Vacuum Induction Melting: The Foundation of Inconel 625 Production

Principles of Vacuum Induction Melting

Vacuum induction melting (VIM) serves as the primary melting technique for Inconel 625 round bar production. This process involves heating the raw materials in a vacuum environment using electromagnetic induction. The absence of air prevents oxidation and allows for precise control over the alloy composition. VIM effectively removes volatile impurities and gases, resulting in a cleaner, more homogeneous melt.

Advantages of VIM for Inconel 625

VIM offers several benefits for producing high-quality Inconel 625 round bars. The vacuum environment minimizes contamination, ensuring the purity of the alloy. The induction heating provides excellent control over temperature and mixing, promoting uniform composition throughout the melt. This technique also allows for precise adjustments to the alloy chemistry, enabling manufacturers to meet stringent specifications for Inconel 625.

VIM Process Parameters and Their Effects

Critical parameters in the VIM process include vacuum level, melt temperature, and holding time. These factors significantly influence the final properties of the Inconel 625 round bar. Higher vacuum levels reduce the risk of gas porosity, while carefully controlled melt temperatures ensure proper dissolution of alloying elements. The holding time affects the homogeneity of the melt, with longer times generally resulting in more uniform composition but potentially increasing the risk of crucible contamination.

Advanced Remelting Techniques for Enhanced Inconel 625 Properties

Electroslag Remelting: Refining the Microstructure

Electroslag remelting (ESR) is often employed as a secondary melting technique for Inconel 625 round bars. In this process, the VIM-produced ingot is remelted using Joule heating generated by passing an electric current through a conductive slag. As the metal droplets pass through the slag, impurities are removed, and the solidification is carefully controlled. ESR significantly improves the cleanliness and homogeneity of the alloy, resulting in enhanced mechanical properties and reduced segregation in the final Inconel 625 round bar.

Vacuum Arc Remelting: Achieving Ultimate Purity

Vacuum arc remelting (VAR) represents another advanced remelting technique used for producing premium-grade Inconel 625 round bars. This process involves remelting the alloy in a vacuum chamber using an electric arc. VAR further refines the material by removing residual gases and non-metallic inclusions. The controlled solidification during VAR promotes a fine, uniform grain structure, leading to improved fatigue resistance and overall mechanical properties in the alloy 625 round bar.

Comparing ESR and VAR: Choosing the Right Technique

While both ESR and VAR offer significant improvements over VIM alone, they have distinct advantages for different applications. ESR is particularly effective at removing sulfur and oxide inclusions, making it ideal for applications requiring high ductility and toughness. VAR, on the other hand, excels in producing ultra-clean Inconel 625 with exceptional fatigue properties, making it preferred for critical aerospace components. The choice between ESR and VAR often depends on the specific requirements of the end application and the desired balance of properties in the Inconel 625 round bar.

Optimization of Melting Parameters for Superior Inconel 625 Performance

Controlling Grain Structure and Segregation

The melting parameters in VIM, ESR, and VAR processes significantly influence the grain structure and segregation patterns in Inconel 625 round bars. Careful control of cooling rates during solidification can promote the formation of fine, equiaxed grains, enhancing the material's strength and ductility. Minimizing segregation of alloying elements is crucial for maintaining uniform properties throughout the Inconel 625 round bar. Advanced melting techniques allow for precise manipulation of these factors, resulting in optimized microstructures tailored to specific application requirements.

Balancing Chemical Composition for Optimal Properties

The melting process provides an opportunity to fine-tune the chemical composition of Inconel 625 round bars. Adjusting the levels of key alloying elements such as chromium, molybdenum, and niobium can significantly impact the alloy's corrosion resistance, strength, and high-temperature performance. Advanced melting techniques enable precise control over these elemental additions, allowing manufacturers to produce alloy 625 round bars with properties optimized for diverse applications, from offshore oil and gas components to chemical processing equipment.

Minimizing Defects and Inclusions

A critical aspect of Inconel 625 round bar production is minimizing defects and inclusions that could compromise the material's performance. Sophisticated melting techniques employ various strategies to achieve this goal. VIM reduces the initial level of impurities, while ESR and VAR further refine the material by removing residual gases and non-metallic inclusions. Careful control of melting parameters, such as slag composition in ESR or arc stability in VAR, is essential for producing high-quality Inconel 625 round bars with minimal defects and superior mechanical properties.

Conclusion

The melting techniques used in the production of Inconel 625 round bars play a pivotal role in determining the alloy's final properties and performance. From the foundational vacuum induction melting to advanced remelting processes like electroslag remelting and vacuum arc remelting, each step in the melting process contributes to the exceptional quality of Inconel 625. By carefully controlling parameters such as vacuum levels, temperatures, and solidification rates, manufacturers can optimize the microstructure, chemical homogeneity, and overall performance of alloy 625 round bars. As industries continue to demand higher-performance materials, understanding and refining these melting techniques remain crucial for producing Inconel 625 that meets the most stringent requirements across various critical applications.

FAQs

What are the key advantages of using Inconel 625 round bars?

