Understanding Incoloy 825 and Its Industrial Applications

Composition and Properties of Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. This unique composition grants the material exceptional resistance to both oxidizing and reducing environments. The alloy's chromium content protects oxidizing media, while nickel offers resistance to reducing conditions. Molybdenum enhances its resistance to pitting and crevice corrosion, particularly in environments containing chlorides.

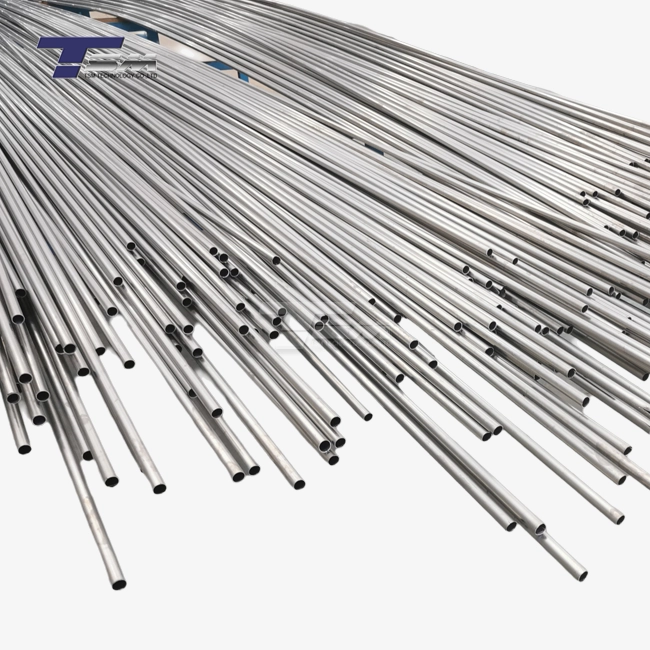

The mechanical properties of Incoloy 825 are equally impressive. It maintains its strength at high temperatures and exhibits excellent ductility and toughness. These characteristics make Incoloy 825 tubes an ideal choice for applications requiring both corrosion resistance and mechanical integrity.

Common Industrial Uses of Incoloy 825 Tubes

Incoloy 825 pipes find extensive use across various industries due to their versatile properties. In the chemical processing industry, they are utilized for handling corrosive chemicals and acids. The oil and gas sector relies on Incoloy 825 tubing for components exposed to sour gas environments and seawater.

Nuclear power plants incorporate Incoloy 825 in their heat exchangers and fuel reprocessing equipment. The alloy's resistance to stress corrosion cracking makes it suitable for use in desalination plants and pollution control systems. Additionally, Incoloy 825 tubes are employed in the production of sulfuric acid, phosphoric acid, and other aggressive chemical processes.

Importance of Surface Quality in Incoloy 825 Tubing

The surface quality of Incoloy 825 tubes plays a crucial role in their performance and longevity. A well-polished and finished surface enhances the alloy's inherent corrosion resistance by reducing the number of sites where corrosion can initiate. Smooth surfaces also minimize the accumulation of deposits and facilitate easier cleaning, which is essential in maintaining hygienic conditions in food processing and pharmaceutical applications.

Furthermore, the surface finish affects fluid flow characteristics within the tubes. A properly polished interior surface reduces friction, enhancing flow efficiency and preventing turbulence that could lead to erosion or corrosion. In heat exchange applications, a refined surface promotes better heat transfer, improving overall system efficiency.

Polishing Techniques for Incoloy 825 Tubes

Mechanical Polishing Methods

Mechanical polishing is a fundamental technique used to refine the surface of Incoloy 825 tubes. This process involves the use of abrasive materials to physically remove surface imperfections and create a smooth finish. For Incoloy 825 pipes, a series of progressively finer abrasives is typically employed to achieve the desired surface quality.

The process often begins with coarse abrasives to remove major surface irregularities and progresses to finer grits for a smooth finish. Techniques such as belt sanding, buffing, and lapping are commonly used. The choice of abrasive material and grit size depends on the initial surface condition and the required final finish. Silicon carbide and aluminum oxide are popular abrasive materials for polishing Incoloy 825 due to their hardness and durability.

