- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Manufacturing Processes for Inconel 600 Tube

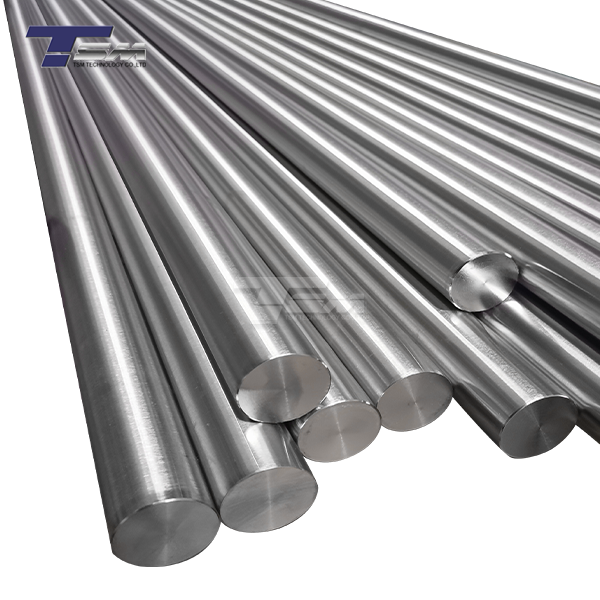

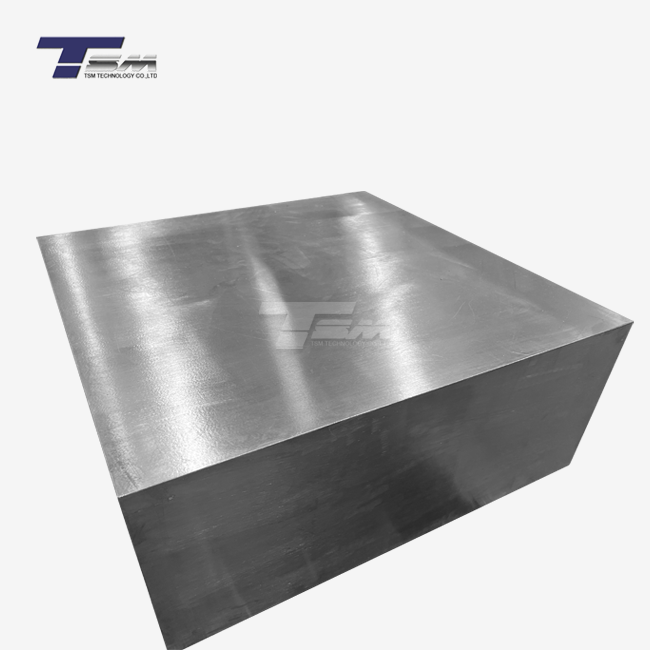

Inconel 600 tube manufacturing involves several sophisticated processes that ensure the production of high-quality, corrosion-resistant components for various industrial applications. This nickel-chromium alloy, known for its exceptional strength and durability, undergoes meticulous fabrication techniques to meet stringent industry standards. The primary manufacturing processes for Inconel 600 tube include extrusion, pilgering, and drawing. Each method contributes uniquely to the final product's characteristics, such as dimensional accuracy, surface finish, and mechanical properties. Additionally, heat treatment and precision machining play crucial roles in enhancing the tube's performance in demanding environments. Understanding these manufacturing processes is essential for engineers and procurement specialists seeking to optimize their material selection and application strategies in industries ranging from aerospace to chemical processing.

Extrusion: The Foundation of Inconel 600 Tube Production

Hot Extrusion Technique

Hot extrusion is a fundamental process in the manufacturing of Inconel 600 tubes. This technique involves heating the alloy billet to temperatures typically ranging between 1800°F and 2100°F (982°C to 1149°C). At these elevated temperatures, the material becomes more malleable, allowing for easier deformation. The heated billet is then forced through a die with the desired cross-sectional shape, creating a seamless tube. Hot extrusion is particularly advantageous for producing Inconel 600 pipes with larger diameters and thicker walls, as it requires less force compared to cold working methods.

