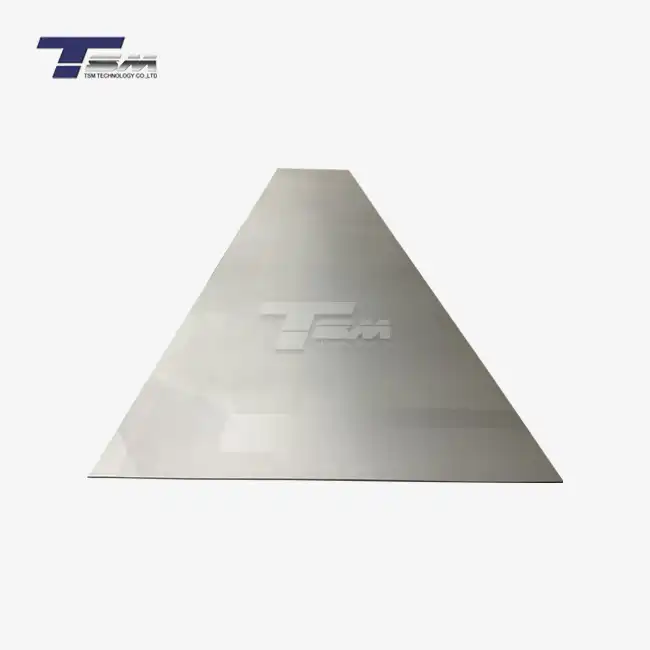

Mechanical Surface Finishing Techniques for Nickel Alloy Plates

Polishing and Buffing

Polishing and buffing are abrasive finishing methods that smooth and shine the surface of nickel alloy plates. These techniques remove minor imperfections, reduce roughness, and create a lustrous appearance. Polishing typically involves using progressively finer abrasives, while buffing employs softer materials like cloth wheels with polishing compounds. The process not only enhances aesthetics but also improves corrosion resistance by eliminating surface irregularities that could harbor contaminants.

Grinding and Lapping

Grinding and lapping are precision finishing methods used to achieve tight dimensional tolerances and superior flatness on nickel alloy plates. Grinding employs abrasive wheels to remove material and create smooth, even surfaces. Lapping, a more refined process, uses loose abrasive particles between the workpiece and a lapping plate to produce an extremely flat and smooth finish. These techniques are particularly valuable in applications requiring high-precision components made from nickel alloys.

Shot Peening and Blasting

Shot peening and blasting are impact-based surface treatments that enhance the mechanical properties of nickel alloy plates. Shot peening involves bombarding the surface with small, spherical media to induce compressive stress, improving fatigue strength and resistance to stress corrosion cracking. Blasting, using various abrasive materials, can clean surfaces, remove scale, or create a textured finish. These methods are particularly beneficial for nickel alloy components subjected to high-stress environments or requiring specific surface textures.

Chemical and Electrochemical Finishing Methods for Nickel Alloy Plates

Passivation

Passivation is a chemical treatment that enhances the corrosion resistance of nickel alloy plates by forming a protective oxide layer on the surface. This process involves immersing the alloy in an oxidizing acid solution, typically nitric or citric acid, which removes free iron and other contaminants while promoting the formation of a passive film. Passivation is crucial for maintaining the inherent corrosion resistance of nickel alloys, especially in aggressive environments encountered in chemical processing and marine applications.

Electropolishing

Electropolishing is an electrochemical process that selectively removes material from the surface of nickel alloy plates, resulting in a smooth, bright finish. The workpiece is immersed in an electrolyte solution and connected as the anode in an electrical circuit. When current is applied, metal ions are selectively dissolved from the surface, preferentially removing high points and imperfections. This technique not only improves surface finish but also enhances corrosion resistance, reduces microscopic cracks, and creates a more hygienic surface, making it ideal for applications in the food processing and pharmaceutical industries.

Electroplating

Electroplating is a versatile finishing method used to deposit a thin layer of metal onto nickel alloy plates, enhancing their surface properties. This process involves immersing the workpiece in an electrolyte solution containing dissolved metal ions and applying an electric current. Common plating materials for nickel alloys include gold, silver, and chromium. Electroplating can improve wear resistance, electrical conductivity, and corrosion protection while also allowing for customized aesthetic appearances. This technique is widely used in electronics, aerospace, and decorative applications involving nickel alloy components.

