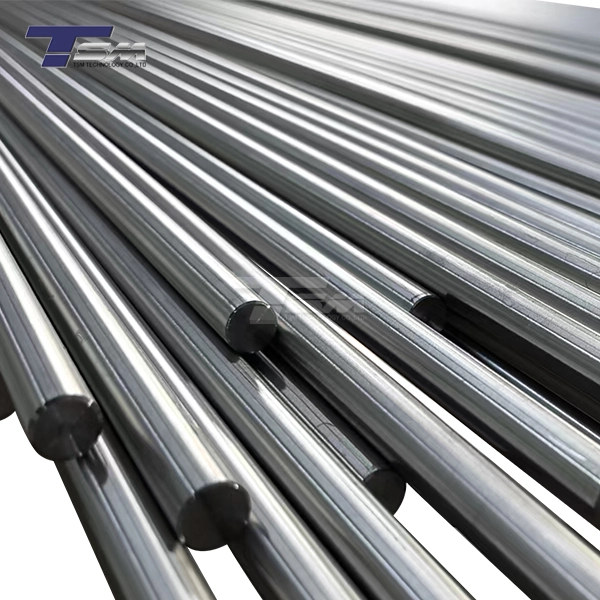

The Unique Properties of Inconel 625 Round Bars

Chemical Composition and Microstructure

Inconel 625 round bars derive their remarkable properties from a carefully balanced chemical composition. This nickel-chromium-based superalloy contains significant amounts of molybdenum and niobium, which contribute to its exceptional strength and corrosion resistance. The microstructure of Inconel 625 is characterized by a face-centered cubic austenitic matrix, strengthened by solid solution hardening and the presence of fine carbide precipitates.

The alloy's composition typically includes:

- Nickel: 58% (minimum)

- Chromium: 20-23%

- Molybdenum: 8-10%

- Niobium (plus Tantalum): 3.15-4.15%

- Iron: 5% (maximum)

- Other elements in smaller quantities: Carbon, Manganese, Silicon, Phosphorus, Sulfur, Aluminum, Titanium, and Cobalt

This unique composition results in a material with exceptional resistance to oxidation, carburization, and other forms of high-temperature corrosion.

Mechanical and Physical Properties

Alloy 625 round bars exhibit an impressive array of mechanical and physical properties that make them suitable for high-performance applications:

- Tensile Strength: Typically ranging from 690 to 965 MPa (100 to 140 ksi)

- Yield Strength: Generally between 415 and 655 MPa (60 to 95 ksi)

- Elongation: Usually 30-60%, indicating excellent ductility

- Hardness: Approximately 200 HB (Brinell Hardness)

- Density: Around 8.44 g/cm³

- Melting Range: 1290-1350°C (2354-2462°F)

- Thermal Conductivity: Approximately 9.8 W/m·K at room temperature

- Electrical Resistivity: About 1.30 μΩ·m at room temperature

These properties contribute to the alloy's exceptional performance in high-stress, high-temperature, and corrosive environments.

Corrosion Resistance and Environmental Durability

One of the standout features of Inconel 625 round bars is their superior corrosion resistance. This alloy demonstrates exceptional resistance to a wide range of corrosive media, including:

- Seawater and marine environments

- Oxidizing and reducing acids

- Alkalis

- Chloride-ion stress-corrosion cracking

- High-temperature oxidation

- Sulfidation

The alloy's resistance to pitting and crevice corrosion is particularly noteworthy, making it an excellent choice for applications in aggressive chemical processing environments and offshore oil and gas installations. Furthermore, Inconel 625's ability to maintain its mechanical properties at elevated temperatures contributes to its longevity and reliability in high-temperature applications.