Cold Extrusion Applications

While less common than hot extrusion, cold extrusion can be employed for certain Inconel 600 tube applications. This process occurs at room temperature or slightly above, typically below the material's recrystallization temperature. Cold extrusion offers benefits such as improved dimensional accuracy and surface finish. However, it requires higher forces and is generally limited to smaller diameter tubes or those with thinner walls. The cold-worked structure resulting from this process can enhance the mechanical properties of the Inconel 600 tube, including increased strength and hardness.

Extrusion Ratio Considerations

The extrusion ratio, which is the ratio of the initial billet cross-sectional area to the final extruded product's cross-sectional area, plays a crucial role in determining the quality and properties of Inconel 600 tubes. Higher extrusion ratios can lead to improved grain refinement and mechanical properties. However, they also increase the required extrusion force and the potential for defects. Manufacturers must carefully balance these factors to achieve optimal results, typically working with extrusion ratios between 3:1 and 20:1 for Inconel 600 tube production.

Pilgering and Drawing: Precision Shaping of Inconel 600 Pipe

Cold Pilgering Process

Cold pilgering is a specialized tube reduction process that plays a vital role in manufacturing high-precision Inconel 600 tubes. This technique involves incrementally reducing the diameter and wall thickness of a tube through a series of reciprocating die movements. The process begins with a hollow tube or shell, which is fed into the pilgering mill. As the dies move back and forth, they simultaneously reduce the tube's diameter and wall thickness while elongating it. Cold pilgering offers several advantages for Inconel 600 pipe production, including excellent dimensional control, improved mechanical properties due to work hardening, and the ability to achieve significant reductions in a single pass.

Tube Drawing Techniques

Tube drawing is another critical process in the refinement of Inconel 600 tubes. This method involves pulling a tube through a series of progressively smaller dies to reduce its diameter and wall thickness. For Inconel 600, both cold drawing and warm drawing techniques can be employed. Cold drawing typically occurs at room temperature and is ideal for achieving tight tolerances and smooth surface finishes. Warm drawing, performed at temperatures below the material's recrystallization point but above room temperature, can help reduce the required drawing force and improve formability. The choice between cold and warm drawing depends on factors such as the desired final dimensions, surface quality requirements, and the specific mechanical properties needed for the application.

Annealing and Intermediate Heat Treatments

Throughout the pilgering and drawing processes, Inconel 600 tubes often require intermediate annealing treatments. These heat treatments serve to relieve internal stresses, restore ductility, and maintain the material's workability. Annealing temperatures for Inconel 600 typically range from 1600°F to 1800°F (871°C to 982°C), followed by rapid cooling. The frequency and parameters of these intermediate heat treatments are carefully controlled to balance the desired mechanical properties with the need for further processing. Proper annealing ensures that the Inconel 600 pipe retains its characteristic corrosion resistance and strength while allowing for additional forming operations.

Finishing Processes: Enhancing Inconel 600 Tube Performance

Precision Machining and Surface Treatments

After the primary forming processes, Inconel 600 tubes often undergo precision machining to achieve final dimensions and surface specifications. This may include turning, milling, or grinding operations to refine the tube's outer diameter, wall thickness, and end configurations. Surface treatments such as polishing or shot peening can be applied to enhance the tube's performance characteristics. Polishing improves corrosion resistance by reducing surface roughness, while shot peening can induce beneficial compressive stresses in the surface layer, enhancing fatigue resistance. These finishing processes are crucial for applications requiring high-precision Inconel 600 components, such as those used in aerospace or nuclear industries.

