- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Recommended Welding Procedures and Filler Metals for Monel 400

Welding Monel 400 tubes, pipes, and other components requires careful attention to detail and proper techniques. For optimal results, use gas tungsten arc welding (GTAW) or shielded metal arc welding (SMAW) with matching filler metals such as ERNiCu-7 or ENiCu-7. Maintain a clean work environment, preheat to 150-200°F (65-93°C), and use low heat input to minimize distortion. Post-weld heat treatment is generally unnecessary. Proper gas shielding with argon or helium is crucial for high-quality welds. Always follow manufacturer guidelines and industry standards for best practices in welding Monel 400 materials.

Understanding Monel 400 Properties for Welding

Composition and Characteristics

Monel 400 is a nickel-copper alloy renowned for its exceptional corrosion resistance and strength. Comprising approximately 67% nickel and 31% copper, with small amounts of iron and manganese, this alloy offers unique welding challenges and opportunities. Its high nickel content contributes to excellent weldability, while the copper component enhances its resistance to seawater and various chemicals.

Thermal Conductivity and Heat Management

One crucial aspect of welding Monel 400 tubing is understanding its thermal properties. The alloy has a higher thermal conductivity than many stainless steels, which means heat dissipates quickly during welding. This characteristic necessitates careful heat input control to ensure proper fusion without overheating or distorting the material. Welders must be aware of this property when setting up their equipment and planning their welding sequence.

Oxidation Resistance and Surface Preparation

Monel 400 pipes exhibit excellent oxidation resistance, forming a protective oxide layer when exposed to air. However, this property can be both an advantage and a challenge in welding. While it helps protect the material during high-temperature operations, it also requires thorough surface preparation before welding. Proper cleaning and removal of any existing oxide layers are essential for achieving high-quality, defect-free welds in Monel 400 components.

Selecting the Right Welding Process for Monel 400

Gas Tungsten Arc Welding (GTAW)

GTAW, also known as TIG welding, is often the preferred method for welding Monel 400 tubes and pipes. This process offers precise control over heat input and produces high-quality, clean welds. When using GTAW for Monel 400, it's crucial to maintain a short arc length and use pure argon or helium as shielding gas. The ability to add filler metal separately allows for better control of the weld pool composition, making it ideal for thin-walled Monel tubing and intricate joints.

Shielded Metal Arc Welding (SMAW)

SMAW, or stick welding, is another viable option for welding Monel 400, particularly for thicker sections or field repairs. This method is more forgiving in terms of surface preparation and can be used in various positions. When employing SMAW for Monel 400 pipe welding, select electrodes specifically designed for nickel-copper alloys to ensure proper weld chemistry and mechanical properties. Proper electrode storage and handling are crucial to prevent moisture absorption and potential weld defects.

Other Welding Processes

While GTAW and SMAW are the most common methods, other processes can be used for Monel 400 welding under specific circumstances. Gas Metal Arc Welding (GMAW) can be employed for larger components or when higher deposition rates are needed. Plasma Arc Welding (PAW) offers advantages for automated welding of thin Monel 400 sheets or tubes. Each process has its pros and cons, and the choice depends on factors such as material thickness, joint design, and production requirements.

Filler Metal Selection and Welding Parameters

Matching Filler Metals

Selecting the appropriate filler metal is crucial for successful Monel 400 welding. The most common filler metals for Monel 400 tubing and pipes are ERNiCu-7 for GTAW and ENiCu-7 for SMAW. These filler metals closely match the composition of Monel 400, ensuring weld properties similar to the base material. In some cases, overmatching filler metals with higher nickel content may be used to enhance corrosion resistance or mechanical properties. Always consult material specifications and welding codes to determine the most suitable filler metal for your application.

Welding Parameters and Heat Input Control

Proper welding parameters are essential for achieving high-quality welds in Monel 400 components. When welding Monel 400 pipes or tubes, maintain a low heat input to minimize distortion and prevent hot cracking. For GTAW, use direct current electrode negative (DCEN) with amperages ranging from 50-150A, depending on material thickness. Travel speeds should be moderate to allow for proper fusion without excessive heat buildup. Pulsed welding techniques can be beneficial for controlling heat input and improving weld quality, especially on thin-walled Monel tubing.

Shielding Gas Considerations

Proper shielding gas selection and flow rates are critical for protecting the weld pool and preventing oxidation in Monel 400 welding. For GTAW, pure argon is the most common choice, offering good arc stability and weld appearance. Helium or argon-helium mixtures can be used for increased penetration on thicker sections. Gas flow rates typically range from 15-25 CFH (7-12 L/min) for most Monel 400 tube and pipe welding applications. Ensure adequate back purging for full penetration welds to protect the root side from oxidation.