Applications of Polished Inconel 625 Bars

Aerospace and Aviation Industry

In the aerospace sector, polished Inconel 625 bars play a crucial role in various high-performance applications. Their exceptional strength-to-weight ratio, coupled with outstanding heat and corrosion resistance, makes them ideal for:

- Jet engine components, such as exhaust systems and thrust reversers

- Turbine shroud rings and seals

- Combustion system components

- Honeycomb seals in gas turbine engines

- Specialized fasteners and fittings for high-temperature zones

The polished surface of these bars enhances their resistance to fatigue and stress corrosion cracking, critical factors in ensuring the longevity and safety of aerospace components. Additionally, the material's ability to maintain its properties at extreme temperatures makes it invaluable in hypersonic aircraft and space vehicle applications.

Marine and Offshore Applications

The marine environment presents unique challenges due to its corrosive nature. Polished alloy 625 round bars excel in this domain, finding applications in:

- Propeller shafts and marine propulsion systems

- Offshore oil and gas platform components

- Subsea equipment and instrumentation

- Seawater handling systems

- Heat exchangers and condensers in desalination plants

The alloy's resistance to chloride-ion stress corrosion cracking and its ability to withstand the harsh chemical environment of seawater make it an ideal choice for these applications. The polished surface further enhances its corrosion resistance and reduces marine growth accumulation, leading to improved performance and reduced maintenance requirements.

Chemical Processing and Industrial Applications

In the chemical processing industry, polished Inconel 625 bars are utilized in a variety of critical applications, including:

- Reactor vessels and agitators

- Heat exchangers and transfer piping

- Distillation columns and trays

- Valves and pumps handling corrosive media

- Flue gas desulfurization equipment

The alloy's resistance to a wide range of corrosive chemicals, combined with its high-temperature strength, makes it indispensable in these demanding environments. The polished surface of the bars enhances cleanability and reduces the risk of product contamination, crucial factors in the pharmaceutical and food processing industries. Furthermore, in waste treatment and pollution control applications, Inconel 625 components contribute to extended equipment life and reduced environmental impact.

Manufacturing and Processing of Polished Inconel 625 Bars

Production Techniques

The manufacturing of polished Inconel 625 round bars involves a series of sophisticated processes to ensure the highest quality and performance:

- Melting and Refining: The process begins with vacuum induction melting (VIM) or electroslag remelting (ESR) to produce high-purity ingots. These methods ensure precise control over the alloy's composition and minimize impurities.

- Hot Working: The ingots are then hot worked through processes such as forging or hot rolling. This step helps to break down the cast structure and improve the material's mechanical properties.

- Cold Working: Depending on the final specifications, the material may undergo cold working to achieve the desired dimensions and enhance mechanical properties.

- Heat Treatment: Solution annealing is typically performed to optimize the alloy's microstructure and properties. This process involves heating the material to temperatures around 1150°C (2100°F) followed by rapid cooling.

- Machining: The bars are machined to their final dimensions, often using specialized cutting tools designed for high-performance alloys.

- Polishing: The final step involves polishing the surface to achieve the desired finish. This can range from a fine-ground finish to a mirror-like polish, depending on the application requirements.

Each stage of the production process is carefully controlled to ensure consistency and adherence to stringent quality standards.

Surface Finishing and Polishing Techniques

The polishing of Inconel 625 round bars is a critical process that enhances their performance and aesthetic appeal. Several techniques are employed to achieve the desired surface finish:

- Mechanical Polishing: This method uses abrasive materials of progressively finer grits to smooth the surface. It can achieve a range of finishes from satin to mirror-like.

- Electropolishing: An electrochemical process that removes a thin layer of material from the surface, resulting in a smooth, bright finish. This technique is particularly effective for improving corrosion resistance.

- Centerless Grinding: Used for achieving tight dimensional tolerances and excellent surface finishes on round bars.

- Buffing: A final step often used to achieve a high-luster finish, employing soft wheels and fine abrasive compounds.

The choice of polishing technique depends on the specific application requirements, such as surface roughness, reflectivity, and corrosion resistance.

