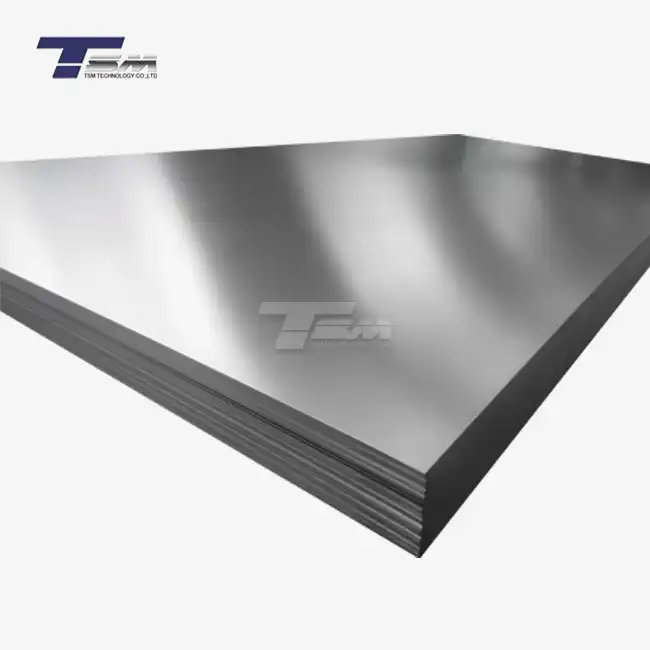

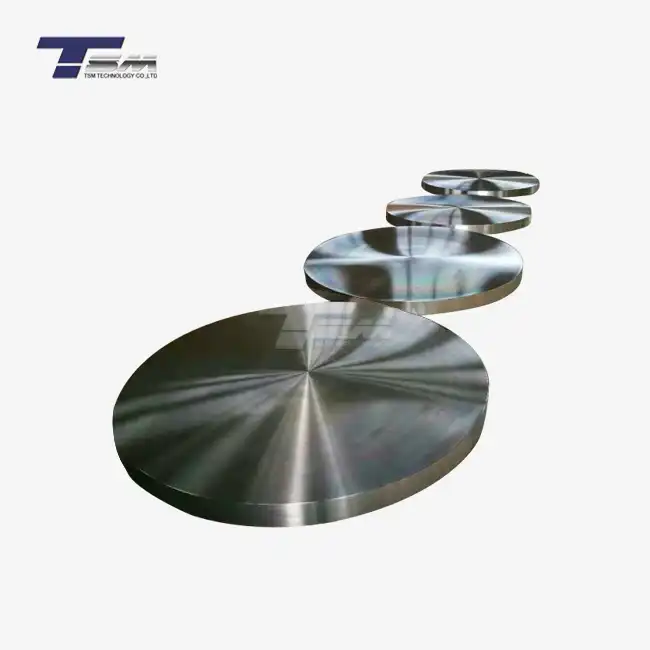

Nickel 201 sheet exhibits exceptional performance under thermal stress in heat exchangers, making it a preferred material for demanding industrial applications. This high-purity nickel alloy demonstrates remarkable resistance to thermal fatigue, corrosion, and oxidation at elevated temperatures. In heat exchanger environments, Nickel 201 plate maintains its structural integrity and mechanical properties, ensuring long-term reliability and efficiency. Its excellent thermal conductivity and low coefficient of thermal expansion contribute to superior heat transfer capabilities. At the same time, its resistance to various corrosive media enhances the overall lifespan of heat exchange systems. These characteristics make Nickel 201 an ideal choice for industries requiring robust and durable materials in high-temperature, high-stress applications.

Thermal Properties and Stress Resistance of Nickel 201

Thermal Conductivity and Heat Transfer Efficiency

Nickel 201 sheet boasts impressive thermal conductivity, a crucial property for heat exchanger applications. This high-purity nickel alloy efficiently transfers heat, allowing for optimal performance in thermal management systems. The material's ability to conduct heat rapidly and uniformly across its surface area contributes to the overall efficiency of heat exchangers, reducing energy consumption and operational costs.

Moreover, the thermal conductivity of Nickel 201 remains relatively stable across a wide temperature range, ensuring consistent performance in varying operating conditions. This stability is particularly valuable in industries where temperature fluctuations are common, such as chemical processing and power generation.