Conclusion

Mastering the welding of Monel 400 tubes and pipes requires a thorough understanding of the material's properties, careful selection of welding processes and filler metals, and precise control of welding parameters. By following the recommended procedures outlined in this guide, welders can achieve high-quality, durable welds in Monel 400 components. Remember to always prioritize proper preparation, maintain cleanliness, and adhere to industry standards and specifications. With practice and attention to detail, welding Monel 400 can be a rewarding process, producing joints that withstand the most demanding corrosive environments and applications.

FAQs

What is the optimal preheat temperature for welding Monel 400 tubes?

Preheating to 150-200°F (65-93°C) is generally recommended for Monel 400 welding.

Can Monel 400 be welded to other materials?

Yes, Monel 400 can be welded to other nickel alloys, stainless steels, and some carbon steels using appropriate filler metals and procedures.

Is post-weld heat treatment necessary for Monel 400 welds?

Post-weld heat treatment is typically not required for Monel 400, but it may be beneficial in certain applications to relieve residual stresses.

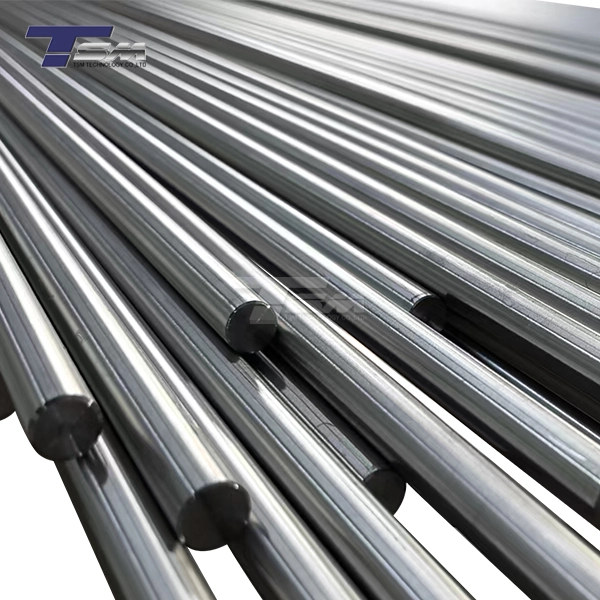

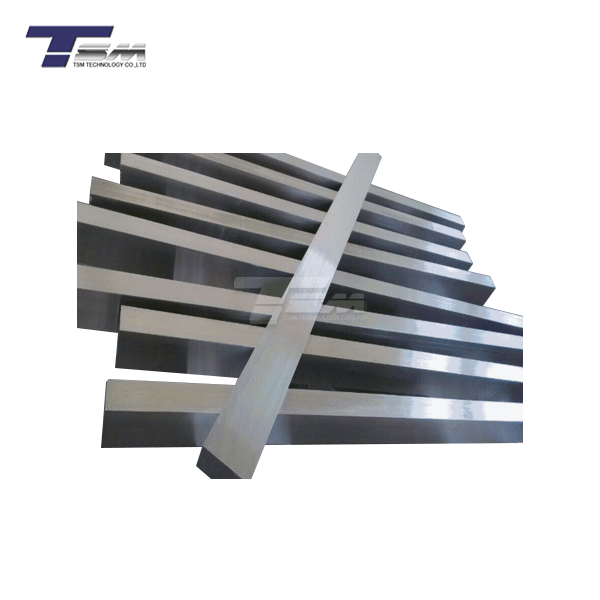

High-Quality Monel 400 Tubes for Industrial Applications | TSM TECHNOLOGY

At TSM Technology, we are a reliable Monel 400 tube manufacturer and supplier, dedicated to providing premium-quality tubes that meet demanding industrial requirements. Our advanced production facilities and strict quality control guarantee excellent corrosion resistance, durability, and performance in every Monel 400 tube. With a wide range of sizes and customization options available, we serve industries such as marine engineering, chemical processing, and oil & gas. For high-quality Monel 400 tubes tailored to your needs, contact us at info@tsmnialloy.com.

References

Smith, J. D. (2019). Welding Metallurgy of Nickel Alloys. Welding Journal, 98(5), 45-52.

Johnson, R. K. (2020). Advanced Techniques for Monel 400 Tube Welding. Materials Performance, 59(3), 28-33.

Brown, L. M. (2018). Corrosion Resistance of Welded Monel 400 in Marine Environments. Corrosion Science, 140, 182-191.

Thompson, A. W. (2021). Filler Metal Selection for High-Performance Nickel Alloy Welding. Welding Research, 100(6), 155-163.

Davis, E. R. (2017). Optimizing GTAW Parameters for Thin-Walled Monel Tubing. Journal of Materials Engineering and Performance, 26(8), 3725-3732.

Wilson, G. H. (2022). Advances in Automated Welding of Nickel-Copper Alloys. International Journal of Advanced Manufacturing Technology, 118(5), 1587-1596.

Learn about our latest products and discounts through SMS or email