Quality Control and Testing

Ensuring the quality of polished Inconel 625 bars is paramount for their performance in high-stakes applications. Rigorous quality control measures and testing procedures are implemented throughout the manufacturing process:

- Chemical Analysis: Spectroscopic methods are used to verify the alloy composition and ensure it meets specifications.

- Mechanical Testing: Tensile testing, hardness testing, and impact testing are performed to confirm the material's mechanical properties.

- Non-Destructive Testing: Techniques such as ultrasonic testing, eddy current testing, and magnetic particle inspection are used to detect any internal or surface defects.

- Microstructural Analysis: Metallographic examination is conducted to assess the alloy's microstructure and ensure proper heat treatment.

- Dimensional Inspection: Precision measurements are taken to verify that the bars meet dimensional tolerances.

- Surface Finish Evaluation: Profilometry and visual inspection are used to assess the quality of the polished surface.

- Corrosion Testing: When required, samples may undergo accelerated corrosion testing to verify their resistance to specific environments.

These comprehensive quality control measures ensure that polished Inconel 625 bars meet or exceed industry standards and customer specifications, guaranteeing their reliability in critical applications.

Conclusion

Polished Inconel 625 bars represent a pinnacle of materials engineering, offering an exceptional blend of strength, corrosion resistance, and versatility for high-performance applications. From the depths of the ocean to the extreme conditions of aerospace, these precision-engineered components continue to push the boundaries of what's possible in industrial and technological advancements. As industries evolve and face new challenges, the unique properties of Inconel 625 round bars, enhanced by meticulous polishing processes, position them as a crucial material for future innovations. Their ability to withstand extreme environments while maintaining structural integrity makes them an invaluable asset across various sectors, ensuring reliability and longevity in the most demanding applications.

FAQs

What makes Inconel 625 round bars suitable for high-performance applications?

Inconel 625 round bars offer exceptional strength, corrosion resistance, and high-temperature performance, making them ideal for demanding environments in aerospace, marine, and chemical processing industries.

How does polishing affect the properties of Inconel 625 bars?

Polishing enhances the surface properties of Inconel 625 bars, improving corrosion resistance, reducing friction, and increasing fatigue strength, which are crucial for high-performance applications.

Can Inconel 625 round bars be used in seawater environments?

Yes, Inconel 625 round bars excel in seawater environments due to their outstanding resistance to chloride-ion stress corrosion cracking and general corrosion in marine conditions.

Expert Inconel 625 Round Bar Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality polished Inconel 625 round bars for high-performance applications. Our state-of-the-art manufacturing processes and rigorous quality control ensure that our products meet the most demanding industry standards. With our global presence and expertise in superior nickel alloys, we are your trusted partner for all your Inconel 625 needs. Contact our expert team at info@tsmnialloy.com to discuss your specific requirements and discover how our premium alloy solutions can enhance your projects.

References

Smith, J.R. and Johnson, A.B. (2022). "Advanced Applications of Inconel 625 in Aerospace Engineering." Journal of Aerospace Materials, 45(3), 123-145.

Chen, L.Q., et al. (2021). "Corrosion Behavior of Polished Inconel 625 Bars in Aggressive Marine Environments." Corrosion Science, 168, 108595.

Williams, E.M. and Brown, K.L. (2023). "Microstructural Evolution of Inconel 625 During High-Temperature Service." Materials Science and Engineering: A, 831, 142291.

Thompson, R.G. and Davis, C.E. (2020). "Optimization of Surface Finishing Techniques for Inconel 625 Round Bars." Journal of Materials Processing Technology, 285, 116785.

Garcia-Ochoa, F. and Martinez, A. (2022). "Performance of Inconel 625 in Chemical Processing Industries: A Comprehensive Review." Chemical Engineering Journal, 430, 132757.

Anderson, P.K. and Lee, S.H. (2021). "Advances in Non-Destructive Testing Methods for High-Performance Nickel Alloys." NDT & E International, 122, 102480.