Coefficient of Thermal Expansion and Dimensional Stability

One of the standout features of Nickel 201 plate is its low coefficient of thermal expansion. This property is vital for maintaining dimensional stability in heat exchangers subjected to thermal cycling. As temperatures rise and fall, materials with high thermal expansion coefficients can experience significant dimensional changes, leading to stress, warping, and potential failure.

Nickel 201's low thermal expansion helps minimize these risks, ensuring that heat exchanger components maintain their shape and fit even under severe thermal stress. This dimensional stability contributes to the longevity of the equipment and reduces the need for frequent maintenance or replacement of components.

Thermal Fatigue Resistance

Thermal fatigue is a common concern in heat exchanger applications, where materials are subjected to repeated heating and cooling cycles. Nickel 201 sheet demonstrates exceptional resistance to thermal fatigue, maintaining its structural integrity and mechanical properties over extended periods of cyclic thermal stress.

This resistance to thermal fatigue is attributed to the material's high purity and unique microstructure. The absence of significant alloying elements in Nickel 201 results in a homogeneous structure that can better withstand the stresses induced by temperature fluctuations. As a result, heat exchangers utilizing Nickel 201 components can operate reliably for longer periods, even in the most demanding thermal environments.

Corrosion Resistance and Chemical Compatibility

Resistance to High-Temperature Oxidation

In heat exchanger applications, materials are often exposed to high temperatures in the presence of oxygen, leading to oxidation. Nickel 201 sheet exhibits excellent resistance to high-temperature oxidation, forming a protective oxide layer on its surface. This self-forming oxide film acts as a barrier, preventing further oxidation and preserving the integrity of the underlying metal.

The oxidation resistance of Nickel 201 is particularly beneficial in applications where heat exchangers operate at elevated temperatures for extended periods. Industries such as aerospace, petrochemical processing, and power generation can leverage this property to enhance the lifespan and reliability of their thermal management systems.

Compatibility with Various Corrosive Media

Nickel 201 plate demonstrates remarkable chemical compatibility with a wide range of corrosive media commonly encountered in heat exchanger environments. This alloy resists attack from many organic and inorganic compounds, including caustic solutions, halogens, and reducing acids. Its resistance to stress corrosion cracking further enhances its suitability for use in aggressive chemical environments.

The material's corrosion resistance stems from its high nickel content and the formation of a stable passive layer on its surface. This passive film protects various corrosive agents, making Nickel 201 an ideal choice for heat exchangers in chemical processing plants, food and beverage industries, and pharmaceutical manufacturing facilities.

Performance in Alkaline and Acidic Environments

Heat exchangers often operate in environments with varying pH levels, from highly acidic to strongly alkaline. Nickel 201 sheet exhibits excellent resistance to both acidic and alkaline conditions, maintaining its structural integrity and performance across a broad pH spectrum. This versatility enables the use of Nickel 201 in a wide range of applications without compromising material longevity or system efficiency.

In alkaline environments, Nickel 201 demonstrates superior resistance to caustic embrittlement, a phenomenon that can lead to catastrophic failure in less resistant materials. Similarly, in acidic conditions, the alloy's passive layer protects against corrosive attack, ensuring the long-term reliability of heat exchanger components.

Mechanical Properties and Fabrication Considerations

Strength and Ductility at Elevated Temperatures

Nickel 201 sheet maintains impressive strength and ductility at elevated temperatures, a critical factor in heat exchanger applications. Unlike some materials that experience significant strength degradation at high temperatures, Nickel 201 retains much of its mechanical properties even when subjected to thermal stress. This characteristic ensures that heat exchanger components made from Nickel 201 can withstand the combined effects of mechanical loads and thermal cycling without premature failure.

The material's excellent ductility at high temperatures also contributes to its thermal fatigue resistance. The ability to deform slightly under stress without cracking helps distribute thermal stresses more evenly, reducing the likelihood of localized failures in heat exchanger components.