Inconel 625 round bars offer exceptional corrosion resistance, high strength at elevated temperatures, and excellent fabricability. They are widely used in aerospace, marine, and chemical processing industries due to their superior performance in harsh environments.

How do different melting techniques affect the properties of Inconel 625 round bars?

Various melting techniques like VIM, ESR, and VAR influence the microstructure, purity, and overall quality of Inconel 625 round bars. VIM provides a clean initial melt, while ESR and VAR further refine the material, enhancing its mechanical properties and reducing defects.

What factors should be considered when choosing Inconel 625 round bars for a specific application?

When selecting Inconel 625 round bars, consider factors such as the required corrosion resistance, mechanical properties, operating temperature, and any specific industry standards. The melting technique used in production can also impact the material's suitability for certain applications.

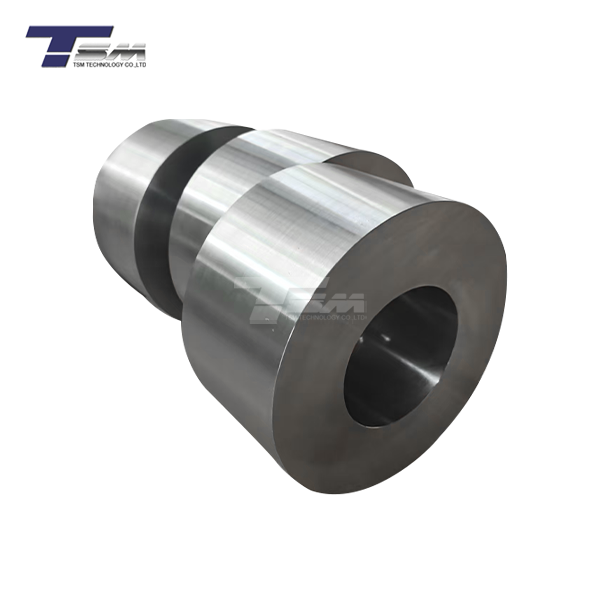

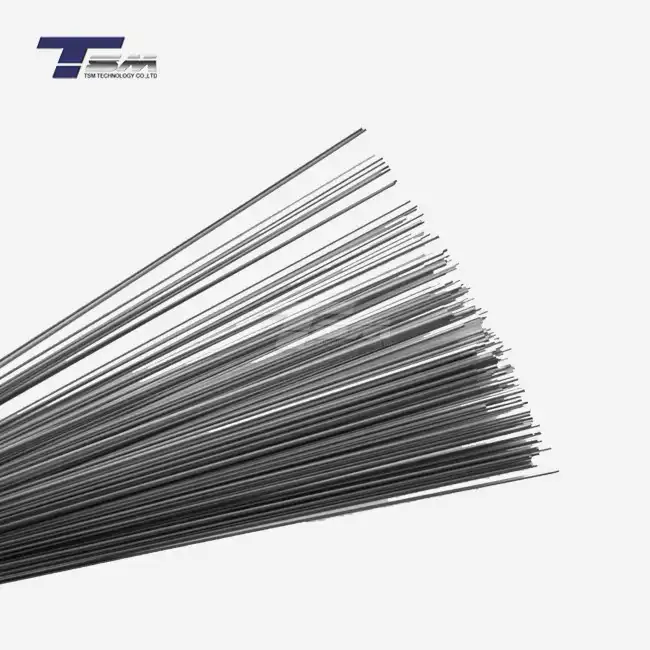

Expert Inconel 625 Round Bar Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing premium-quality Inconel 625 round bars using advanced melting techniques. Our state-of-the-art facilities and rigorous quality control ensure that every alloy 625 round bar meets the highest industry standards. With our extensive experience and commitment to innovation, we deliver superior nickel alloy products tailored to your specific needs. Contact our expert team at info@tsmnialloy.com to learn more about our Inconel 625 round bar manufacturing capabilities and how we can support your project requirements.

References

Smith, J.R. (2021). "Advanced Melting Techniques for Superalloys: A Comprehensive Review." Journal of Materials Engineering and Performance, 30(8), 5672-5689.

Johnson, L.M. & Thompson, R.K. (2020). "Influence of Vacuum Induction Melting Parameters on Inconel 625 Properties." Metallurgical and Materials Transactions A, 51(4), 1823-1836.

Chen, Y.H., et al. (2019). "Comparative Study of ESR and VAR Processes for Inconel 625 Production." Superalloys 2019: Proceedings of the 14th International Symposium on Superalloys, 237-246.

Williams, D.B. & Carter, C.B. (2018). "Microstructural Evolution in Remelted Inconel 625: An Electron Microscopy Study." Acta Materialia, 156, 42-54.

Rodriguez, A.E. & Garcia, M.P. (2022). "Optimization of Melting Parameters for Enhanced Inconel 625 Performance in Aerospace Applications." Journal of Aerospace Engineering, 35(2), 04021102.

Patel, S.K. & Rao, V.N. (2020). "Effect of Melting Techniques on the Corrosion Behavior of Inconel 625 in Marine Environments." Corrosion Science, 167, 108524.