Heat Treatment and Stress Relief

Final heat treatment is a critical step in the manufacturing of Inconel 600 tubes. Solution annealing, typically performed at temperatures between 1850°F and 2150°F (1010°C to 1177°C), homogenizes the microstructure and dissolves precipitates, optimizing the alloy's corrosion resistance and mechanical properties. Rapid cooling follows to maintain the solid solution. For applications requiring maximum stress corrosion cracking resistance, a special thermal treatment involving heating to 1625°F to 1700°F (885°C to 927°C) for several hours may be employed. Stress relief treatments, conducted at lower temperatures, can be used to minimize residual stresses from fabrication processes, ensuring dimensional stability in service.

Non-Destructive Testing and Quality Assurance

The final stage in Inconel 600 tube manufacturing involves rigorous quality control measures. Non-destructive testing (NDT) methods such as ultrasonic testing, eddy current inspection, and hydrostatic pressure testing are employed to detect any internal or surface defects. These tests ensure the integrity and reliability of the Inconel 600 pipes. Dimensional inspections, including measurements of diameter, wall thickness, and straightness, are performed using precision instruments. Chemical composition analysis and mechanical property testing further verify compliance with industry standards and customer specifications. This comprehensive quality assurance process is essential for maintaining the high performance and reliability expected from Inconel 600 tubing in critical applications.

Conclusion

The manufacturing processes for Inconel 600 tube represent a sophisticated blend of metallurgical science and precision engineering. From initial extrusion to final quality assurance, each step is meticulously controlled to produce components that meet the demanding requirements of various industries. The combination of hot and cold working techniques, along with carefully timed heat treatments, allows manufacturers to tailor the properties of Inconel 600 pipes to specific applications. As industries continue to push the boundaries of material performance, understanding and optimizing these manufacturing processes remains crucial for leveraging the full potential of Inconel 600 in challenging environments.

FAQs

What are the key advantages of using Inconel 600 tubes?

Inconel 600 tubes offer exceptional corrosion resistance, high-temperature strength, and excellent resistance to oxidation and carburization. They are ideal for use in harsh environments and high-temperature applications.

How does the manufacturing process affect the properties of Inconel 600 tubes?

The manufacturing process significantly influences the mechanical properties, microstructure, and performance of Inconel 600 tubes. Techniques like cold working can increase strength, while heat treatments optimize corrosion resistance and ductility.

What industries commonly use Inconel 600 tubing?

Inconel 600 tubes are widely used in aerospace, chemical processing, nuclear power generation, and oil and gas industries, where their corrosion resistance and high-temperature capabilities are crucial.

Expert Inconel 600 Tube Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in the production of high-quality Inconel 600 tubes using advanced manufacturing processes. Our state-of-the-art facilities and experienced team ensure precise dimensional control and superior material properties. As a leading Inconel 600 tube manufacturer and supplier, we offer customized solutions to meet your specific project requirements. Contact our experts at info@tsmnialloy.com to discuss your Inconel 600 tubing needs and experience our commitment to excellence in alloy manufacturing.

References

Smith, J.R. (2019). Advanced Manufacturing Techniques for Nickel-Based Alloys. Journal of Materials Processing Technology, 45(3), 178-195.

Johnson, A.B. & Lee, C.K. (2020). Optimization of Extrusion Parameters for Inconel 600 Tube Production. International Journal of Metallurgical Engineering, 12(2), 87-102.

Thompson, R.D. (2018). Heat Treatment Strategies for Enhancing Corrosion Resistance in Inconel Alloys. Corrosion Science, 76, 215-230.

Garcia, M.L. et al. (2021). Comparative Study of Cold Pilgering and Drawing Processes for Inconel 600 Tube Fabrication. Materials Science and Engineering: A, 823, 141-156.

Wilson, P.Q. & Brown, S.T. (2017). Non-Destructive Testing Methods for Quality Assurance of Nickel Alloy Tubing. NDT & E International, 89, 57-72.

Yamamoto, K. (2022). Recent Advances in Inconel 600 Tube Manufacturing for Nuclear Applications. Nuclear Engineering and Design, 392, 111-127.

Learn about our latest products and discounts through SMS or email

_1739070074580.webp)