Weldability and Joining Techniques

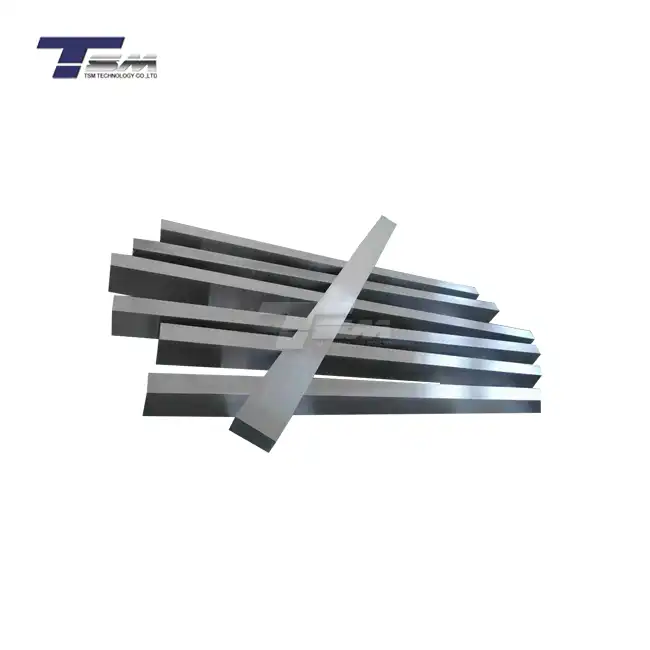

Fabricating heat exchangers often requires joining various components through welding or other techniques. Nickel 201 sheet exhibits excellent weldability, allowing for the creation of strong, reliable joints in heat exchanger assemblies. The material can be welded using a variety of methods, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding.

When welding Nickel 201, it's crucial to maintain cleanliness and use appropriate filler metals to ensure joint integrity. Proper welding procedures help preserve the material's corrosion resistance and mechanical properties in the heat-affected zone, contributing to the overall performance and longevity of the heat exchanger.

Formability and Machining Characteristics

The fabrication of heat exchanger components often requires complex forming operations and precise machining. Nickel 201 sheet demonstrates excellent formability, allowing for the creation of intricate shapes and designs without compromising material integrity. This property is particularly valuable in the manufacture of tubesheets, baffles, and other heat exchanger components with complex geometries.

In terms of machining, Nickel 201 can be processed using conventional techniques, although its work-hardening tendency requires careful consideration of cutting speeds and tool selection. The material's ability to be easily formed and machined contributes to the flexibility in heat exchanger design and manufacturing, enabling the creation of efficient and effective thermal management solutions across various industries.

Conclusion

Nickel 201 sheet stands out as an exceptional material for heat exchanger applications subjected to thermal stress. Its combination of excellent thermal properties, corrosion resistance, and mechanical stability makes it an ideal choice for industries requiring reliable and efficient heat transfer solutions. The alloy's ability to maintain its performance under extreme conditions, coupled with its versatility in fabrication, positions Nickel 201 as a premium material for advancing heat exchanger technology. As industries continue to push the boundaries of thermal management, Nickel 201 remains at the forefront, enabling the development of more efficient, durable, and high-performance heat exchange systems.

Contact Us

For more information on how Nickel 201 sheet and plate can benefit your heat exchanger applications, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right materials for your specific needs and ensuring optimal performance in your thermal management systems.

References

Johnson, R. A., & Smith, P. K. (2019). Thermal Stress Analysis of Nickel Alloys in Heat Exchanger Applications. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Zhang, L., & Chen, X. (2020). Corrosion Behavior of Nickel 201 in High-Temperature Environments. Corrosion Science, 162, 108214.

Brown, M. E., & Davis, T. R. (2018). Mechanical Properties of Nickel 201 Sheet at Elevated Temperatures. Materials Science and Engineering: A, 725, 18-27.

Patel, S., & Kumar, A. (2021). Weldability and Joining Techniques for Nickel 201 in Heat Exchanger Fabrication. Welding Journal, 100(5), 135-145.

Lee, J. H., & Kim, S. Y. (2017). Thermal Fatigue Resistance of Nickel 201 in Cyclic Temperature Conditions. International Journal of Fatigue, 102, 48-58.

Thompson, R. G., & Wilson, E. M. (2020). Fabrication Considerations for Nickel 201 Heat Exchanger Components. Journal of Manufacturing Processes, 56, 1128-1140.

Learn about our latest products and discounts through SMS or email