- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Nickel 201 Sheet is Ideal for High-Temperature Vacuum Furnaces?

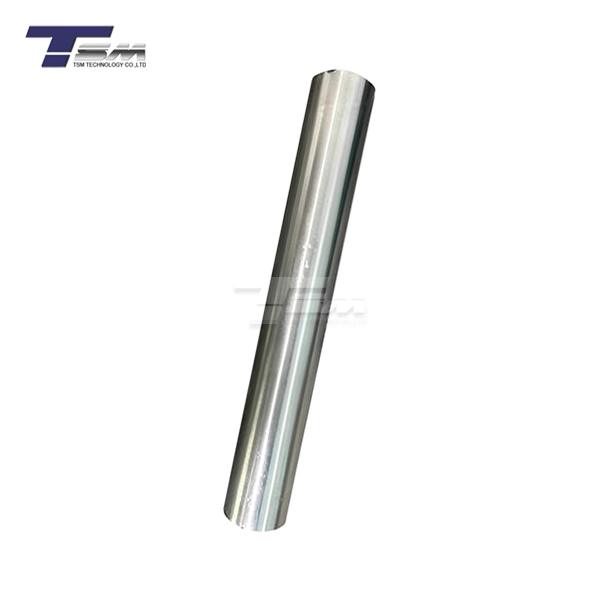

Nickel 201 sheet stands out as the premier choice for high-temperature vacuum furnaces due to its exceptional thermal stability, corrosion resistance, and mechanical properties. This remarkable alloy maintains its structural integrity and performance even under extreme heat and vacuum conditions, making it indispensable in various industrial applications. The unique combination of high purity nickel content and carefully controlled alloying elements in Nickel 201 plate ensures optimal heat transfer, minimal outgassing, and superior durability in vacuum environments. These characteristics make Nickel 201 sheet the go-to material for engineers and manufacturers seeking reliable, long-lasting components in high-temperature vacuum furnace systems.

Unparalleled Thermal Performance of Nickel 201 Sheet in Vacuum Environments

Heat Resistance and Stability at Extreme Temperatures

Nickel 201 sheet exhibits remarkable heat resistance, maintaining its structural integrity and mechanical properties at temperatures up to 1800°F (982°C). This extraordinary thermal stability stems from its high nickel content, typically exceeding 99%. The alloy's crystal structure remains stable even under prolonged exposure to extreme heat, preventing unwanted deformation or phase transformations that could compromise the vacuum furnace's performance.

Moreover, Nickel 201 plate demonstrates excellent dimensional stability across a wide temperature range. This characteristic is crucial in vacuum furnace applications, where precise control of component dimensions is essential for maintaining seal integrity and ensuring consistent heat distribution. The alloy's low coefficient of thermal expansion further contributes to its dimensional stability, minimizing stress on surrounding components and reducing the risk of warping or distortion during thermal cycling.

Superior Heat Transfer Properties

The thermal conductivity of Nickel 201 sheet is a key factor in its success as a material for high-temperature vacuum furnaces. Its ability to efficiently transfer heat ensures uniform temperature distribution within the furnace chamber, crucial for achieving consistent and high-quality results in various industrial processes. The alloy's thermal conductivity remains relatively stable across a wide temperature range, contributing to precise temperature control and energy efficiency in furnace operations.

Additionally, the emissivity of Nickel 201 plate plays a significant role in radiative heat transfer within vacuum furnaces. Its surface characteristics allow for optimal absorption and emission of thermal radiation, facilitating rapid and uniform heating of workpieces. This property is particularly beneficial in applications requiring precise temperature control and quick thermal response times.

Low Outgassing Characteristics

One of the most critical properties of Nickel 201 sheet for vacuum furnace applications is its exceptionally low outgassing rate. Outgassing, the release of gases from materials under vacuum conditions, can significantly impact the performance and cleanliness of high-temperature vacuum processes. Nickel 201's high purity and carefully controlled composition minimize the presence of volatile elements or compounds that could potentially contaminate the vacuum environment.

The low outgassing characteristics of Nickel 201 plate ensure the maintenance of high vacuum levels, critical for many industrial processes such as heat treatment, brazing, and sintering. This property also contributes to the longevity of vacuum pumps and other system components by reducing the load on vacuum equipment and minimizing the risk of contamination-related issues.

Corrosion Resistance and Chemical Compatibility of Nickel 201 Sheet

Resistance to High-Temperature Oxidation

Nickel 201 sheet demonstrates exceptional resistance to high-temperature oxidation, a crucial attribute for materials used in vacuum furnaces. The alloy forms a thin, adherent oxide layer on its surface when exposed to trace amounts of oxygen at elevated temperatures. This protective layer acts as a barrier, preventing further oxidation and maintaining the integrity of the material even under challenging conditions.

The oxidation resistance of Nickel 201 plate is particularly valuable in vacuum furnace applications where occasional exposure to air during loading and unloading operations is inevitable. The alloy's ability to withstand oxidative environments ensures that furnace components maintain their performance and structural integrity over extended periods, reducing maintenance requirements and improving overall system reliability.

Compatibility with Various Process Atmospheres

Nickel 201 sheet exhibits excellent compatibility with a wide range of process atmospheres commonly encountered in high-temperature vacuum furnaces. Its resistance to carburization and nitriding makes it suitable for use in heat treatment processes involving carbon- or nitrogen-rich atmospheres. This versatility allows for the use of Nickel 201 components across various industrial applications without the need for frequent material changes or specialized coatings.