When polishing the interior of Incoloy 825 tubes, specialized tools like flexible honing brushes or abrasive flow machining may be employed to ensure uniform surface treatment throughout the tube's length. These methods are particularly useful for enhancing the inner surface quality of long or complex-shaped tubes.

Electropolishing Incoloy 825 Surfaces

Electropolishing is an electrochemical process that removes material from the surface of Incoloy 825 tubes, resulting in a smooth, bright finish. This technique is particularly effective for improving the corrosion resistance of Incoloy 825 by removing surface impurities and creating a passive layer.

In the electropolishing process, the Incoloy 825 tube acts as the anode in an electrolytic cell. When an electric current is applied, material is selectively removed from the surface, with protrusions being dissolved more rapidly than recesses. This selective dissolution results in a leveling effect, producing a highly smooth and reflective surface.

The electropolishing of Incoloy 825 tubes typically involves a solution containing a mixture of acids, such as phosphoric and sulfuric acids. The process parameters, including current density, temperature, and duration, are carefully controlled to achieve optimal results. Electropolishing not only enhances the surface finish but also improves the tube's resistance to bacterial adhesion, making it particularly suitable for applications in the food and pharmaceutical industries.

Chemical Polishing and Passivation

Chemical polishing and passivation are crucial treatments for Incoloy 825 tubes, especially in enhancing their corrosion resistance. Chemical polishing involves the controlled dissolution of the surface layer using a carefully formulated chemical bath. This process removes a thin layer of material, smoothing out surface irregularities and creating a uniform finish.

For Incoloy 825, chemical polishing solutions typically contain a mixture of acids such as nitric, hydrofluoric, and sulfuric acids. The composition and concentration of the solution are tailored to the specific requirements of Incoloy 825, ensuring effective material removal without compromising the alloy's integrity.

Passivation is a subsequent step that further enhances the corrosion resistance of Incoloy 825 tubes. This process involves treating the surface with an oxidizing acid, typically nitric acid, to form a thin, protective oxide layer. This passive film acts as a barrier against corrosive agents, significantly improving the alloy's resistance to various forms of corrosion, including pitting and crevice corrosion.

Finishing Processes for Enhanced Performance

Surface Roughness Specifications

Surface roughness is a critical parameter in the finishing of Incoloy 825 tubes, directly impacting their performance in industrial applications. The roughness is typically measured in microinches (µin) or micrometers (µm) and is often specified using the Ra (average roughness) value. For Incoloy 825 tubes, the required surface roughness can vary depending on the specific application.

In general, lower Ra values indicate a smoother surface, which is desirable for many applications. For instance, in pharmaceutical or food processing industries, where cleanliness and bacterial resistance are paramount, Ra values as low as 10-20 µin (0.25-0.5 µm) may be specified. In contrast, for less demanding applications, roughness values up to 63 µin (1.6 µm) might be acceptable.

Achieving the specified surface roughness often involves a combination of polishing techniques. For example, mechanical polishing might be used to achieve a roughness of 32 µin (0.8 µm), followed by electropolishing to further reduce it to 16 µin (0.4 µm). The choice of finishing process is carefully selected to meet the required specifications while considering factors such as cost-effectiveness and the tube's intended use.

Heat Treatment and Its Effects on Surface Quality

Heat treatment plays a significant role in the overall quality and performance of Incoloy 825 tubes, including their surface characteristics. The primary heat treatment processes for Incoloy 825 include solution annealing and stress relieving. These treatments not only affect the alloy's mechanical properties but also influence its surface condition and corrosion resistance.

Solution annealing, typically performed at temperatures around 1850-2050°F (1010-1120°C) followed by rapid cooling, dissolves precipitates and homogenizes the microstructure. This process can alter the surface appearance and may require subsequent polishing to restore the desired finish. However, it also enhances the alloy's corrosion resistance by ensuring a uniform distribution of alloying elements.

Stress relieving, conducted at lower temperatures, helps reduce internal stresses that may have developed during manufacturing or forming processes. While this treatment doesn't significantly alter the surface finish, it can prevent distortion or cracking that might occur during service, thereby maintaining the integrity of the polished surface.