Advanced Surface Finishing Technologies for Nickel Alloy Plates

Laser Surface Treatment

Laser surface treatment is an innovative finishing method that uses focused laser energy to modify the surface properties of nickel alloy plates. This technique can achieve various effects, including hardening, alloying, and texturing. Laser hardening selectively heats and rapidly cools the surface, increasing hardness and wear resistance without affecting the bulk material. Laser alloying can introduce beneficial elements into the surface layer, enhancing properties like corrosion resistance. Additionally, laser texturing can create precise micro-patterns on the surface, improving tribological properties or creating functional surfaces for specific applications.

Plasma Nitriding

Plasma nitriding is a thermochemical surface treatment that enhances the hardness, wear resistance, and fatigue strength of nickel alloy plates. This process involves exposing the workpiece to a nitrogen-rich plasma at elevated temperatures. The nitrogen atoms diffuse into the surface of the alloy, forming nitrides and creating a hardened layer. Plasma nitriding offers advantages over traditional gas nitriding, including better control over the process, lower treatment temperatures, and reduced distortion. This method is particularly beneficial for nickel alloy components used in high-wear applications or those requiring improved tribological properties.

Physical Vapor Deposition (PVD) Coating

Physical Vapor Deposition (PVD) is an advanced coating technique used to apply thin, high-performance films to nickel alloy plates. In this process, the coating material is vaporized in a vacuum chamber and deposited onto the substrate surface. PVD coatings can significantly enhance surface hardness, wear resistance, and corrosion protection while maintaining tight dimensional tolerances. Common PVD coatings for nickel alloys include titanium nitride (TiN), chromium nitride (CrN), and diamond-like carbon (DLC). These coatings find applications in cutting tools, aerospace components, and decorative finishes where exceptional surface properties are required.

Conclusion

Surface finishing methods for nickel alloy plates encompass a wide range of techniques, each offering unique benefits and applications. From traditional mechanical processes to advanced chemical and physical treatments, these methods play a crucial role in optimizing the performance and longevity of nickel alloy components. By carefully selecting and applying the appropriate finishing technique, manufacturers can enhance corrosion resistance, improve wear properties, and achieve desired aesthetic qualities. As technology continues to advance, new and innovative surface finishing methods are likely to emerge, further expanding the possibilities for nickel alloy plate applications across various industries.

FAQs

What are the most common surface finishing methods for nickel alloy plates?

Common methods include polishing, grinding, passivation, electropolishing, and electroplating.

How does passivation improve the corrosion resistance of nickel alloy plates?

Passivation forms a protective oxide layer on the surface, enhancing the alloy's natural corrosion resistance.

Can surface finishing methods affect the mechanical properties of nickel alloy plates?

Yes, some methods like shot peening and plasma nitriding can improve fatigue strength and wear resistance.

Expert Nickel Alloy Plate Surface Finishing Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing superior nickel alloy plates with exceptional surface finishes. Our state-of-the-art facility and expert team ensure the highest quality in every product. Whether you need polished, passivated, or custom-finished nickel alloy plates, we have the capabilities to meet your specific requirements. Contact us at info@tsmnialloy.com to discuss your nickel alloy needs and discover how our advanced finishing solutions can enhance your projects.

References

Smith, J.R. (2020). "Advanced Surface Finishing Techniques for Nickel Alloys in Aerospace Applications." Journal of Materials Engineering and Performance, 29(8), 5012-5025.

Chen, L.Y., et al. (2019). "Electrochemical Surface Finishing of Nickel-Based Superalloys: A Comprehensive Review." Corrosion Science, 145, 70-84.

Thompson, A.W. (2018). "Mechanical Surface Treatments for Enhancing Fatigue Resistance of Nickel Alloy Components." International Journal of Fatigue, 108, 35-46.

Patel, R.K., & Davis, M.E. (2021). "Innovations in PVD Coatings for Nickel Alloy Substrates." Surface and Coatings Technology, 405, 126521.

Yamamoto, H., et al. (2017). "Laser Surface Modification of Nickel Alloys: Microstructure and Properties." Materials Science and Engineering: A, 702, 206-213.

Garcia-Alonso, M.C., et al. (2022). "Surface Finishing Methods for Biomedical Nickel Alloys: Impact on Corrosion Resistance and Biocompatibility." Acta Biomaterialia, 140, 89-104.