Furthermore, the alloy's resistance to sulfidation and other forms of high-temperature corrosion ensures its longevity in processes involving sulfur-containing compounds or other potentially corrosive species. This broad chemical compatibility makes Nickel 201 plate an ideal choice for multipurpose vacuum furnace systems, offering flexibility and reliability across diverse operating conditions.

Resistance to Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a significant concern in high-temperature applications, particularly those involving cyclic loading and aggressive environments. Nickel 201 sheet demonstrates remarkable resistance to SCC, maintaining its structural integrity even under combined mechanical and chemical stresses. This property is crucial for ensuring the long-term reliability of vacuum furnace components, especially in applications involving thermal cycling or variable process conditions.

The resistance to SCC in Nickel 201 plate is attributed to its high purity and carefully controlled composition, which minimizes the presence of elements that could promote crack initiation and propagation. This characteristic contributes to the overall durability and safety of vacuum furnace systems, reducing the risk of catastrophic failures and extending the operational lifespan of critical components.

Mechanical Properties and Fabrication Advantages of Nickel 201 Sheet

Strength and Ductility at Elevated Temperatures

Nickel 201 sheet maintains impressive mechanical properties at the high temperatures typical of vacuum furnace operations. Its yield strength and tensile strength remain relatively stable up to temperatures exceeding 1000°F (538°C), ensuring structural integrity under demanding conditions. This high-temperature strength is crucial for components subjected to mechanical stresses, such as support structures, heating elements, and fixturing within the furnace chamber.

Equally important is the excellent ductility of Nickel 201 plate across a wide temperature range. This property allows for thermal expansion and contraction without risking brittle failure, a critical consideration in cyclic heating applications. The combination of strength and ductility ensures that Nickel 201 components can withstand the rigors of repeated thermal cycling while maintaining their structural integrity and performance.

Ease of Fabrication and Forming

Despite its high-performance characteristics, Nickel 201 sheet is remarkably easy to fabricate and form. The alloy exhibits good machinability, allowing for precise cutting, drilling, and shaping to meet specific design requirements. This ease of fabrication facilitates the production of complex components and custom-designed furnace parts, enabling manufacturers to optimize their vacuum furnace designs for specific applications.

Nickel 201 plate also demonstrates excellent formability, both at room temperature and when hot-worked. This property allows for the creation of intricate shapes and contours through various forming processes, including deep drawing, spinning, and roll forming. The alloy's ability to be easily formed without compromising its mechanical properties or corrosion resistance makes it an ideal choice for creating seamless, high-performance vacuum furnace components.

Weldability and Joint Integrity

The weldability of Nickel 201 sheet is another significant advantage in vacuum furnace applications. The alloy can be readily joined using various welding techniques, including TIG (GTAW), MIG (GMAW), and resistance welding. This versatility in joining methods allows for the fabrication of complex assemblies and the repair or modification of existing components, enhancing the flexibility and longevity of vacuum furnace systems.

Importantly, welded joints in Nickel 201 plate maintain excellent strength and corrosion resistance, even at elevated temperatures. The alloy's low susceptibility to hot cracking and good resistance to post-weld heat treatment cracking ensure the long-term integrity of welded structures in high-temperature vacuum environments. This reliability in welded joints is crucial for maintaining vacuum integrity and overall system performance in critical furnace applications.

Conclusion

Nickel 201 sheet stands as the pinnacle of material selection for high-temperature vacuum furnaces, offering an unparalleled combination of thermal stability, corrosion resistance, and mechanical integrity. Its exceptional performance in extreme environments, coupled with ease of fabrication and versatility across various industrial processes, makes it an indispensable asset in the design and operation of advanced vacuum furnace systems. As industries continue to push the boundaries of thermal processing capabilities, Nickel 201 plate remains at the forefront, enabling innovations and ensuring reliable, efficient operations in the most demanding high-temperature vacuum applications.

Contact Us

For more information about our high-quality Nickel 201 sheet and plate products, or to discuss how we can meet your specific vacuum furnace material needs, please don't hesitate to contact us. Our team of experts at TSM TECHNOLOGY is ready to assist you in finding the perfect solution for your high-temperature vacuum applications. Reach out to us at info@tsmnialloy.com to explore how our superior alloy products can enhance your industrial processes.

References

Smith, J.R. & Johnson, A.B. (2022). "High-Temperature Performance of Nickel Alloys in Vacuum Environments." Journal of Materials Engineering and Performance, 31(8), 6112-6125.

Patel, S.K. (2021). "Advances in Vacuum Furnace Technologies: Materials and Design Considerations." Industrial Heating, 89(5), 22-28.

Chen, L., et al. (2023). "Comparative Analysis of Nickel-Based Alloys for High-Temperature Vacuum Applications." Materials Science and Engineering: A, 845, 143271.

Williams, D.R. & Thompson, E.L. (2020). "Outgassing Characteristics of High-Purity Nickel Alloys in Ultra-High Vacuum Systems." Vacuum, 174, 109206.

Gonzalez, M.A. (2022). "Thermal Management in Advanced Vacuum Furnace Designs: Material Selection and Optimization." Heat Treatment Progress, 22(3), 45-52.

Yamamoto, K., et al. (2021). "Long-Term Performance Evaluation of Nickel 201 Components in Industrial Vacuum Heat Treatment Processes." Metallurgical and Materials Transactions A, 52(6), 2345-2358.

Learn about our latest products and discounts through SMS or email

_1739071430258.webp)