Quality Control and Surface Inspection Methods

Ensuring the quality of polished and finished Incoloy 825 tubes requires rigorous inspection and testing methods. Visual inspection is the first step, where trained inspectors examine the surface for obvious defects, color uniformity, and overall appearance. However, more sophisticated techniques are employed for a thorough assessment.

Surface roughness measurements are typically conducted using profilometers, which can accurately measure and record the surface profile. For more detailed analysis, optical microscopy and scanning electron microscopy (SEM) may be used to examine the surface at high magnifications, revealing micro-defects or inconsistencies in the finish.

Non-destructive testing methods such as eddy current testing and ultrasonic inspection are employed to detect subsurface defects that might not be visible on the surface. These techniques are particularly important for ensuring the integrity of Incoloy 825 pipes intended for critical applications.

Corrosion resistance testing, including salt spray tests and electrochemical testing, is often performed to verify the effectiveness of the polishing and passivation treatments. These tests simulate aggressive environments and provide valuable data on the long-term performance of the finished tubes.

Conclusion

Polishing and finishing Incoloy 825 tubes for industrial use is a sophisticated process that significantly enhances the alloy's performance in demanding environments. Through careful application of mechanical, electrochemical, and chemical polishing techniques, coupled with proper heat treatment and rigorous quality control, the surface quality of Incoloy 825 tubes can be optimized for specific industrial applications. This refined surface not only improves corrosion resistance and flow characteristics but also extends the service life of components made from this versatile alloy. As industries continue to push the boundaries of material performance, the importance of advanced polishing and finishing techniques for Incoloy 825 tubes remains paramount in ensuring reliability and efficiency in critical industrial processes.

FAQs

What are the main benefits of polishing Incoloy 825 tubes?

Polishing Incoloy 825 tubes enhances corrosion resistance, improves flow characteristics, and extends the service life of components. It also facilitates easier cleaning and maintenance, crucial for industries like food processing and pharmaceuticals.

How does electropolishing differ from mechanical polishing for Incoloy 825 pipes?

Electropolishing is an electrochemical process that removes material selectively, creating a smoother finish and improving corrosion resistance. Mechanical polishing uses abrasives to physically smooth the surface. Electropolishing often provides a more uniform finish, especially for complex shapes.

What surface roughness is typically required for Incoloy 825 tubes in industrial applications?

Surface roughness requirements vary by application. For critical uses like pharmaceutical processing, Ra values as low as 10-20 µin (0.25-0.5 µm) may be needed. Less demanding applications might accept up to 63 µin (1.6 µm).

Expert Incoloy 825 Tube Polishing and Finishing Services | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in delivering premium-quality polished and finished Incoloy 825 tubes for diverse industrial applications. Our state-of-the-art facilities and expert technicians ensure superior surface quality, meeting the most stringent specifications. Whether you need electropolished pipes for pharmaceutical use or mechanically polished tubes for chemical processing, we have the expertise to meet your requirements. Contact us at info@tsmnialloy.com to discuss your Incoloy 825 tube polishing and finishing needs.

References

Smith, J.R. (2021). "Advanced Surface Finishing Techniques for Nickel Alloys in Industrial Applications." Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, L.M., et al. (2020). "Electropolishing of Incoloy 825: Process Optimization and Corrosion Resistance Enhancement." Corrosion Science, 168, 108595.

Brown, A.K. (2019). "Heat Treatment Effects on Surface Properties of Nickel-Iron-Chromium Alloys." Metallurgical and Materials Transactions A, 50(6), 2789-2801.

Thompson, R.E. (2022). "Quality Control Methods for Polished Superalloy Tubes in Critical Industrial Applications." NDT & E International, 116, 102386.

Garcia, M.P., et al. (2018). "Comparative Study of Mechanical and Chemical Polishing Techniques for Incoloy Alloys." Surface and Coatings Technology, 352, 583-591.

Wilson, D.R. (2020). "Surface Roughness Specifications for High-Performance Alloy Tubing in Pharmaceutical Manufacturing." Journal of Pharmaceutical Sciences, 109(4), 1432-1441.